Method for generating electricity by using low-pressure saturated steam

A steam and low-pressure technology, which is applied in the direction of steam engine devices, engine components, machines/engines, etc., can solve problems such as waste of resources, complex systems, and large pollution, and achieve simple production and maintenance, low system complexity, and high cascade utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

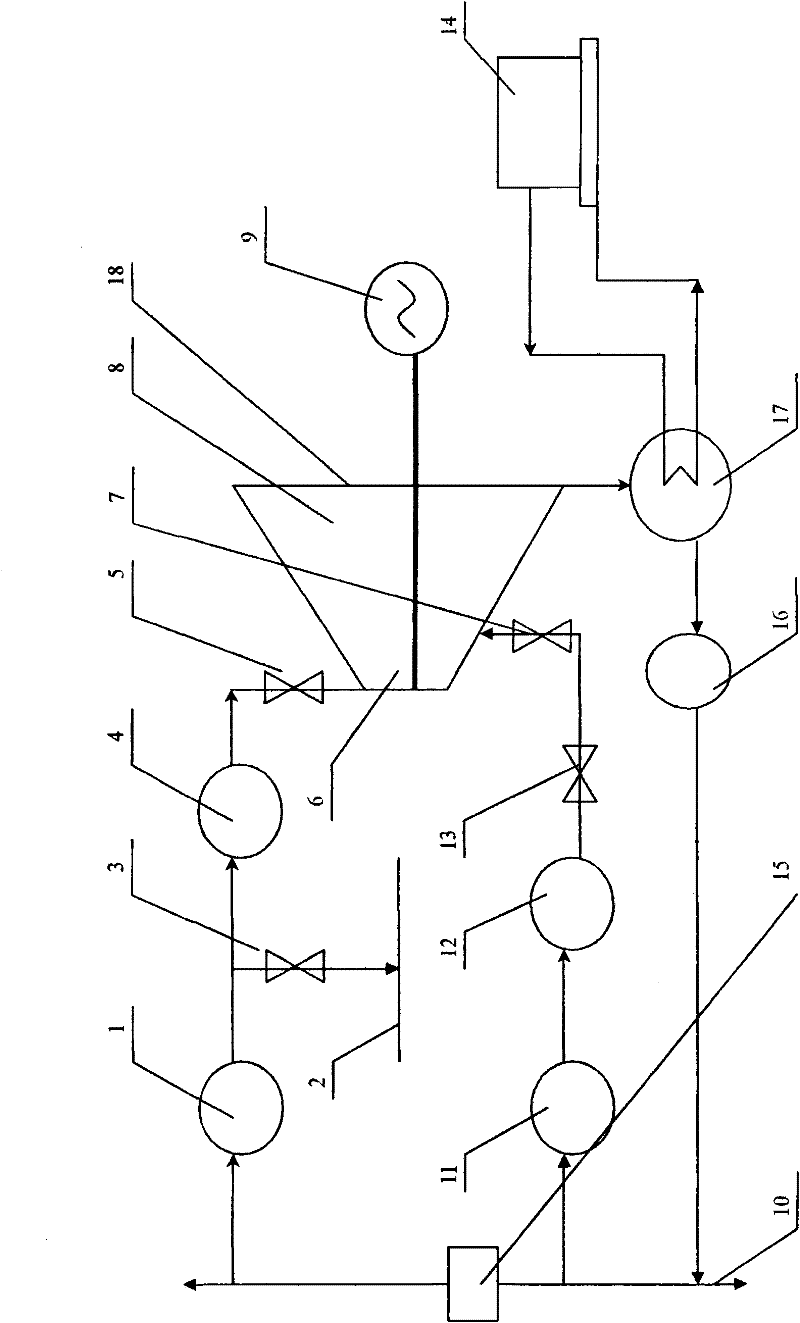

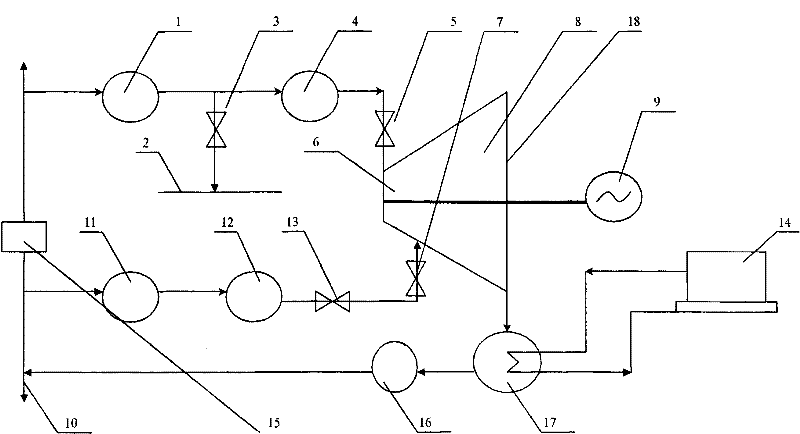

[0018] Design idea of the present invention is:

[0019] 1 thermal system

[0020] The main steam and supplementary steam enter the steam turbine to generate power, and the exhaust steam enters the condenser to condense and collect in the hot well. The condensed water passes through the condensed water pump and is sent to the plant soft water station for recycling through the newly laid pipeline. The main steam comes from the saturated steam produced by the evaporative cooling of the converter, and a pipeline is connected to the power station. At the same time, a set of self-operated steam pressure regulating valves are installed on the pipeline to increase and stabilize the main steam inlet pressure of the unit. The supplementary steam comes from the vaporized steam of the heating furnace, and the pipeline is connected to the power station. In view of the disadvantage of high water content in saturated steam, a steam-water separation device is added on the steam inlet side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com