High-temperature resistant film-coated special bag dust collection equipment

A technology of dust removal equipment and special bags, which is applied in the field of smoke and dust control equipment, can solve the problems of large steel consumption, high cost, and complex equipment structure, and achieve the effects of prolonging service life, reducing floor space, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

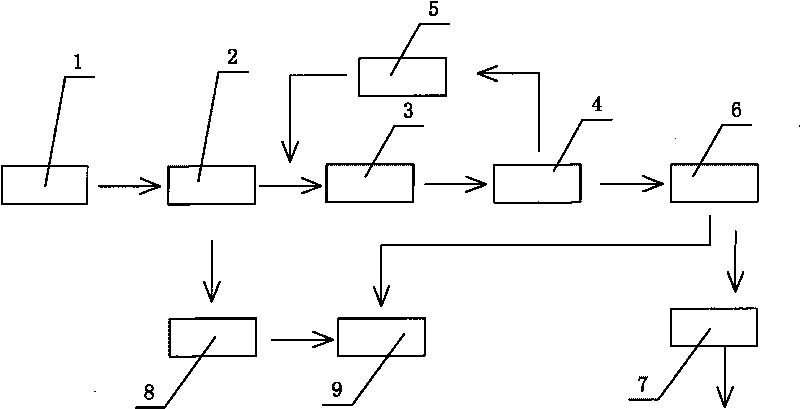

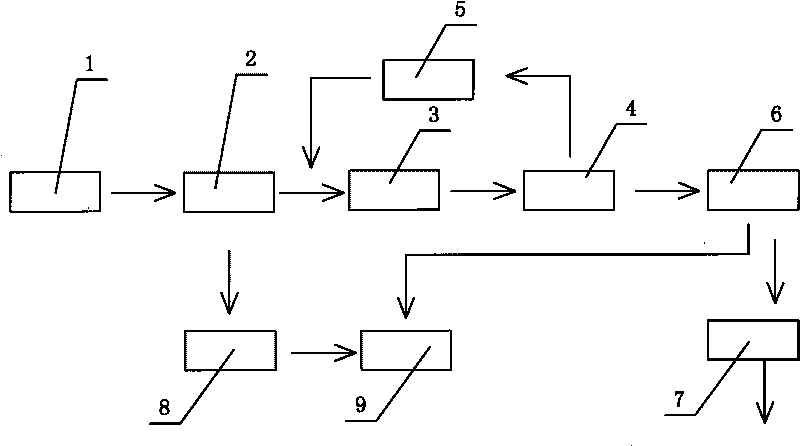

[0007] The following will be further explained in conjunction with the attached drawings: Taking the calcium carbide furnace kiln specification as 12500KVA as an example, the furnace body 1 is connected to the spark trap 2 through the main pipeline, and connected to the frequency conversion main fan 3 through the main pipeline. The frequency conversion main fan 3 adopts The frequency conversion motor fan, the frequency conversion main fan 3 is connected to the three-way valve 4 by the pipe, and the ordinary fan 5 is connected to the ordinary fan 5 by the variable diameter pipe, and the back suction is automatically cleaned, and then the spark trap 2 is connected to the main fan by the pipe main pipeline. And the three-way valve 4 is connected to the special film-coated filter bag dust collector 6. The total number of rooms in the dust collector is 7-9 rooms, and each room is equipped with 46-58 special film-coated filter bags. The material of the filter bags is glass fiber coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com