Lead-acid ultra-battery

A super lead-acid battery and lead powder technology, applied in the direction of lead-acid batteries, electrode carriers/collectors, etc., to achieve excellent high-rate performance, solve the effects of short life, and reduce the depth of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1, super lead-acid battery (5Ah) assembly of the present invention:

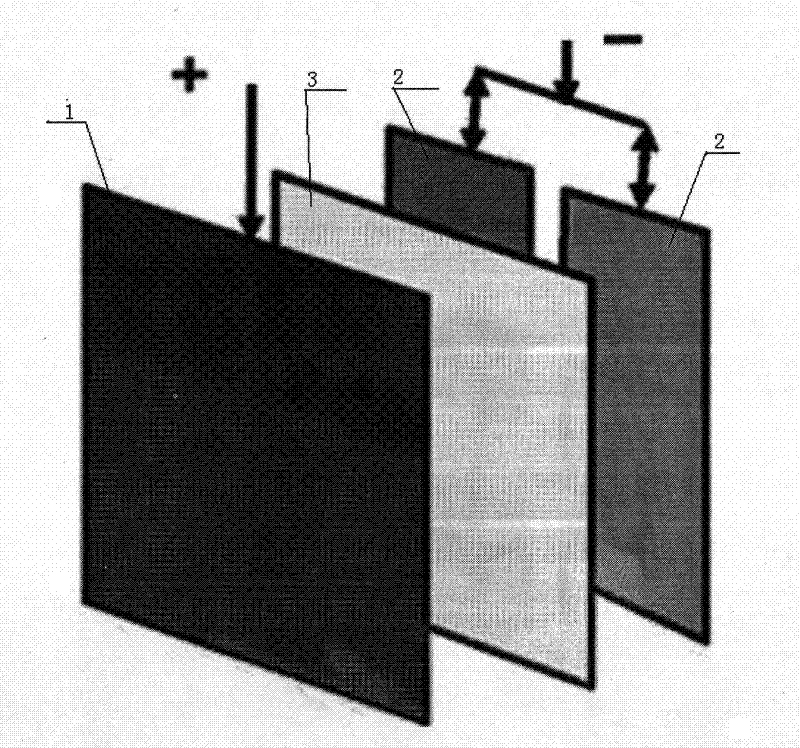

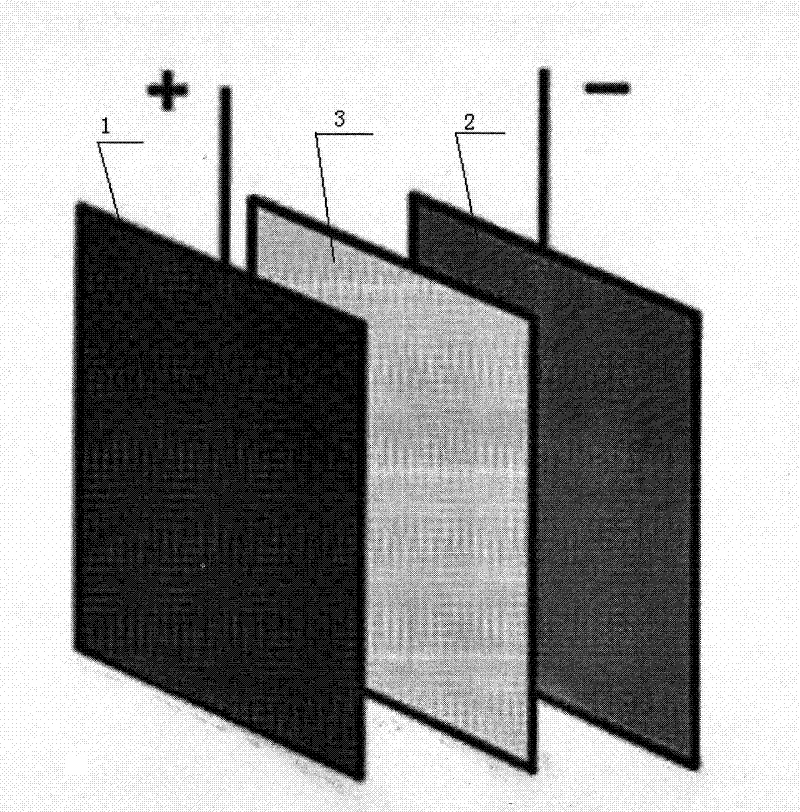

[0034] Positive plate 1 is PbO 2 , the negative plate 2 includes two pieces, one of which is a lead negative plate, and the other is a conductive polymer negative plate of conductive polyaniline (PAN), the lead negative plate and the conductive polymer negative plate are placed in parallel, and there is no gap between the two negative plates. Separator 3, two negative plates share the same PbO 2 Positive plate 1, diaphragm 3 is set between positive plate 1 and negative plate 2, press figure 1 Assemble as shown. The negative grids of the above negative plates are all made of lead-antimony alloy grids.

[0035] Wherein, the preparation of the lead negative plate: get 19.33 grams of lead powder (chemical composition Pb 2PbO) and the additive of 1.0% lead powder quality (the mass ratio of barium sulfate, humic acid and acetylene black is 1.5: 1: 1) mix uniformly , and then added to 12% H of the qualit...

Embodiment 2

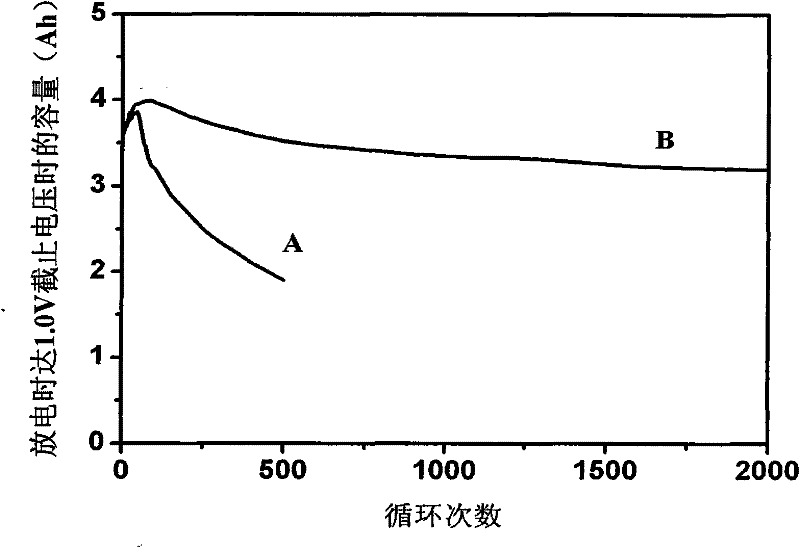

[0053] Assemble and test the super lead-acid battery in the same manner as in Example 1, except that the mass ratio of lead powder: PAN is changed to 3: 1, the initial capacity of the super lead-acid battery is 3.65Ah, and after 2000 cycles, the capacity is 3.24Ah. The retention rate was 88.8% of the initial capacity.

Embodiment 3

[0055] Assemble and test super lead-acid battery in the same manner as in Example 1, just lead powder: the mass ratio of PAN is changed into 30: 1, and the initial capacity of gained super lead-acid battery is 3.56Ah, and after 2000 cycles, capacity is 3.14Ah, The capacity retention rate was 88.2% of the initial capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com