Outdoor box type frequency conversion control station

A frequency conversion control and outdoor box technology, applied in the control system, AC motor control, control of multiple AC motors, etc., can solve the problems of high cost of motors, frequency converters and cables, large impact of power supply system, large starting current, etc., to achieve Save the amount of civil engineering, ensure stable operation, and reduce the effect of start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

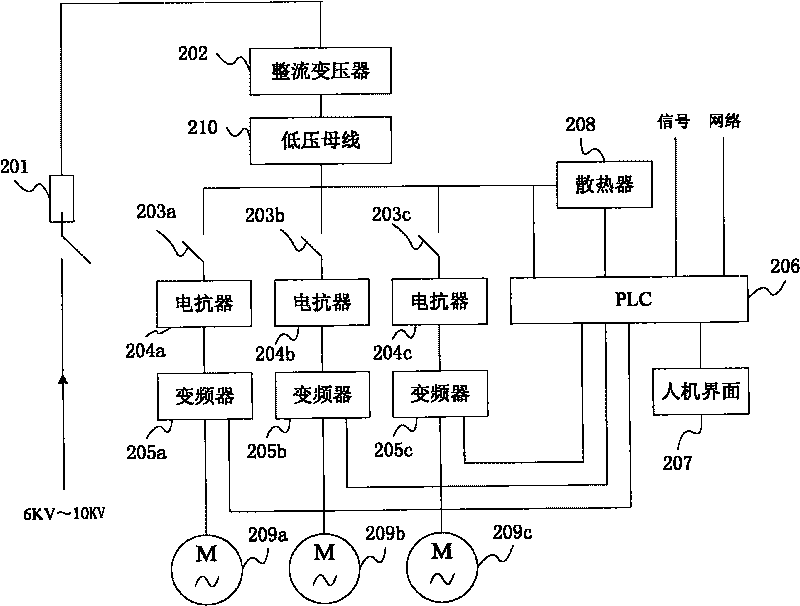

[0019] like figure 2 As shown, the outdoor box-type frequency conversion control station of this embodiment includes: a load switch 201, a rectifier transformer 202, a low-voltage busbar 210, multiple power distribution switches (203a, 203b and 203c), and multiple frequency converters ( 205a, 205b and 205c) and supporting reactors (204a, 204b and 204c), a programmable logic controller 206 (PLC) as a remote IO control device and a man-machine interface 207 for local operation, and an automatically controlled heat dissipation Device 208, the outdoor box-type frequency conversion control station can drive and control multiple motors (209a, 209b and 209c).

[0020] The programmable controller 206 has an Ethernet port and a signal port for communicating with the external network and the control system respectively. The programmable controller 206 is connected with the man-machine interface 207 and the heat dissipation device 208 , performs man-machine interaction through the man-...

Embodiment 2

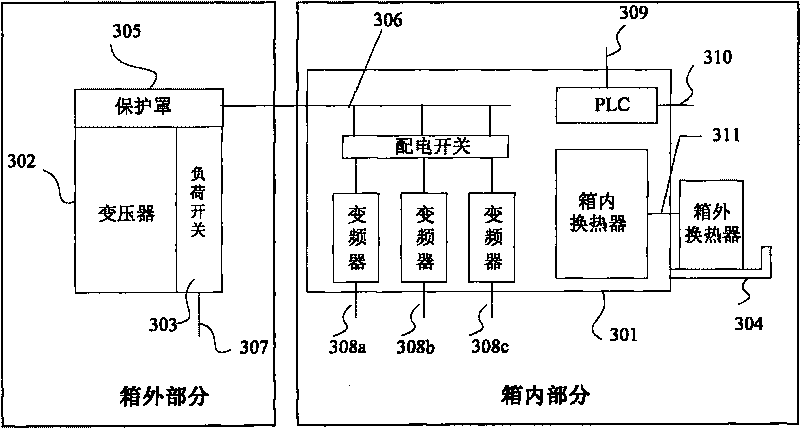

[0029] like Figure 5 As shown, the outdoor box-type frequency conversion control station of this embodiment includes an inside part and an outside part. The outside part includes: a load switch connected to the high voltage input terminal; a rectifier transformer connected to the load switch. The inner part of the box includes: a low-voltage busbar connected to the output terminal of the rectifier transformer, four power distribution switches, a cooling device and a programmable logic controller (PLC).

[0030] Each power distribution switch is connected to a frequency converter and supporting reactor; PLC is connected to 4 frequency converters and connected to the external network and remote control system through its own Ethernet port and signal interface.

[0031] The heat dissipation device can also adopt a thermal cycle cooling system (such as: air conditioner), which has an evaporator and a condenser. The air in the body dissipates heat, and the condenser (that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com