Combination for preventing and treating plant virosis and application thereof

A plant virus disease and composition technology is applied in the field of compositions for preventing and treating plant virus diseases, and achieves the effects of high activity, remarkable effect and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 plant virus inhibitor aqua (KBD aqua)

[0033] 1. Preparation of component A: Take 2.5 kg of Polygonum cuspidatum, crush it to 60 mesh, add 12.5 kg of 70% ethanol, soak it for 2 hours, extract it ultrasonically at 45°C for 2 hours, centrifuge to get the supernatant, and remove the solvent at 45°C , and dilute to 5 kg with 70% ethanol to prepare the extract of Polygonum cuspidatum (component A) for subsequent use.

[0034] 2. Preparation of Component B: Take 2 kg of soybeans and hydrolyze them under the alkaline condition of pH=11 to obtain 4 kg of plant protein hydrolyzate, i.e. plant protein amino acid liquid, then add 5 kg of saponin extract and 1 kg of tea soap (Note: saponin extract and tea saponin are both produced by Zhejiang Dongfang Tea Industry Technology Co., Ltd.), and mixed evenly to obtain a plant-derived surfactant (component B).

[0035] 3. Preparation of plant virus inhibitor: Mix 5 parts of component A, 3 parts of compon...

Embodiment 2

[0037] 1. Preparation of component A: Take 1 kg of Polygonum cuspidatum, crush it to 60 mesh, add 10 kg of 70% ethanol, soak it for 1 hour, extract it ultrasonically at 45°C for 5 hours, centrifuge to get the supernatant, and remove the solvent at 45°C , and dilute to 2 kilograms with 70% ethanol to obtain Polygonum cuspidatum extract (component A) for subsequent use.

[0038]2. Preparation of component B: take 2 kg of soybeans and hydrolyze them under the alkaline condition of pH=10 to obtain 5 kg of vegetable protein hydrolyzate, i.e. vegetable protein amino acid liquid, then add 6 kg of saponin extract and 9 kg of tea soap (Note: saponin extract and tea saponin are both produced by Zhejiang Dongfang Tea Industry Technology Co., Ltd.), and mixed evenly to obtain a plant-derived surfactant (component B).

[0039] 3. Preparation of plant virus inhibitor: Mix 1 part of component A, 3 parts of component B and 6 parts of water to make 10 kg of water agent KBD.

Embodiment 3

[0041] 1. Preparation of Component A: Take 1 kg of Polygonum cuspidatum, crush it to 60 mesh, add 5 kg of 70% ethanol, soak for 5 hours, extract it ultrasonically at 45°C for 2 hours, centrifuge to get the supernatant, and remove the solvent at 45°C , and dilute to 2 kilograms with 70% ethanol to obtain Polygonum cuspidatum extract (component A) for subsequent use.

[0042] 2. Preparation of component B: take 2 kg of soybeans and hydrolyze them under the alkaline condition of pH=12 to obtain 4 kg of plant protein hydrolyzate, i.e. plant protein amino acid liquid, then add 2 kg of saponin extract and 4 kg of tea soap (Note: saponin extract and tea saponin are both produced by Zhejiang Dongfang Tea Industry Technology Co., Ltd.), and mixed evenly to obtain a plant-derived surfactant (component B).

[0043] 3. Preparation of plant virus inhibitor: Mix 6 parts of component A, 2 parts of component B and 2 parts of water to make 10 kg of water agent KBD.

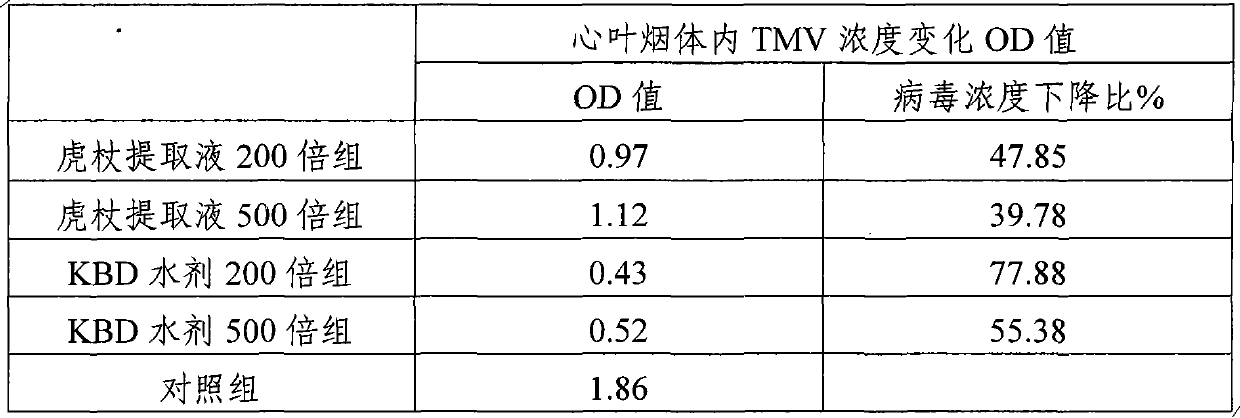

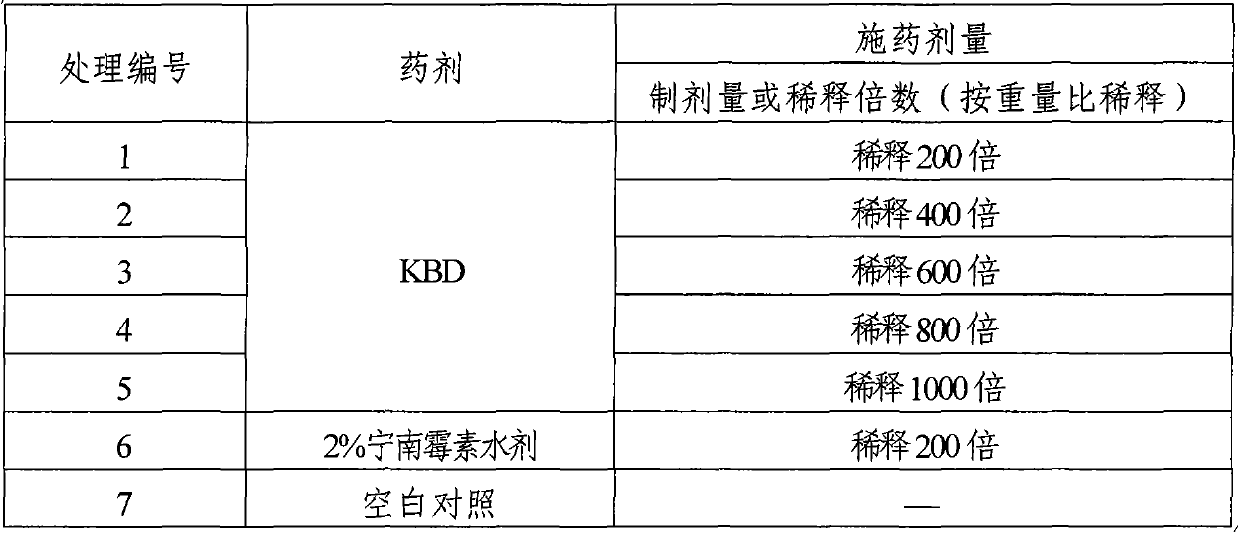

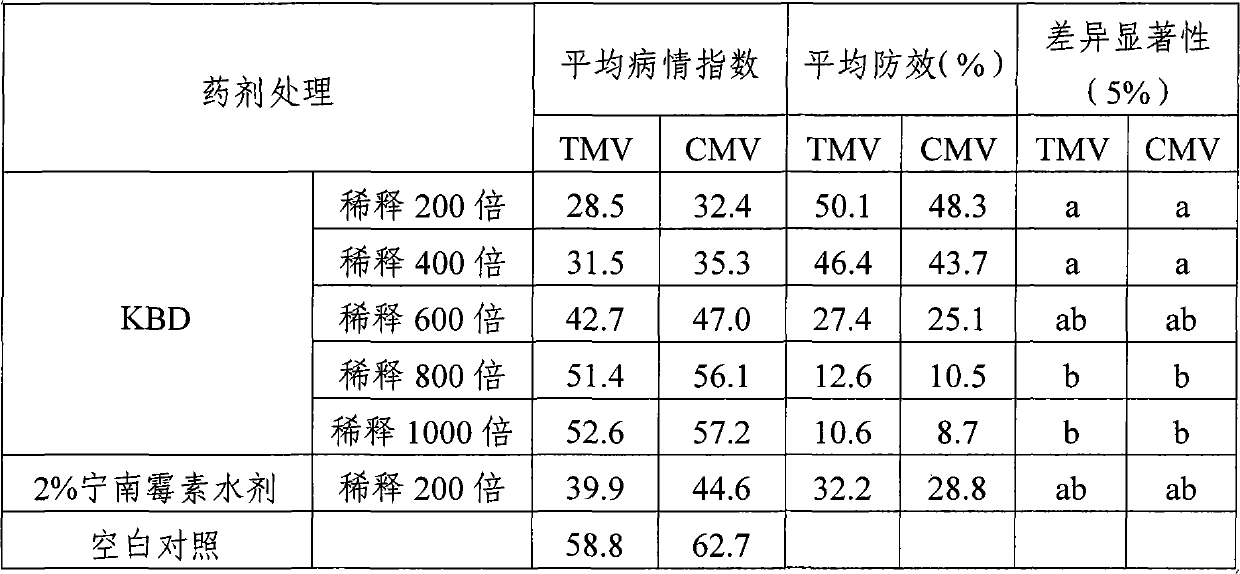

[0044] The present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com