Raw material formula of hydrophilic interaction electrochromatographic monolithic column and method for preparing same

A technology of hydrophilic interaction and monolithic column, applied in the field of electrochromatography, can solve the problems such as not obtaining good results, and achieve the effects of low cost, simple preparation method and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

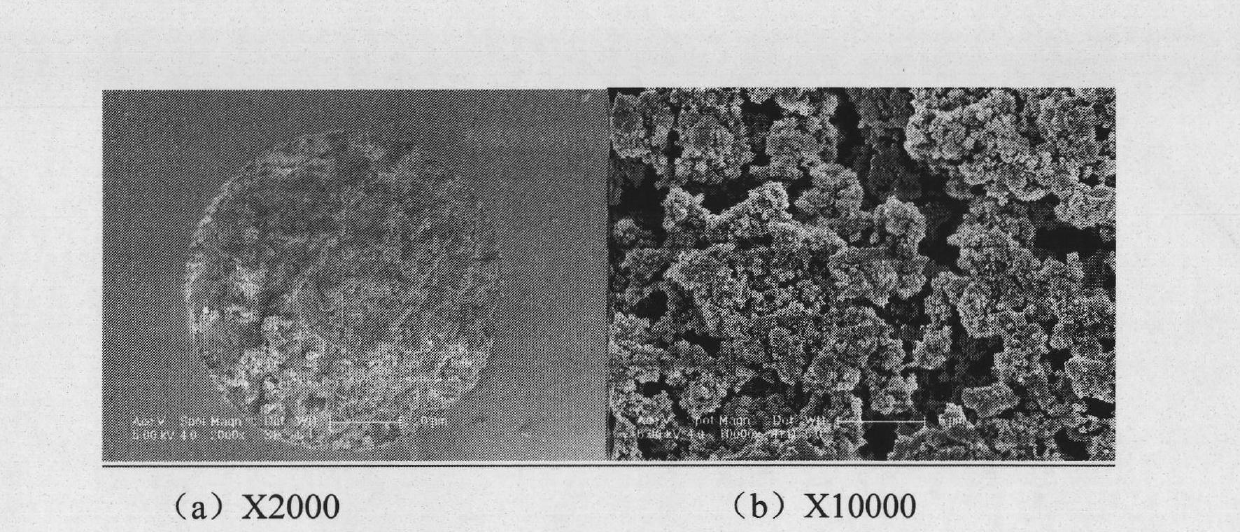

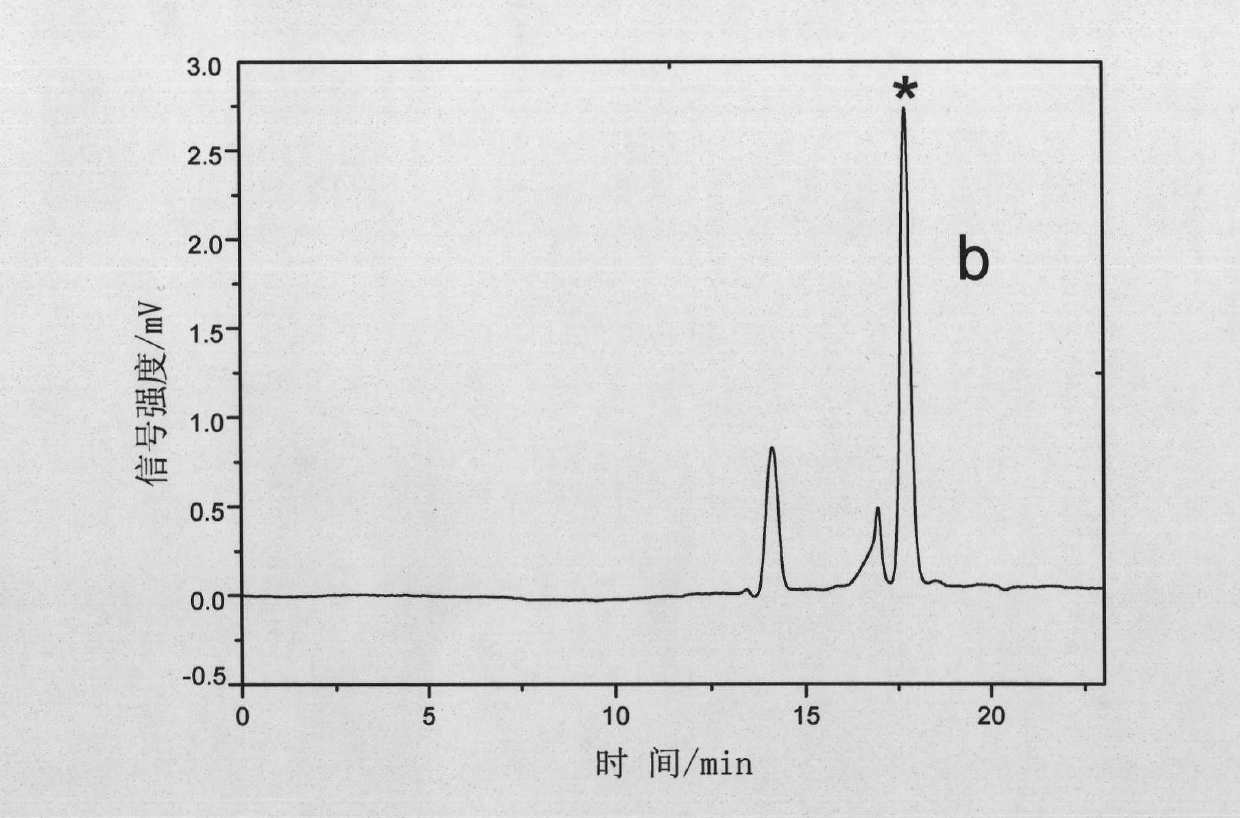

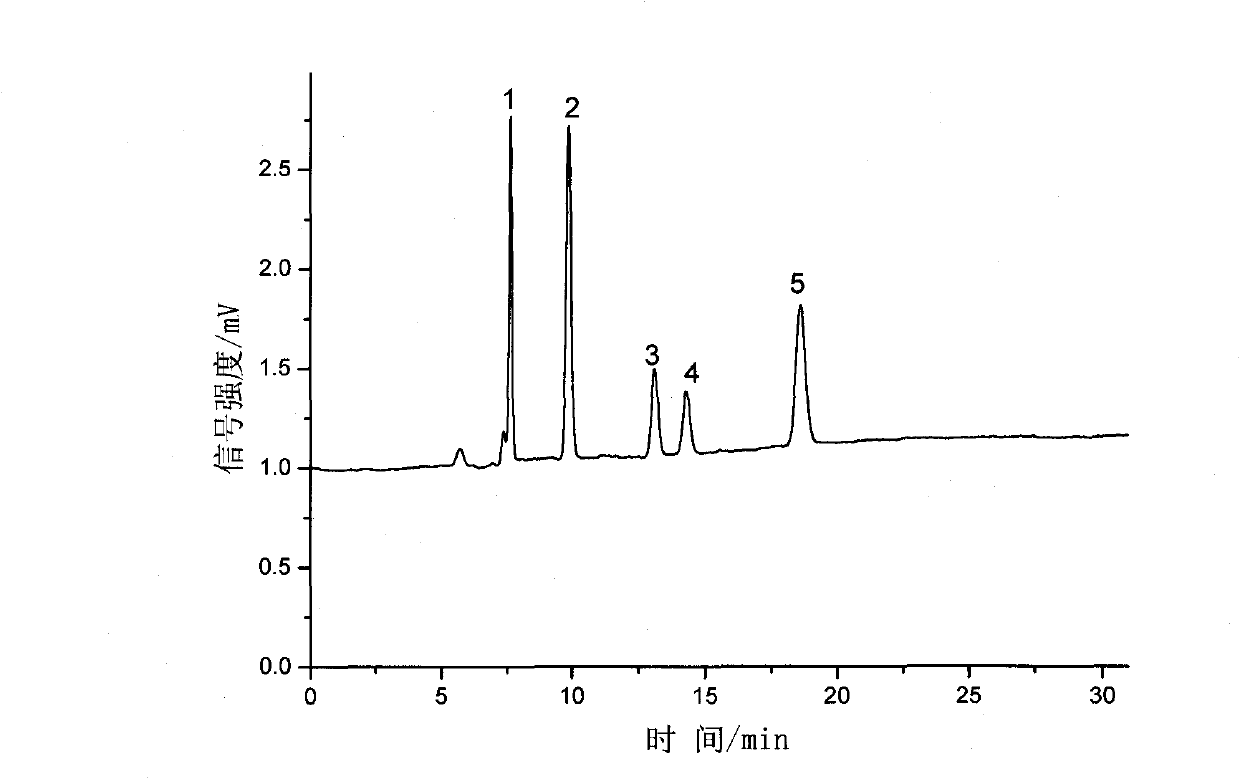

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a monolithic column of hydrophilic interaction electrochromatography, comprising the steps of:

[0031] (1) Pretreatment of the capillary: wash with 1mol / L HCl for 30min, then wash with deionized water until neutral, wash with 0.1mol / LNaOH for 3h, then wash with deionized water until neutral, then rinse with acetone for 15min, nitrogen Blow dry for later use; add a mixture of acetone and methacryloxypropyl trimethoxysilane in a volume ratio of 1:1 to the dried capillary, react in a water bath at 60°C for 24 hours, rinse with acetone for 30 minutes after the reaction, and use Blow dry with nitrogen for later use;

[0032] (2) Preparation of capillary monolithic column: mix the obtained mixture according to the raw material formula, after ultrasonic mixing for 10 minutes, pass nitrogen to remove the air in the mixture, then inject the mixture into the capillary obtained in step (1), seal both ends of the capillary, immerse React in a water bath at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com