Method for preparing active carbon with high acid group content by mixing excess sludge and corn cobs

A technology of excess sludge and acidic groups, applied in the field of activated carbon, can solve the problems of underdeveloped pore structure, low specific surface area and high ash content, and achieve the effect of strong cation exchange, strong hydrophilicity and lower raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

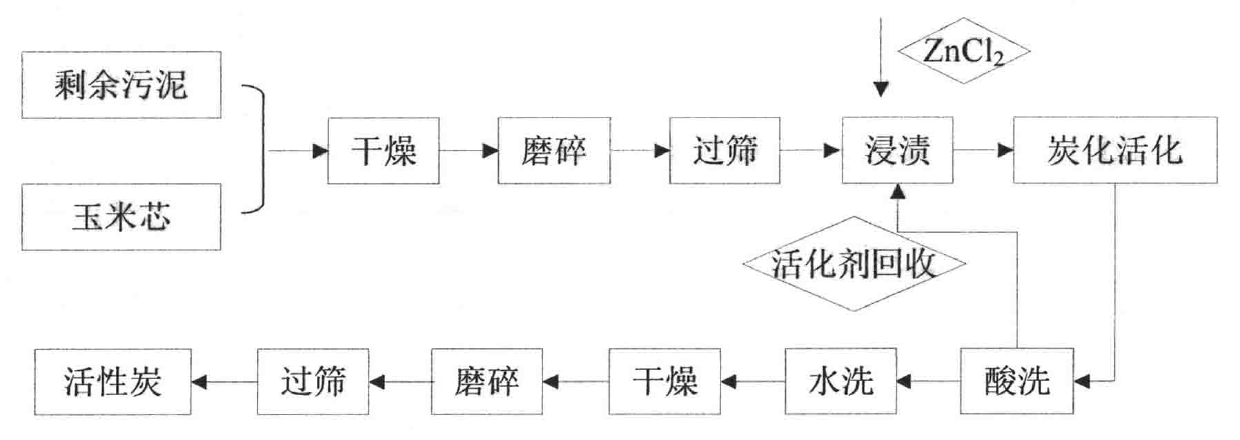

Method used

Image

Examples

Embodiment 1

[0019] The sludge and corncobs are mixed with a mass ratio of 1:1, impregnated with a zinc chloride solution with a mass ratio of zinc chloride and water of 30% for 24 hours, and the dry weight ratio of the dry sludge to zinc chloride is taken 1:0.8, remove the floating liquid, dry at 105°C for 24 hours, and send it into the muffle furnace for carbonization activation. Wherein the activation temperature is 600° C., and the activation time is 60 minutes. The iodine value of the activated carbon prepared under this condition is 678 mg / g, which is 81% of the iodine value of the commercial wood powder activated carbon measured under the same conditions. The specific surface area is 712.81m 2 g -1 , about 89.0% of the specific surface area of commercial activated carbon.

Embodiment 2

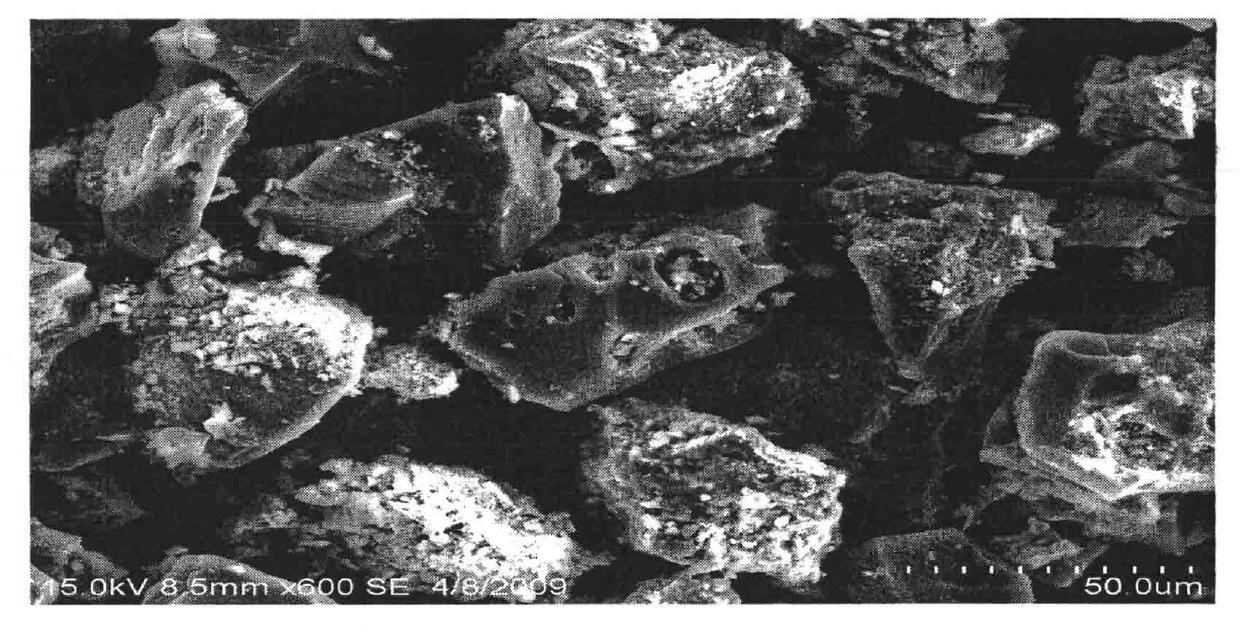

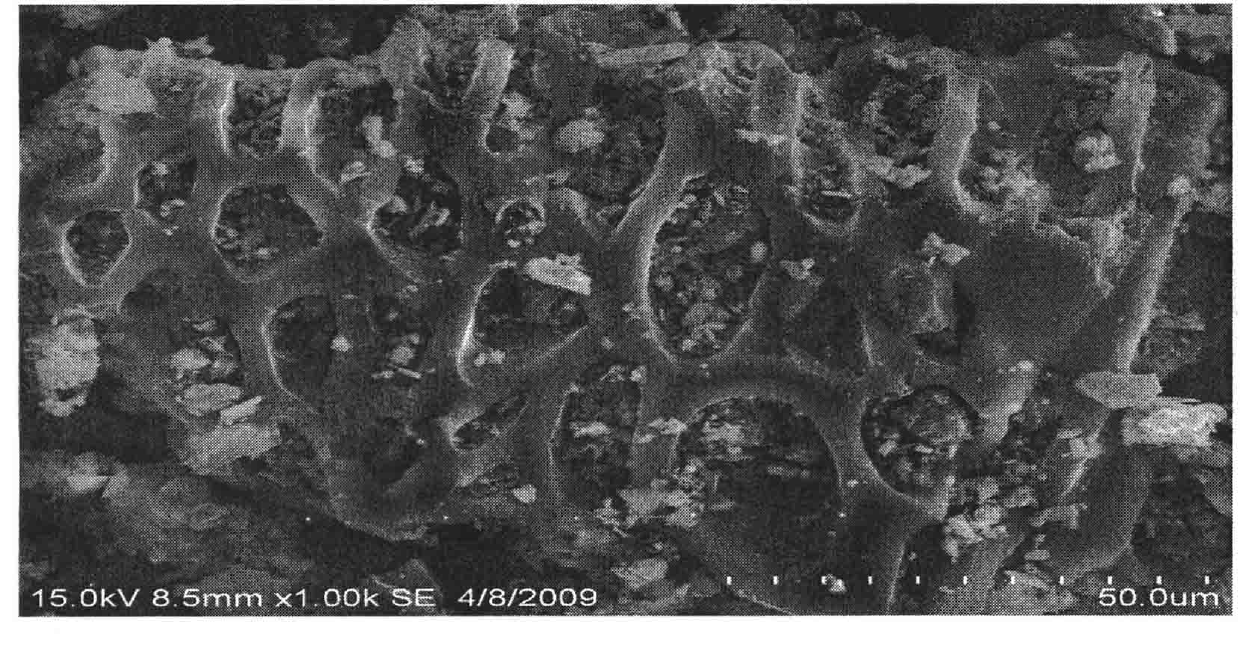

[0021] Using sludge, corn cob and the mixture of sludge and corn cob as raw materials respectively, the activation temperature is 600°C, the activation time is 60 minutes, the concentration of zinc chloride is 30%, and the ratio of zinc scrap is 1:0.8. Activated carbon was prepared under the condition of 1:1 mixing of corncob mixture, and the surface functional groups of these activated carbons were determined by Boehm titration, and compared with woody commercial activated carbon. The results are shown in Table 2. The specific operation steps are as follows:

[0022] For a certain carbon sample to be tested, accurately weigh 4 samples with a weight of 1.0g, and put them into 250ml iodine measuring bottles respectively, and then add 25ml of 0.1mol / L HCl solution, 0.1 mol / L NaOH solution, 0.1mol / L Na 2 CO 3 solution, 0.1mol / L NaHCO 3 The solution was shaken for 30 minutes, and then filtered in a constant temperature tank at 25°C for 48 hours to balance. Accurately measure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com