Method for preparing highly hydrogenated segmented copolymer

A technology of block copolymers and hydrogenated blocks, which is applied in the field of mass production of highly hydrogenated vinyl aromatic/conjugated diene block copolymers, which can solve problems such as poor processability, low heat resistance, and poor light stability. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

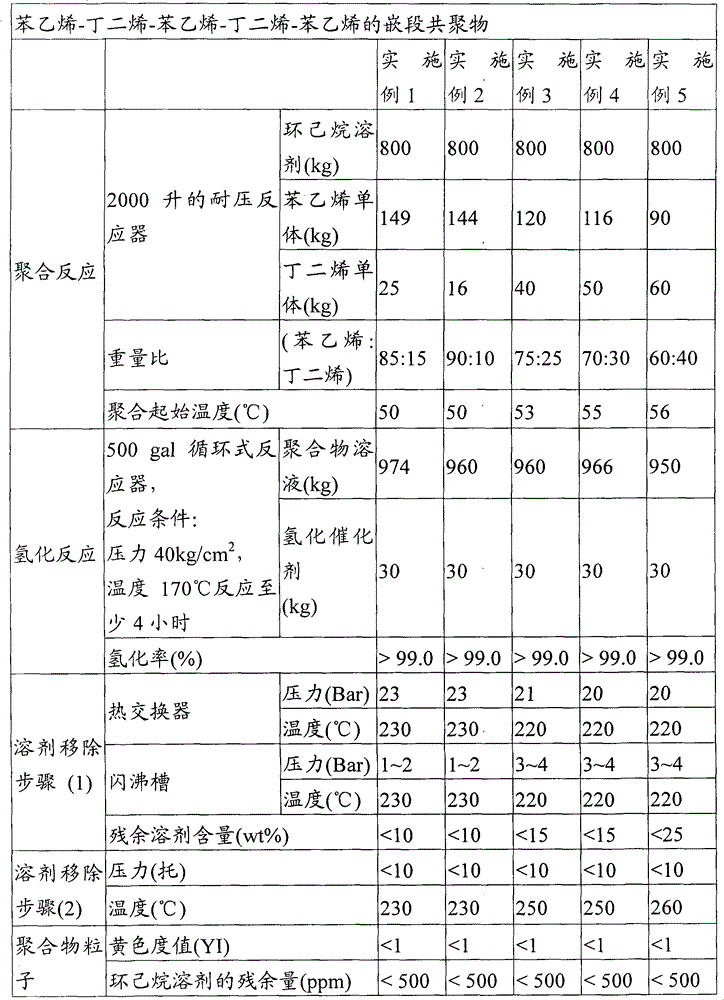

Examples

Embodiment

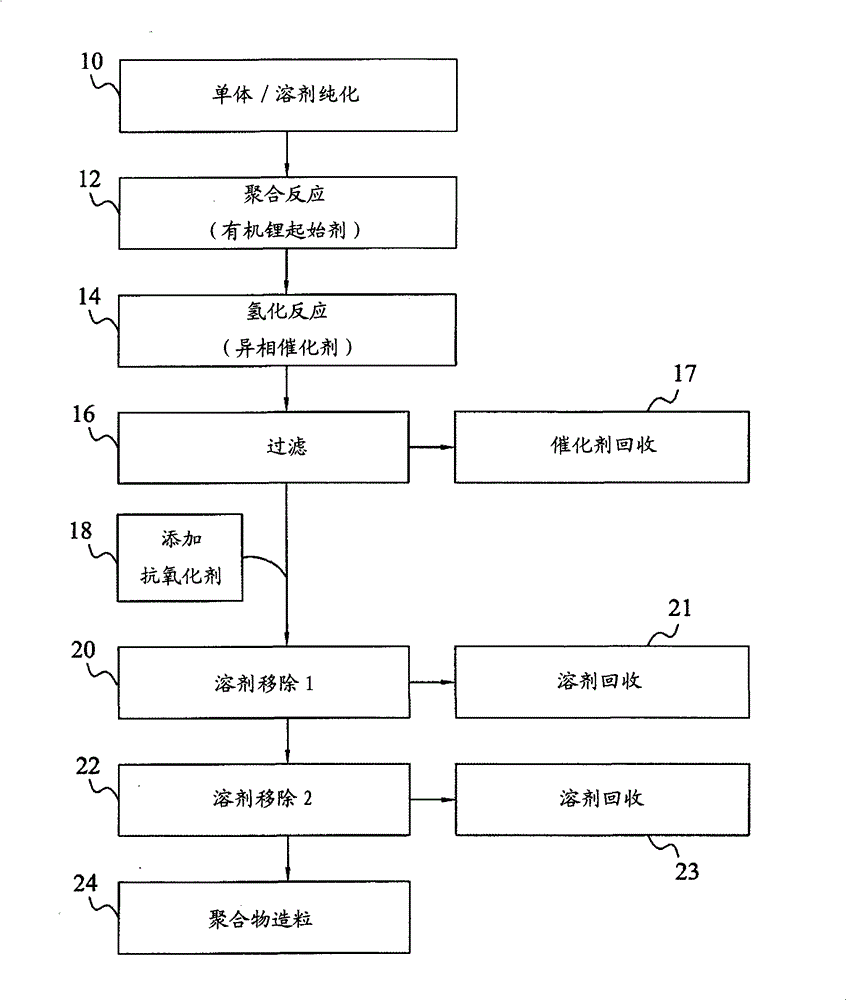

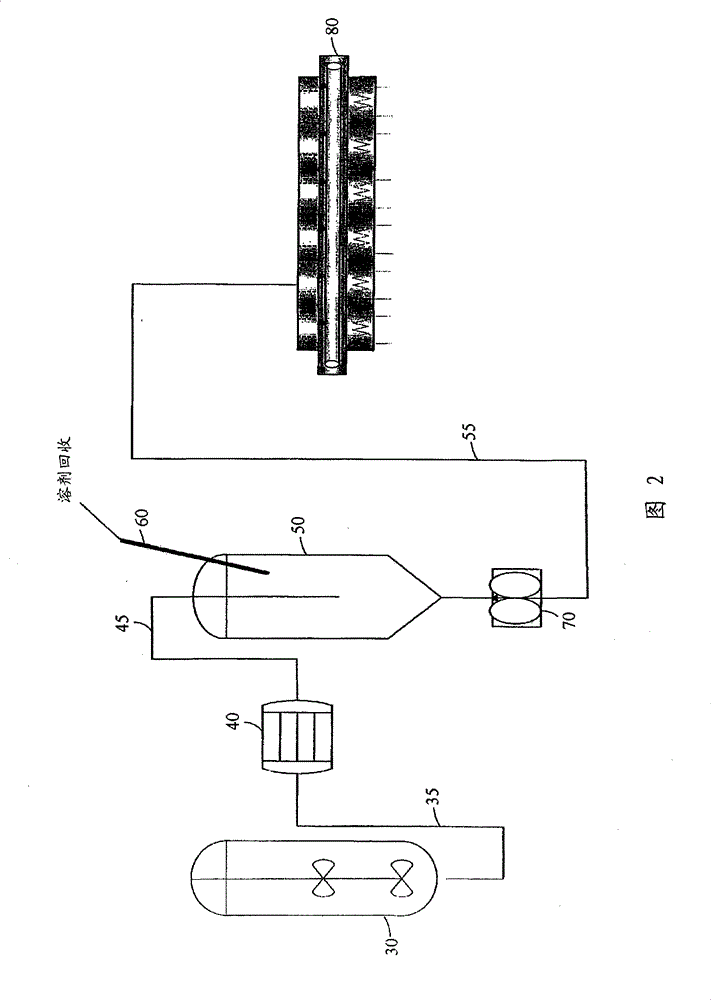

[0053] In order to make the present invention more understandable, the following detailed descriptions all refer to figure 1 and figure 2 ,in figure 1 It is a flow diagram of a method for producing a highly hydrogenated vinyl aromatic / conjugated diene block copolymer provided according to an embodiment of the present invention, and figure 2 Then it is a schematic diagram of a devolatilization system provided according to an embodiment of the present invention.

[0054] The presence of impurities in solvents and monomers and water, if they enter the polymerization system before being removed, will affect the activity of the polymerization catalyst. And a large amount of impurities will make the catalyst invalid or cause the ideal molecular weight of the polymer solution to be difficult to obtain.

[0055] The drying tower filled with activated alumina after drying and dehydration can generally be used to absorb moisture and impurities in solvents and monomers. Although th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com