Double-drive planetary transmission driving system of shield machine

A planetary speed change, transmission system technology, applied in mining equipment, tunnels, earth-moving drilling and other directions, can solve the problems of increasing volume, single output state, reducing maintenance and repair costs, etc., to reduce material costs and manufacturing costs, reduce Difficulty in installation and disassembly, the effect of reducing maintenance and repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

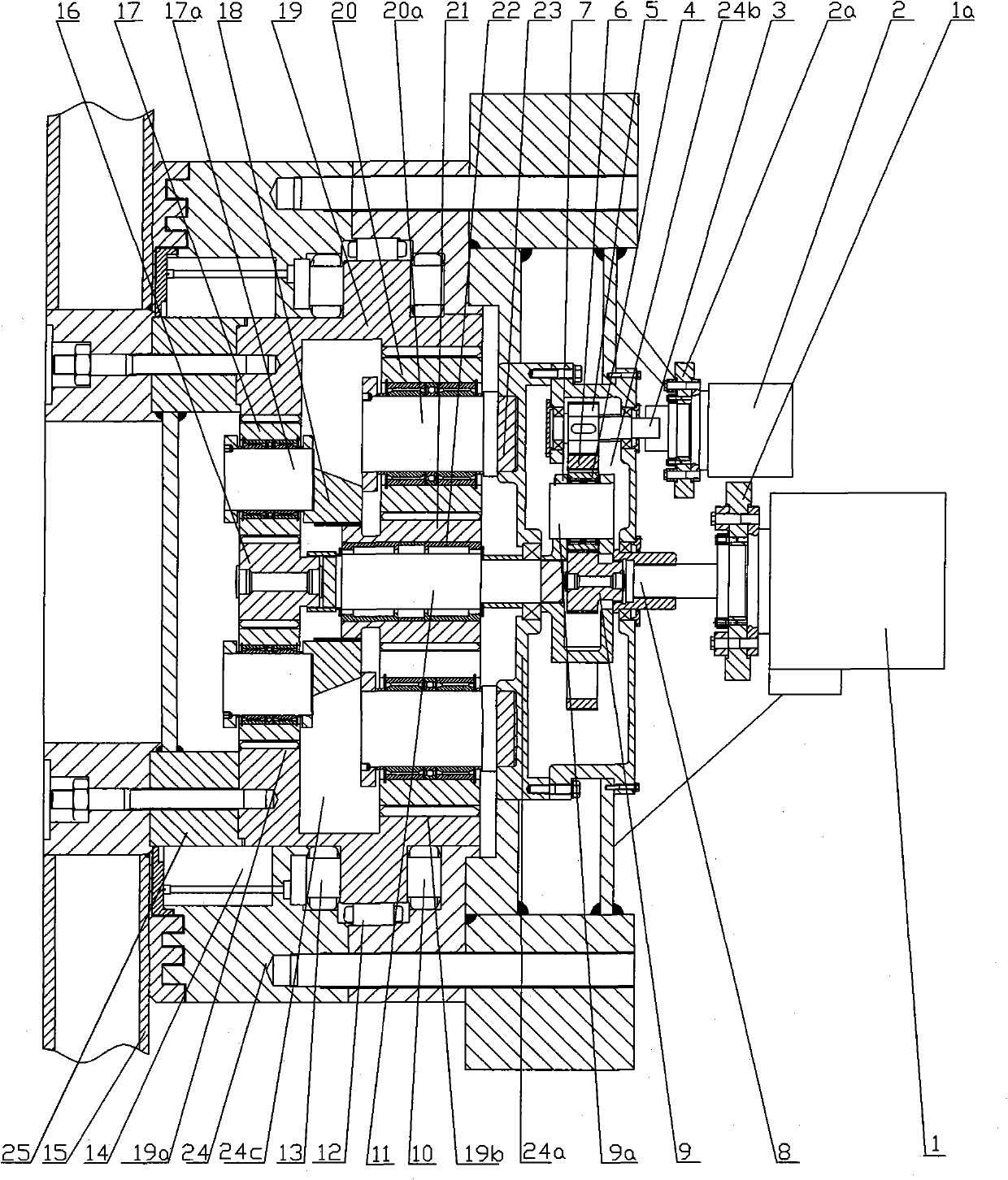

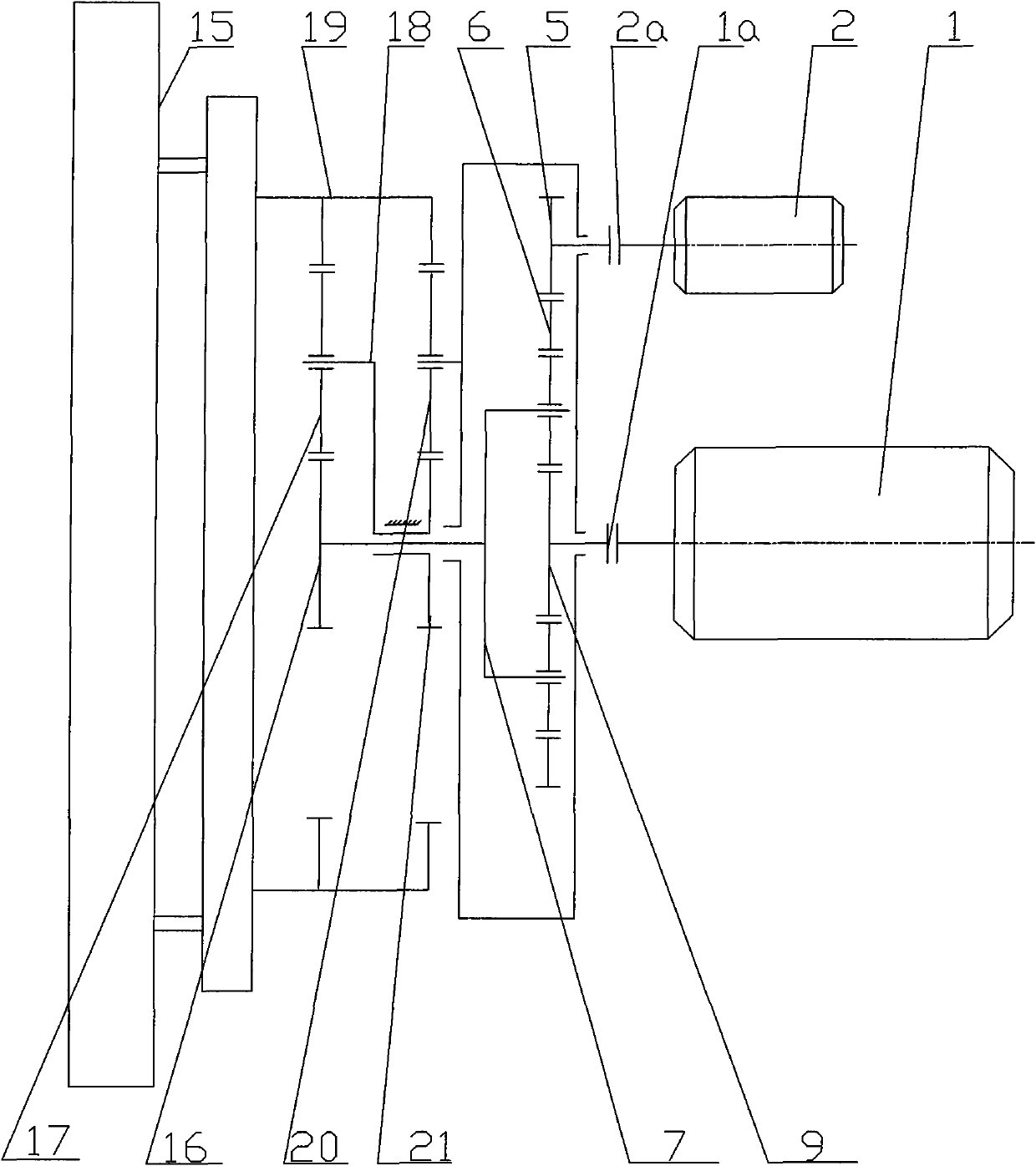

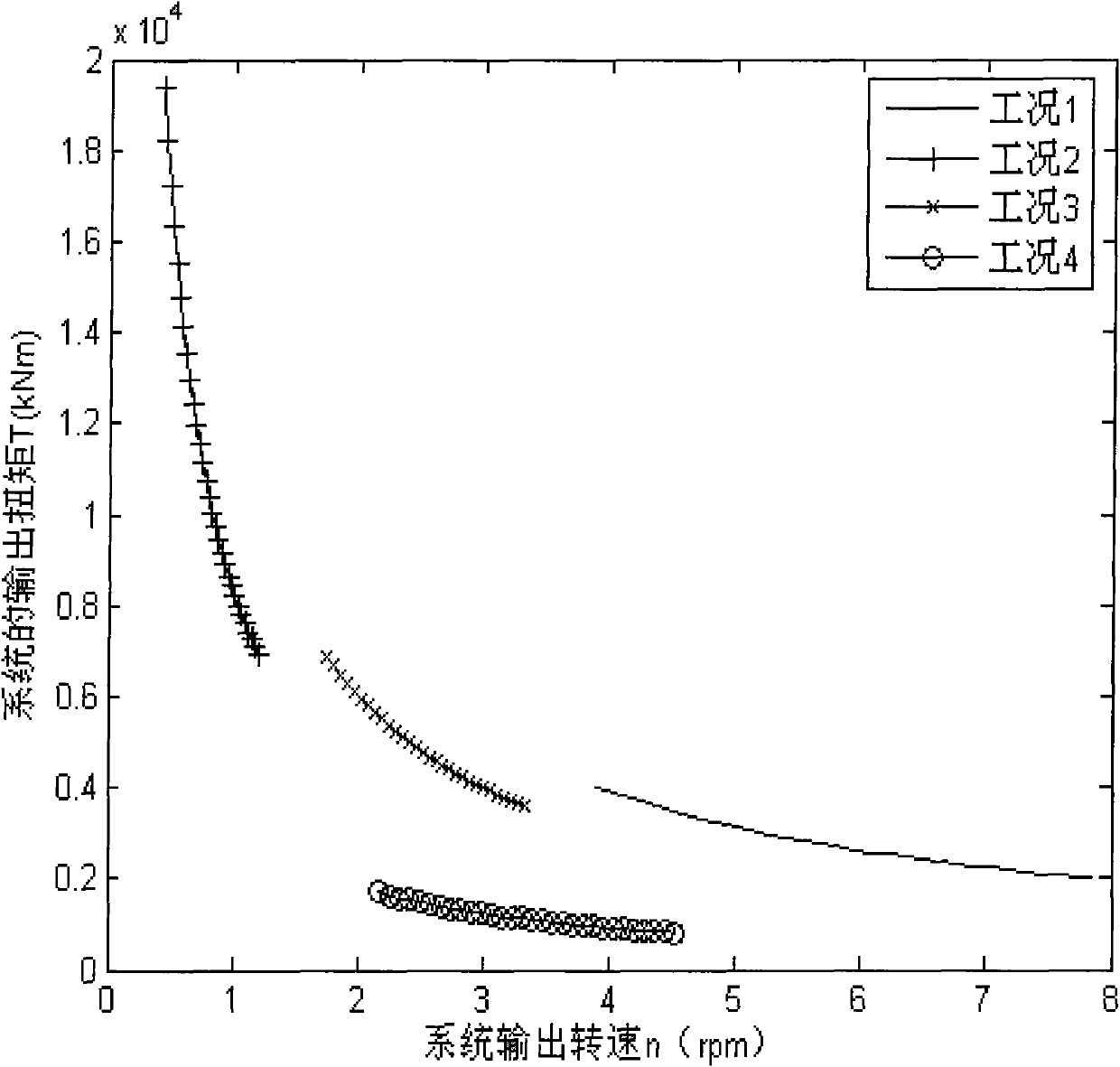

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the transmission mechanism of the present invention, image 3 It is the output characteristic diagram of the present invention, as shown in the figure: the double-drive planetary transmission system of the shield machine in this embodiment includes a power device and a variable speed transmission system, and the power device is a dual-input power device, including power output terminals. The power input assembly I and the power input assembly II of the braking device, in the present embodiment, the power input assembly I 1 is a motor, and a corresponding brake 1a is provided, and the power input assembly II 2 is a motor, and a corresponding brake 2a is provided. The shells are all fixed on the housing 24, and the power output shafts of the two motors (respectively, the power output shaft 8 and the power output shaft 3 in the figure) are sealed and rotated thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com