Growing method of semiconductor material and semiconductor substrate

A growth method and a growth substrate technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unsuitable industrialization, complicated process, and long cycle, so as to save process cost, reduce dislocation density, The effect of improving blocking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for growing a semiconductor material and the specific implementation of the semiconductor substrate provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

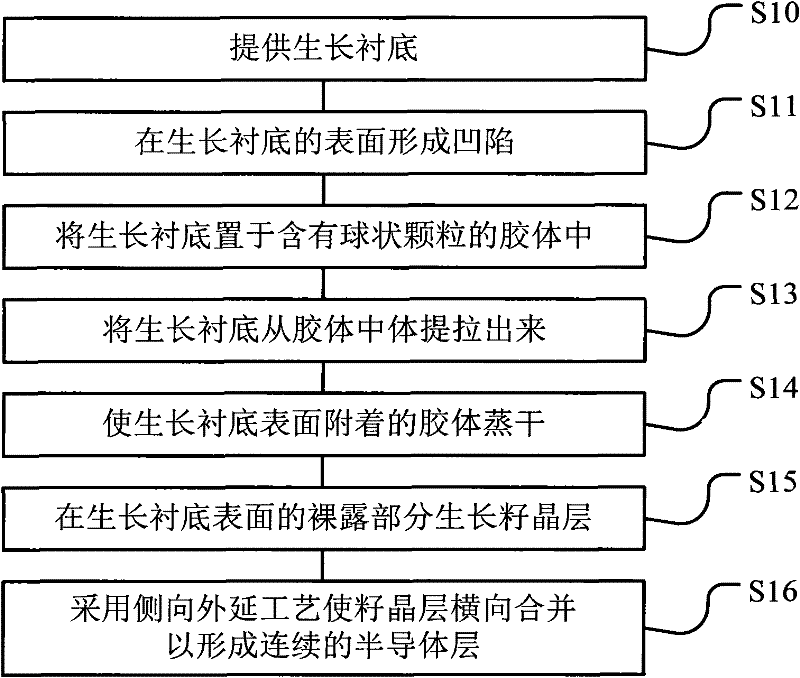

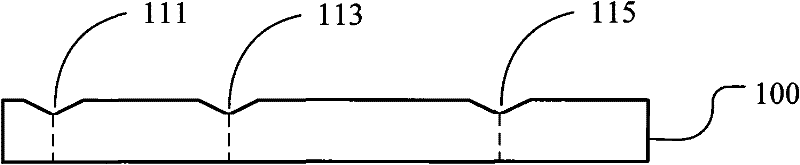

[0027] Firstly, a first specific implementation manner of the semiconductor material growth method of the present invention is given in conjunction with the accompanying drawings. attached figure 1 Shown is a schematic diagram of the implementation steps of this specific embodiment, including the following steps: step S10, providing a growth substrate; step S11, forming a depression on the surface of the growth substrate; step S12, placing the growth substrate on a colloid containing spherical particles middle; Step S13, pulling the growth substrate out of the colloid; Step S14, evaporating the colloid attached to the surface of the growth substrate; Step S15, growing a seed layer on the exposed part of the growth substrate surface; Step S16, Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com