Perfusion method and device of protection glue for chip insulation

A protective glue and chip technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems affecting the long-term stability of protective glue, not taken into account, etc., to improve surface breakdown voltage, good insulation effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

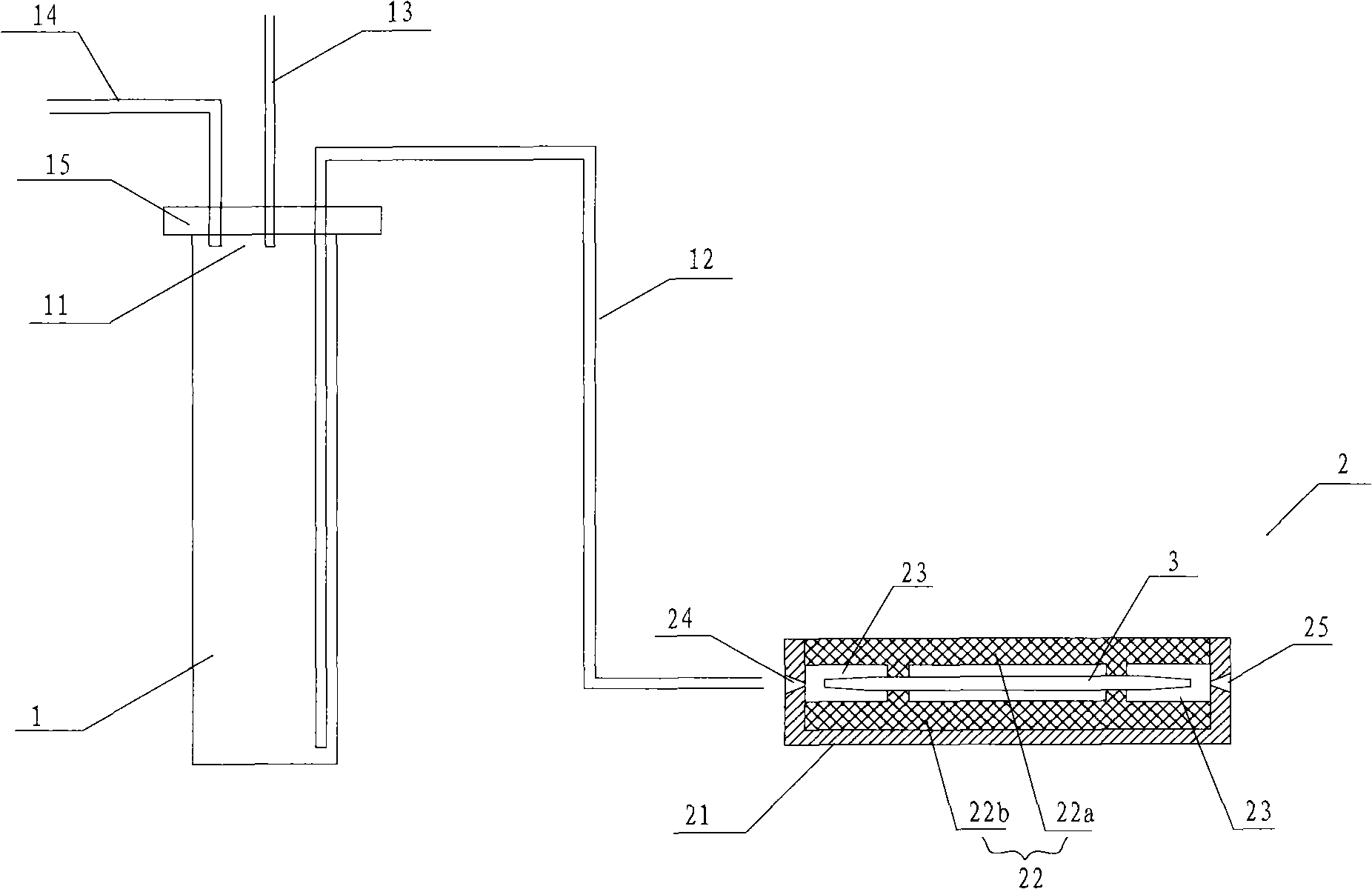

[0032] The present invention will be described in detail below with reference to the drawings and specific embodiments.

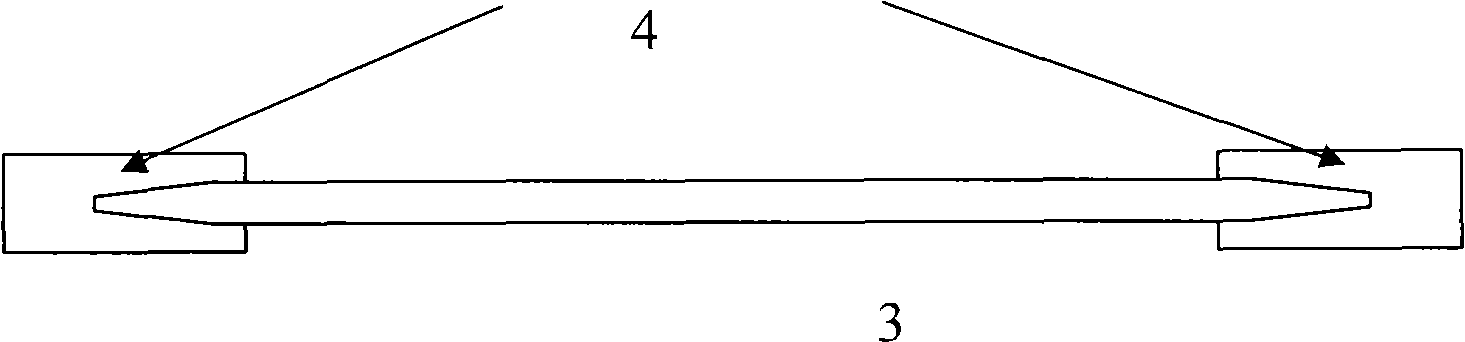

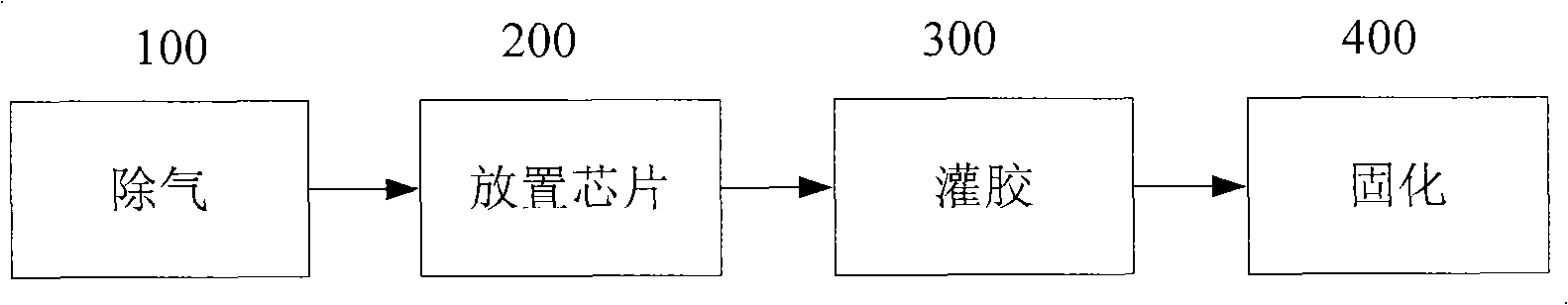

[0033] figure 2 It is a schematic flow chart of the protective glue pouring method of the present invention. image 3 It is a schematic diagram of the structure of the protective glue pouring device of the present invention.

[0034] Such as figure 2 As shown, the protective glue pouring method for chip insulation of the present invention includes: a degassing step 100, a chip placement step 200, a glue filling step 300, and a curing step 400.

[0035] In the degassing step 100, first pour the protective glue into figure 2 After the airtight container 1 is shown, the airtight container is evacuated and kept under vacuum for a period of time, so that the air bubbles in the protective glue are discharged due to the negative pressure of the airtight container.

[0036] The protective rubber added is preferably silicone rubber, such as dimethyl silicone rubber, meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com