Iron-based mixed powder and iron powder sintered body for powder metallurgy

A mixed powder and powder metallurgy technology, applied in the field of iron-based mixed powder and iron powder sintered body for powder metallurgy, can solve the problems of environmental pollution and strength reduction, and achieve improved tool life, strength will not decrease, good cutting sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0083] To the iron powder with the composition shown in Table 1, 0.8% by mass of graphite powder, 2.0% by mass of Cu powder, a predetermined amount of oxide powder shown in Table 2 (refer to Table 3), and 0.75% by mass of iron powder were added. Zinc fatty acid was used as a lubricant and mixed for 60 minutes using a V-type mixer to prepare iron-based mixed powder for powder metallurgy. Next, the iron-based mixed powder for powder metallurgy is molded to form a ring-shaped compact with an outer diameter of 64 mm, an inner diameter of 24 mm, and a height of 20 mm. The compacted powder was sintered for 30 minutes under the conditions. Adjust the forming pressure during forming so that the density of the sintered body reaches 6.8~6.85g / cm 3 .

[0084] It should be noted that the melting point of the oxides in Table 2 uses state diagrams, and the viscosity of the liquid phase mainly uses literature values.

[0085] [Table 1]

[0086] C (mass%)

Si (mass%)

Mn (m...

no. 2 Embodiment

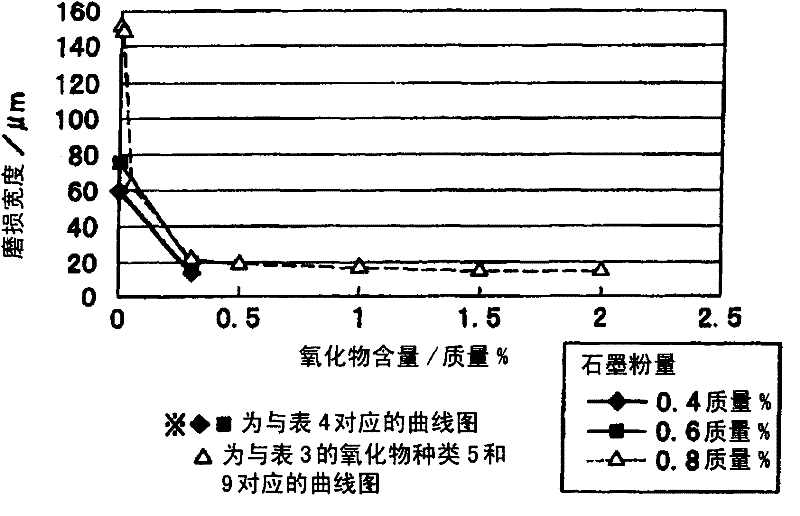

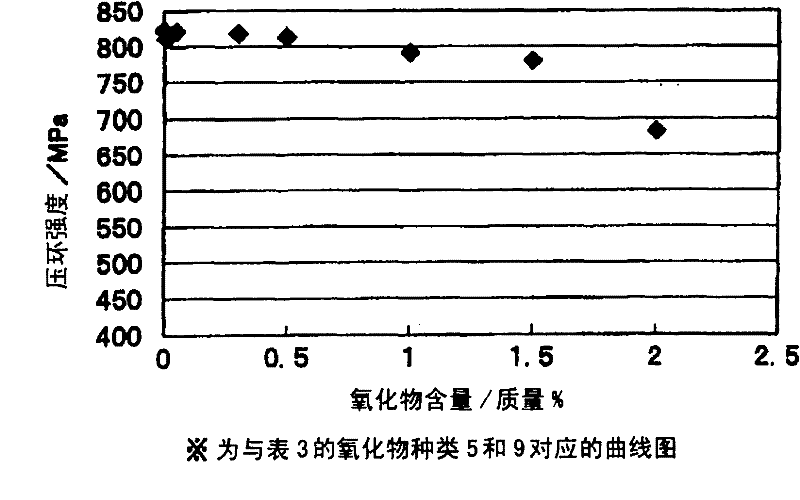

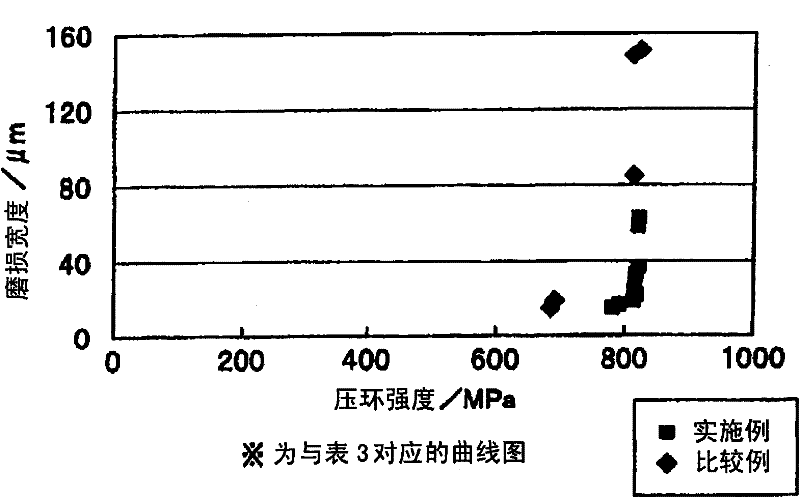

[0105] Next, in order to investigate the influence of the content of graphite powder, the addition amount of graphite powder (the addition amount of C) was set to 0.4 mass%, 0.6 mass% or 0.8 mass%, and the addition amount of the composite oxide was set to no addition or 0.3 mass% to test. In addition, the preparation method of the sintered body and the evaluation method of strength and machinability are the same as those of the above-mentioned first embodiment. However, in the second example, the pass judgment criteria of strength and machinability are not specifically defined for the test of investigating the influence of the graphite powder content.

[0106] These test results are shown in Table 4 (Test Nos. 1 to 6).

[0107] [Table 4]

[0108]

[0109] * The type of oxide corresponds to No. 5 or 9 in Table 2.

[0110] As shown in Table 4, when the addition amount of the graphite powder was any one of 0.4 mass%, 0.6 mass%, and 0.8 mass%, the machinability was improved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com