High-strength steel sheet

A high-strength steel plate and width technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problem of reduced processability of steel materials, and achieve the effect of cost reduction and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

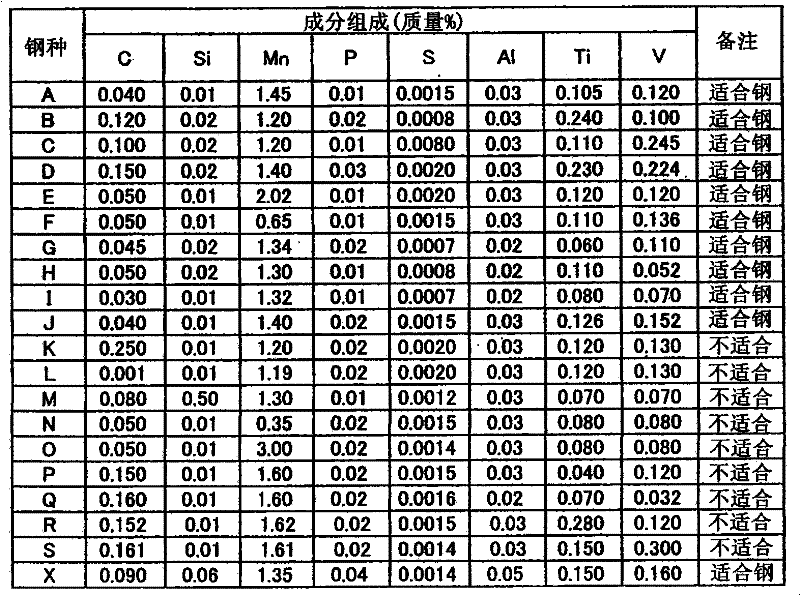

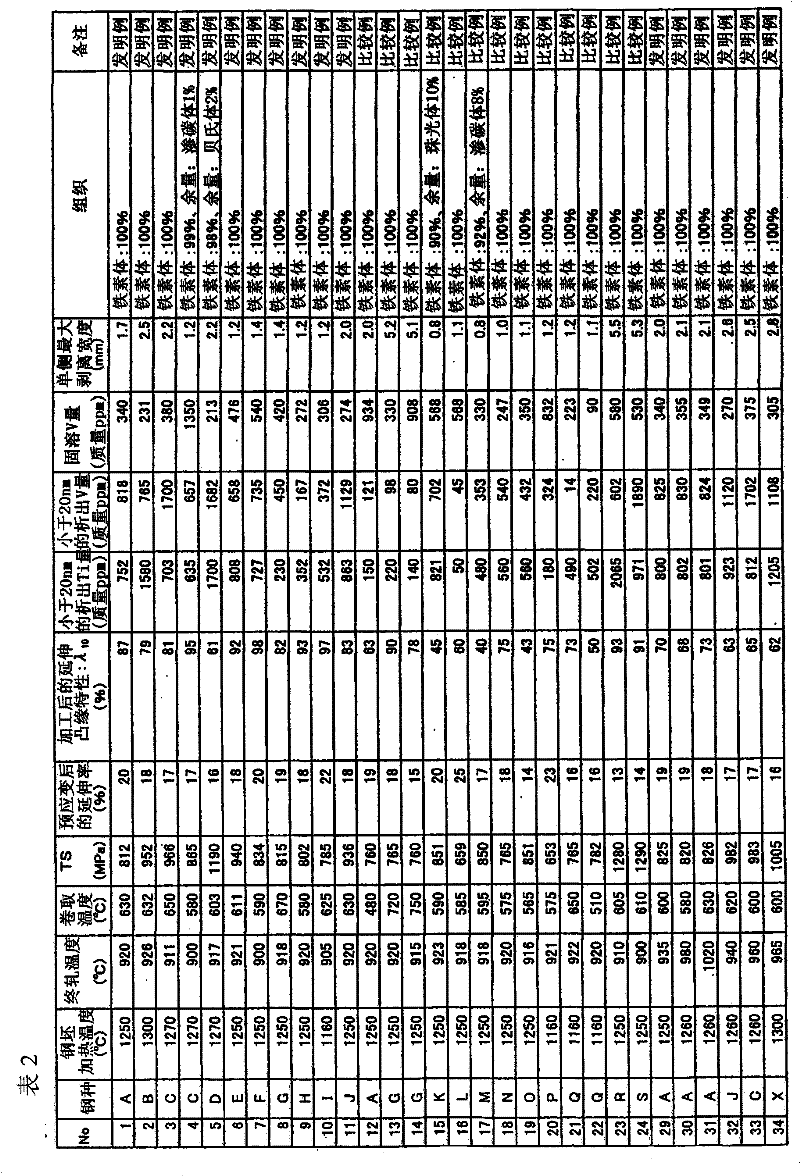

[0112] Steels having the compositions shown in Table 1 were smelted in a converter, and billets were produced by continuous casting. Next, these steel slabs were heated, hot-rolled, and coiled under the conditions shown in Table 2 to produce hot-rolled steel sheets with a thickness of 2.0 mm.

[0113] Table 1

[0114]

[0115] The microstructure of the obtained hot-rolled steel sheet was analyzed by the method shown below to determine the amount of Ti and V contained in precipitates smaller than 20 nm, and the amount of solid solution V. In addition, the tensile strength: TS, and stretch flange properties after processing: λ were obtained by the methods shown below 10 And corrosion resistance after painting: the maximum peeling width on one side of SDT, and evaluate it.

[0116] Microstructural Analysis

[0117] The hot-rolled steel sheet obtained above was cut into an appropriate size, and about 0.2 g was dissolved at 20 mA / cm 2 constant current electrolysis.

[0118]...

Embodiment 2

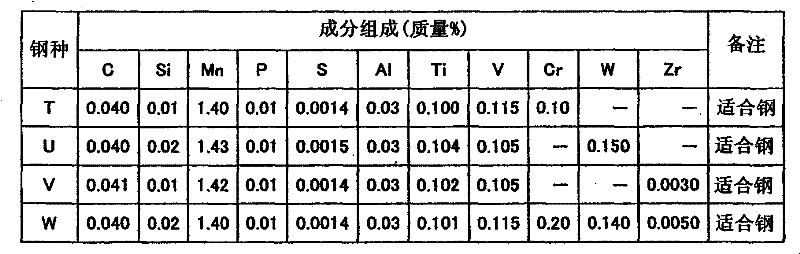

[0134] Steels having the compositions shown in Table 3 were smelted in a converter, and billets were produced by continuous casting. Next, under the conditions shown in Table 4, these steel slabs were heated, hot rolled, and coiled to produce hot-rolled steel sheets with a thickness of 2.0 mm.

[0135] table 3

[0136]

[0137] For the obtained hot-rolled steel sheet, the microstructure was analyzed by the same method as in Example 1, and the amount of Ti and V contained in precipitates smaller than 20 nm, and the amount of solid solution V were determined. In addition, the tensile strength: TS and the stretch flange property after processing: λ were obtained by the same method as in Example 1 10 And corrosion resistance after painting: the maximum peeling width on one side of SDT, and evaluate it.

[0138] Table 4 shows the results obtained above.

[0139]

[0140] According to Table 4, it can be seen that the TS of the example of the present invention is more than 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com