Environment-friendly production process of high-protein feeding meat meal

A production process and environment-friendly technology, applied in application, animal feed, animal feed, etc., can solve the problems of animal protein, fat shortage, low protein content of meat powder, and extensive processing methods, so as to save feed cost and increase protein Digestibility, clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment:

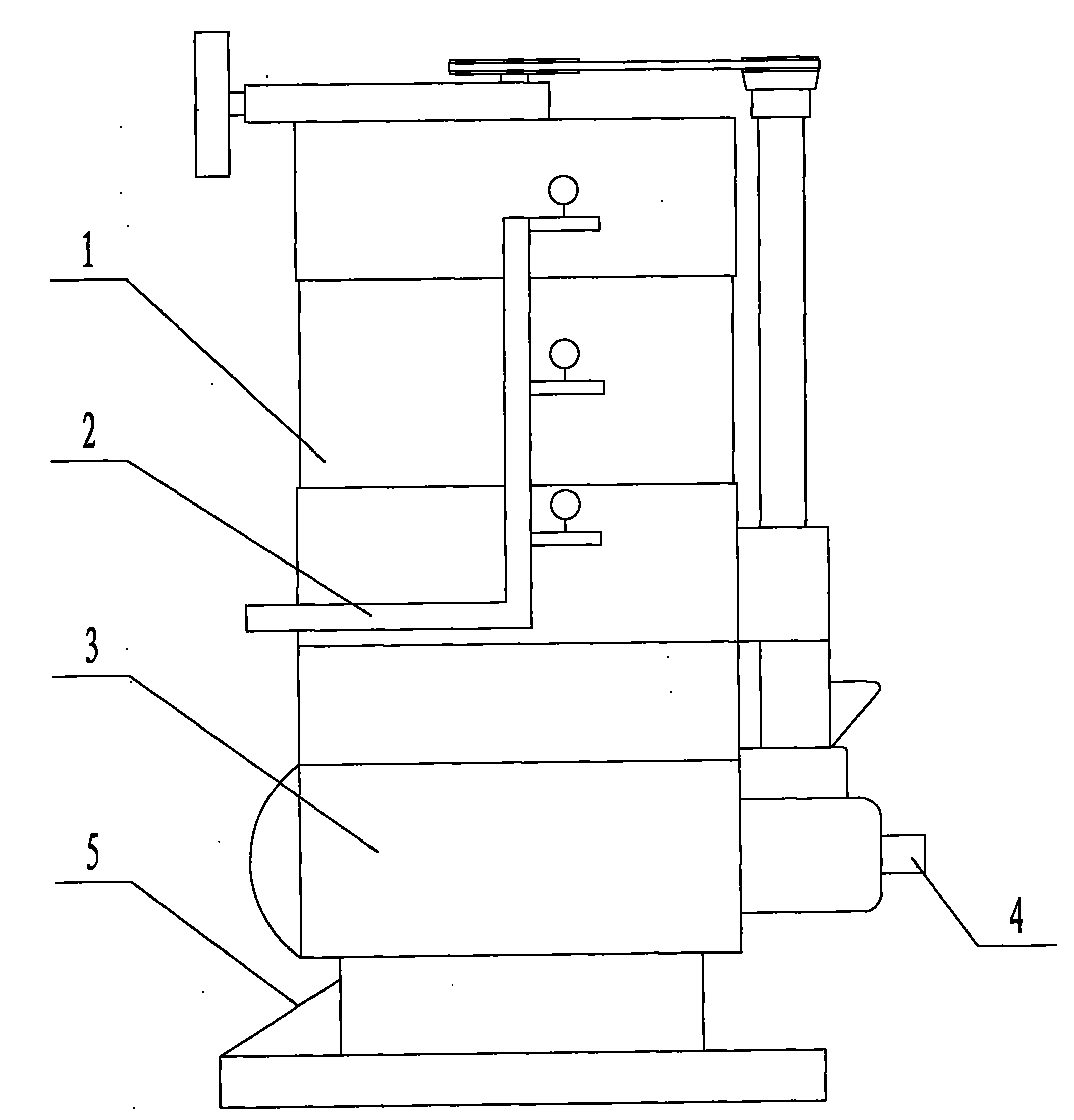

[0013] Such as figure 1 As shown, the thermal spray furnace includes a three-stage heating and pressurizing furnace 1, a hot steam pipe 2 is connected to the three-stage heating and pressurizing furnace 1, and a screw press 3 is arranged below the heating and pressurizing furnace 1. 3 one end has oil-water outlet 4, and the other end has meat meal outlet 5.

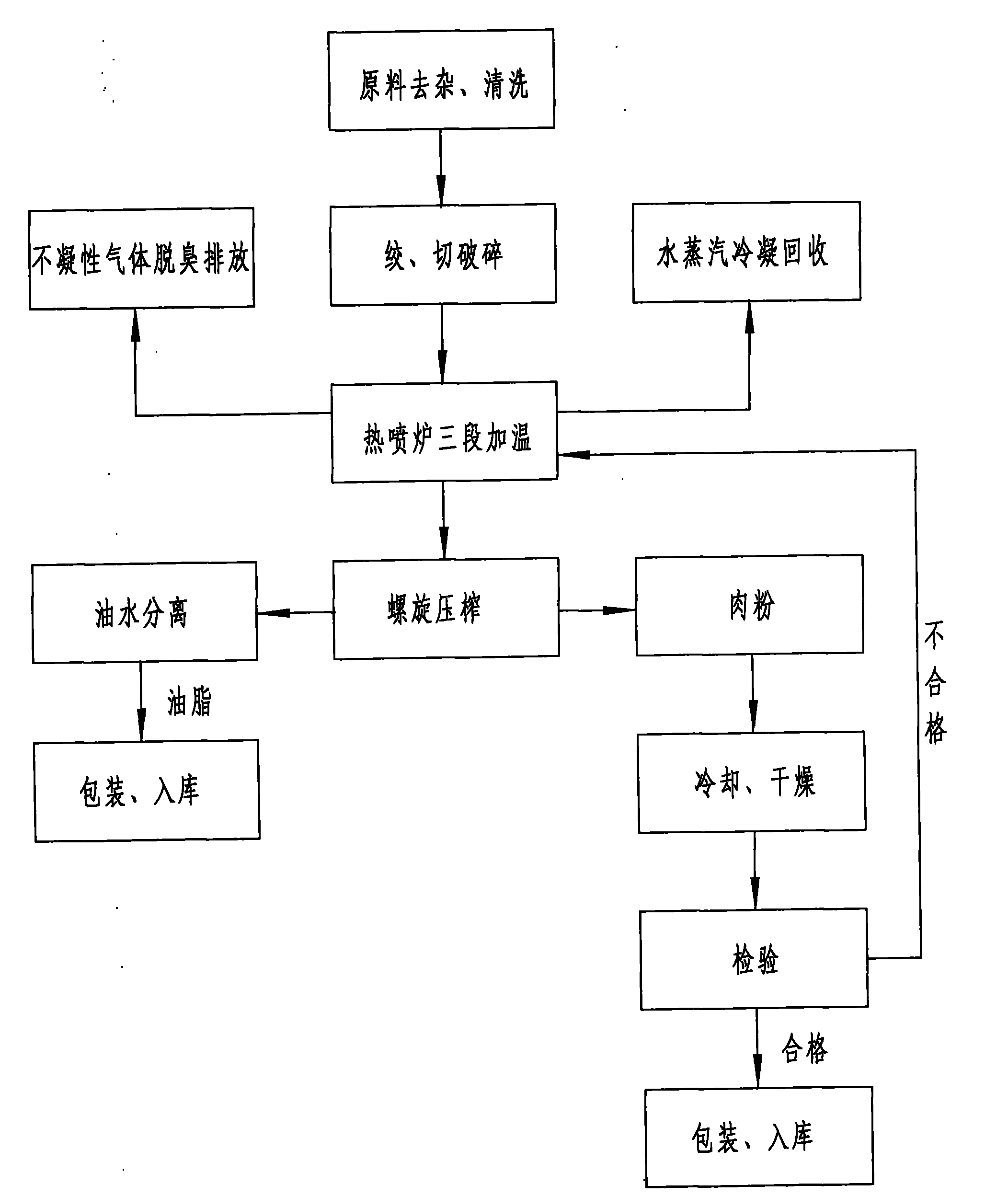

[0014] Such as figure 2 As shown, an environment-friendly production process of high-protein feed meat meal,

[0015] 1) Remove impurities and clean the leftovers after processing livestock and poultry products; the leftovers are mainly animal viscera, fat, minced meat and carcasses that are not suitable for consumption

[0016] 2), shredding and cutting the leftovers after removing impurities and cleaning;

[0017] 3) Enter the thermal spray furnace to heat and pressurize in three stages, the pressure is 0.5-1kg, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com