Device for removing laser paint and application method thereof

An application method and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of decline in defective products, environmental pollution, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

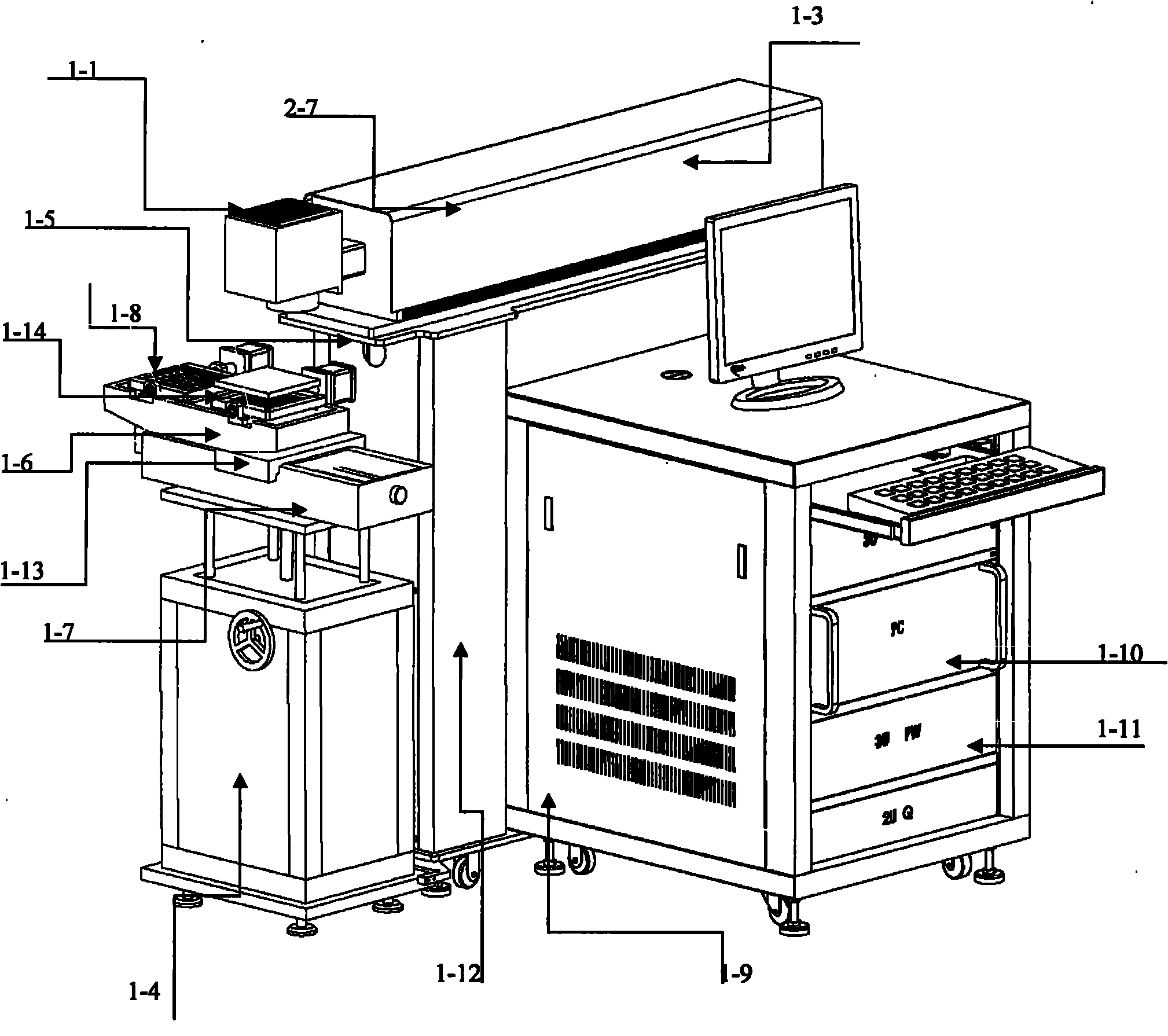

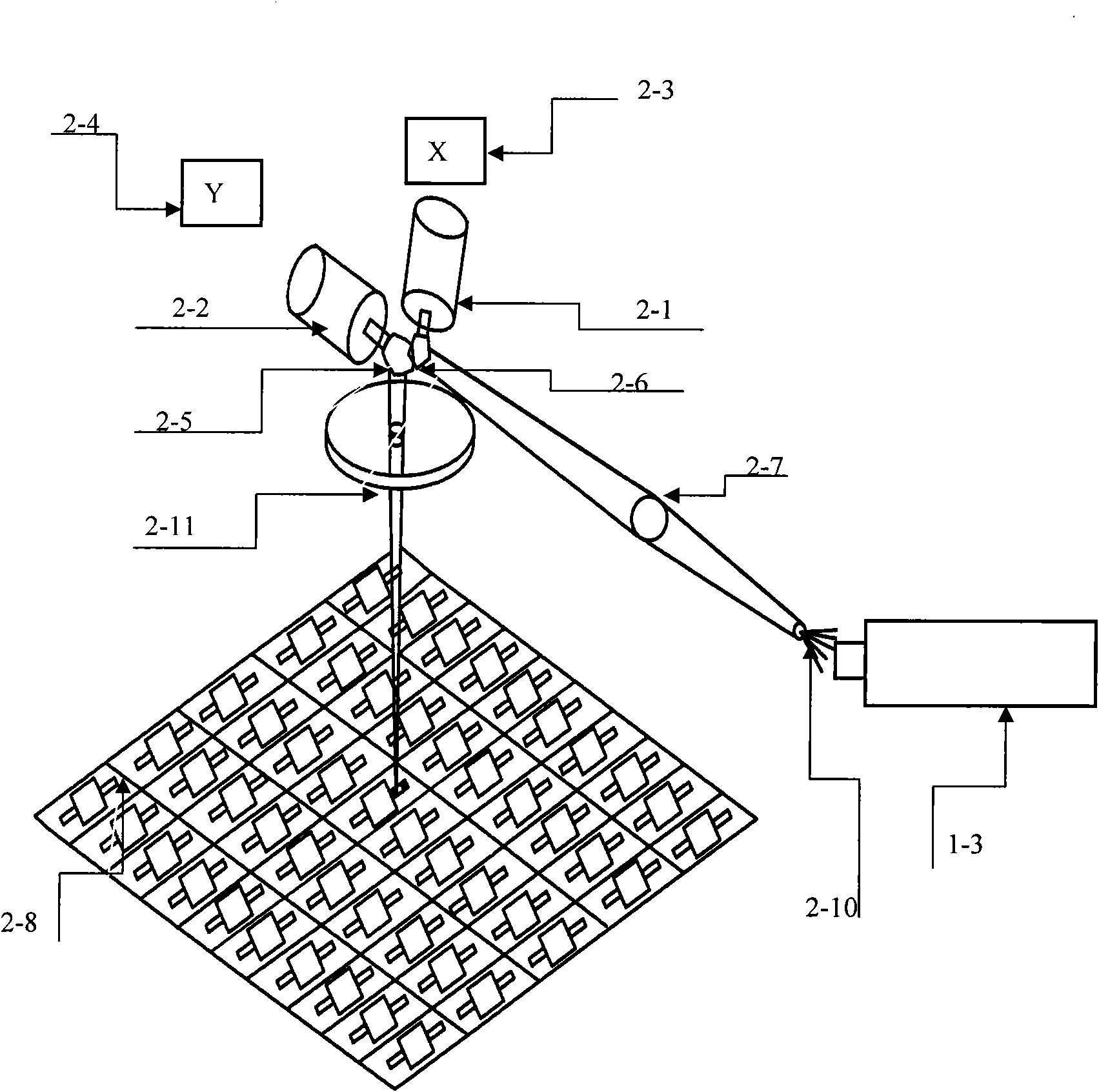

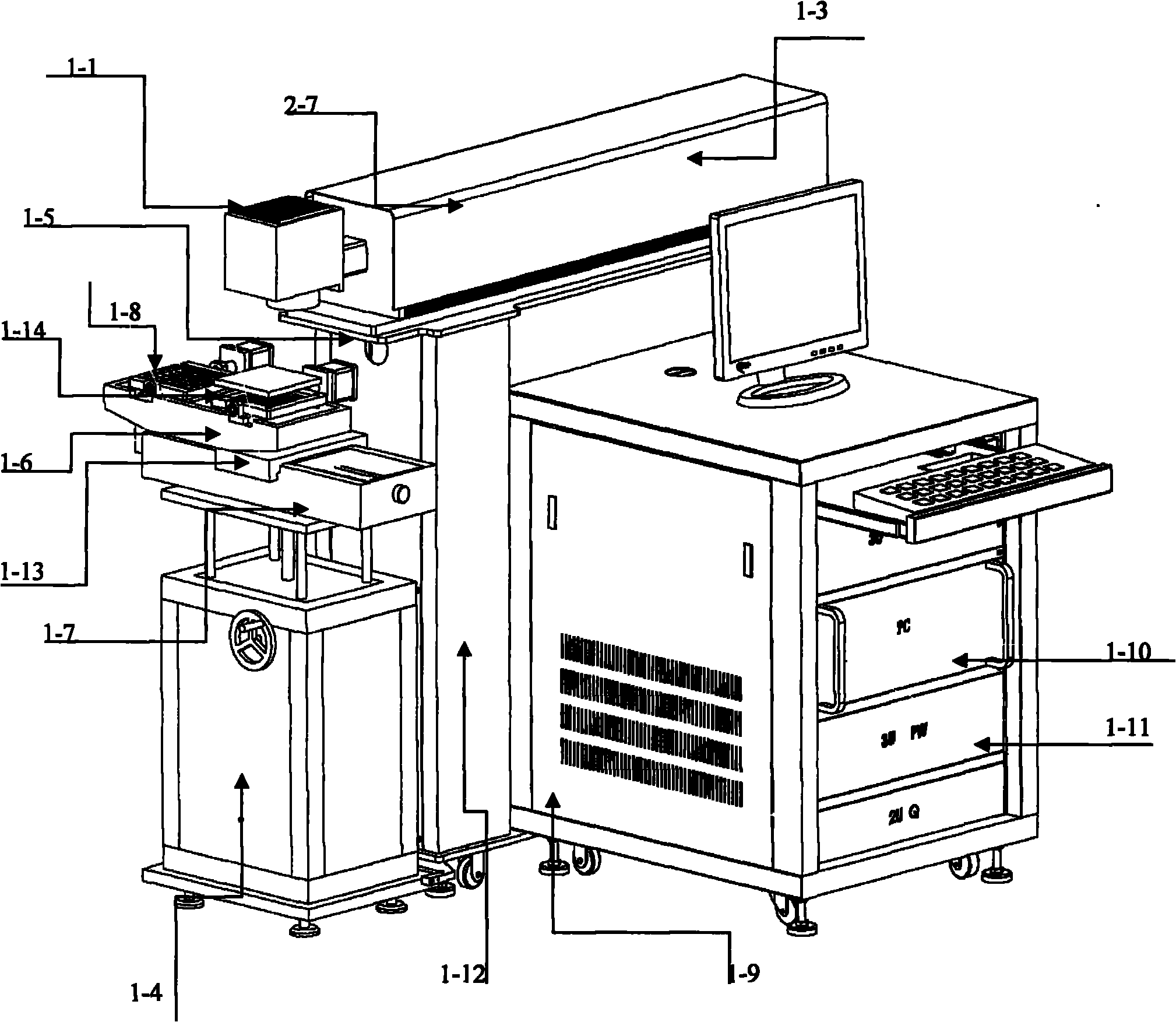

[0047] Example 1, in the embodiment, the laser paint removal operation is performed on the semi-finished solid-state inductors 2-8 of the 06 series. Since the pins of this inductor only have insulating varnish and no black paint, a green laser generator is used to complete the laser removal. paint job.

[0048] First place the solid inductors 2-8 on the fixture tray 1-8 one by one. For the 06 series tray, each tray can hold 80 inductors. After placing the device fixture tray 1-8 on the station turning platform 1-6 In the card slot of the flip frame, it needs to be placed at two stations at the same time at the beginning. When the start button is turned on, the motion platform 1-7 will move slowly under the drive of the controller 1-9, that is, the servo motor controlled by PLC. When the position is 1, the motion platform 1-7 stops. We use the In-Sight 5400 series vision sensor from COGNEX as an independent vision system to deploy in this application environment, and cooperate ...

example 2

[0049] Example 2, in the embodiment, the laser paint removal operation is performed on semi-finished solid-state inductors 2-8 with specifications of 10 (10mm*10mm) series. Since the pins of this inductor have both insulating varnish and black varnish, red laser Generator to complete the laser paint removal work.

[0050] First place the solid inductors 2-8 on the fixture trays 1-8 one by one. For 10 series trays, 40 inductors can be placed on each tray. After placing them, place the device fixture trays 1-8 on the station turning platform 1-6. In the card slot of the flip frame, it needs to be placed at two stations at the same time at the beginning. When the start button is turned on, the translation platform moves slowly under the drive of the servo mechanism controlled by PLC1-9. When it reaches the position of work 1, the movement platform 1-7 stops, we use the In-Sight 5400 series vision sensor from COGNEX as an independent vision system to deploy in this application env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com