Gallium-lanthanum silicate serial crystal high-temperature zero-temperature compensating cut type and application

A gallium lanthanum silicate, zero temperature technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of zero temperature compensation that has not been reported, and achieve high electromechanical coupling coefficient temperature stability and frequency stability High, suitable for a wide range of temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Zero-temperature-compensated cutting of gallium lanthanum tantalate crystal

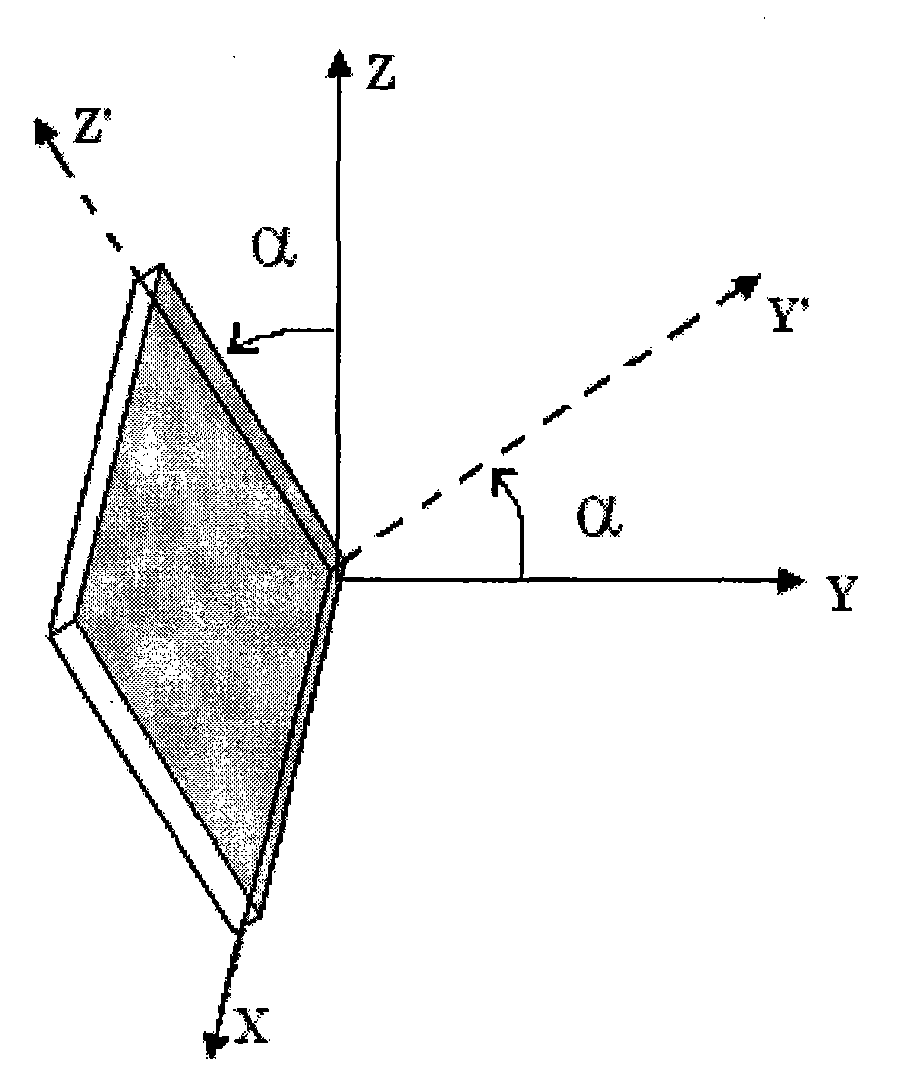

[0035] 1. If figure 1 Shown, gallium lanthanum tantalate crystal positive d 11 The direction of is taken as the positive direction of X, and the Y and Z directions are determined according to the right-hand spiral rule. YXltw(α) means that the thickness direction is Y, the length direction is X, and the length direction, that is, the X direction is rotated by the angle α according to the right-hand spiral rule, α=-20°, and the LGT cut sample YXltw(-20°) is processed according to the above method , sample size is 1.5×9.0×9.0mm 3 .

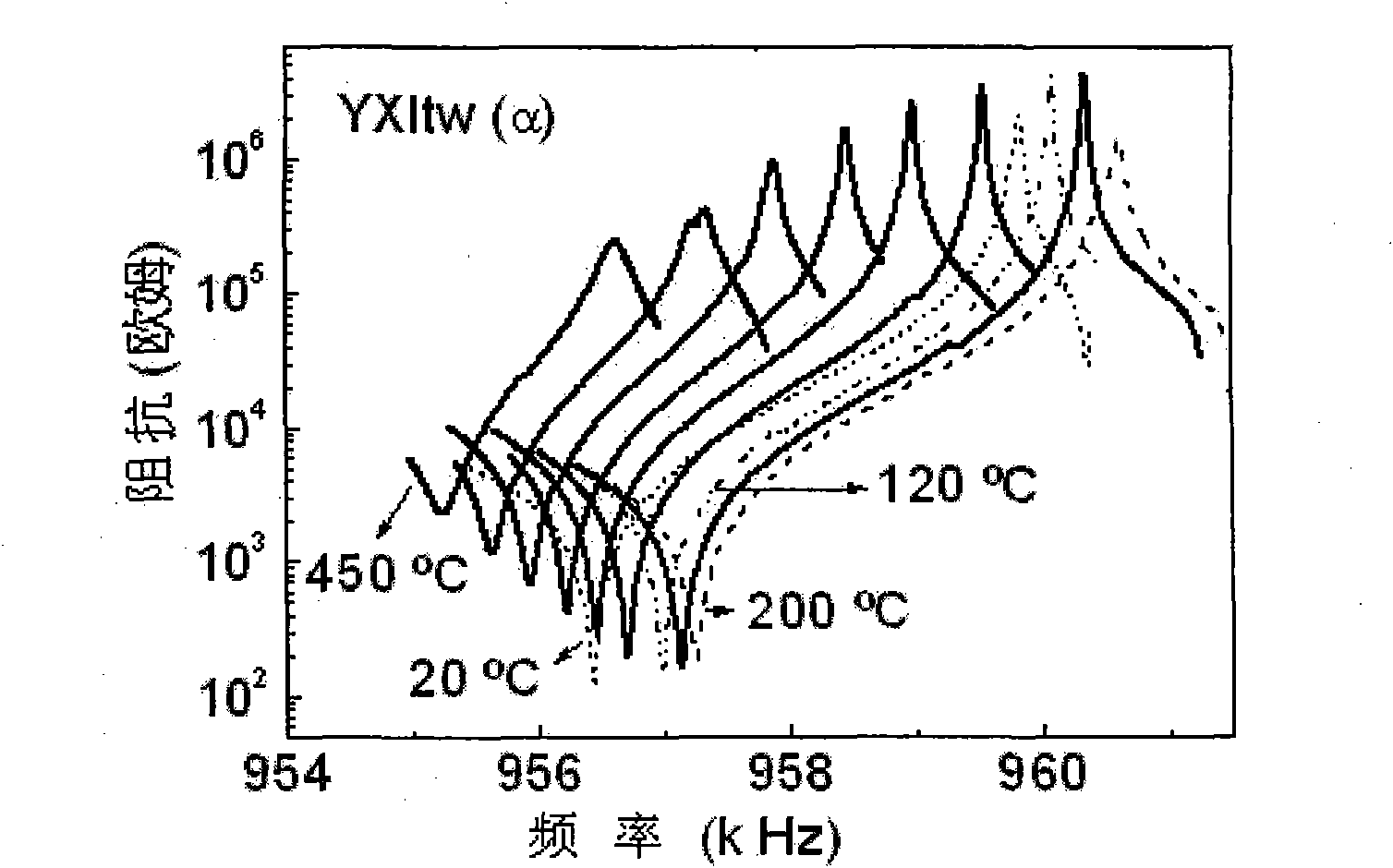

[0036] 2. Platinum electrodes are plated on the thickness direction of LGT-cut samples. The electrode thickness is 200nm. Place the platinum-plated sample devices in a program-controlled heating furnace to test the frequency and temperature characteristics to eliminate electromagnetic interference. The temperature range is set to: 20-500°C . Use the ...

Embodiment 2

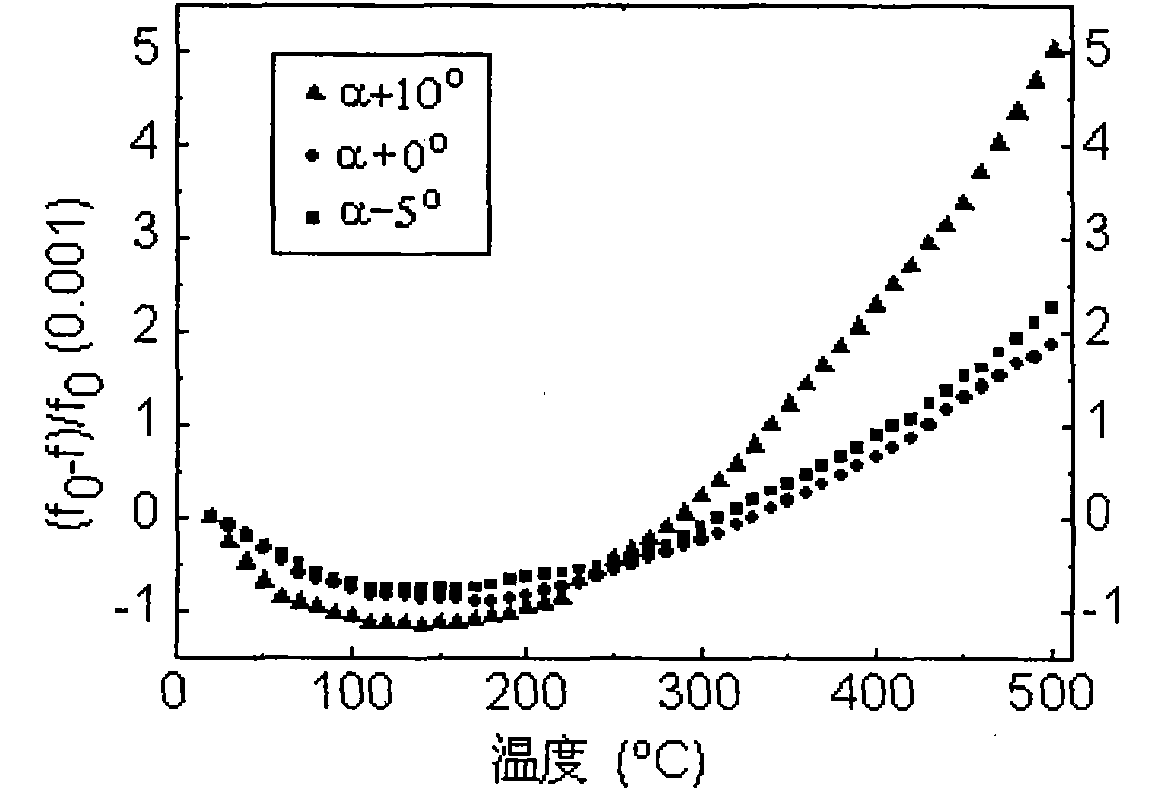

[0039] As in Example 1, the difference is that the YXltw (-25°) cut type is also used, and the sample size is 0.6×12.0×12.0mm 3 The frequency of the frequency device is measured in the range of 20-500 ℃, and the frequency change with temperature is measured, and the temperature stability of the frequency device is within 8ppm / ℃, see image 3 shown.

Embodiment 3

[0041] As in Example 1, the difference is that the sample angle is processed as YXltw (-10°), and the sample size is 0.6×9.0×9.0mm 3 The frequency of the frequency device is measured in the range of 20-500°C, and the frequency change with temperature is measured, and the temperature stability of the frequency device is within 15ppm / °C, see image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com