Premixed partial oxidation syngas generation and gas turbine system

A gas turbine, oxygen technology, applied in gas turbine installations, turbine/propulsion fuel delivery systems, charging systems, etc., can solve problems such as difficult to combine combustion systems, large and complex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

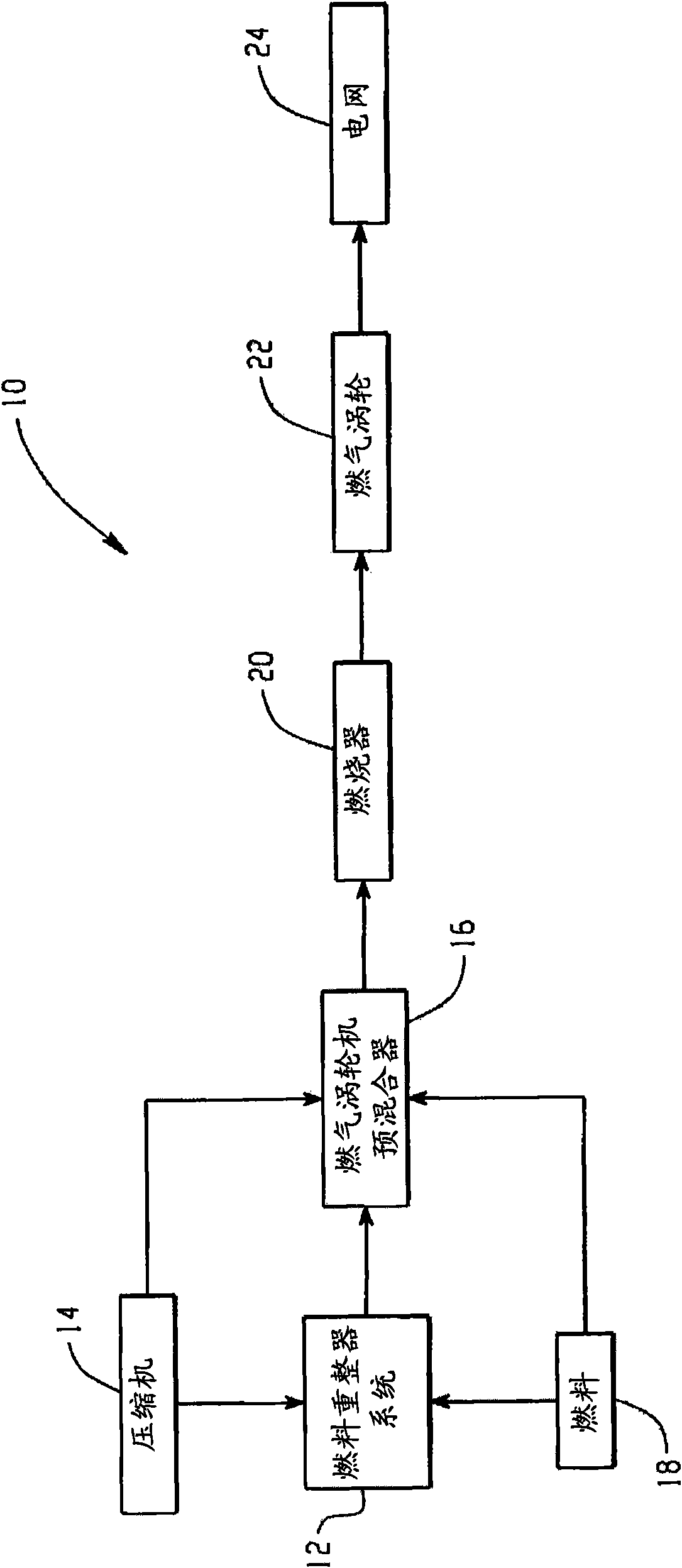

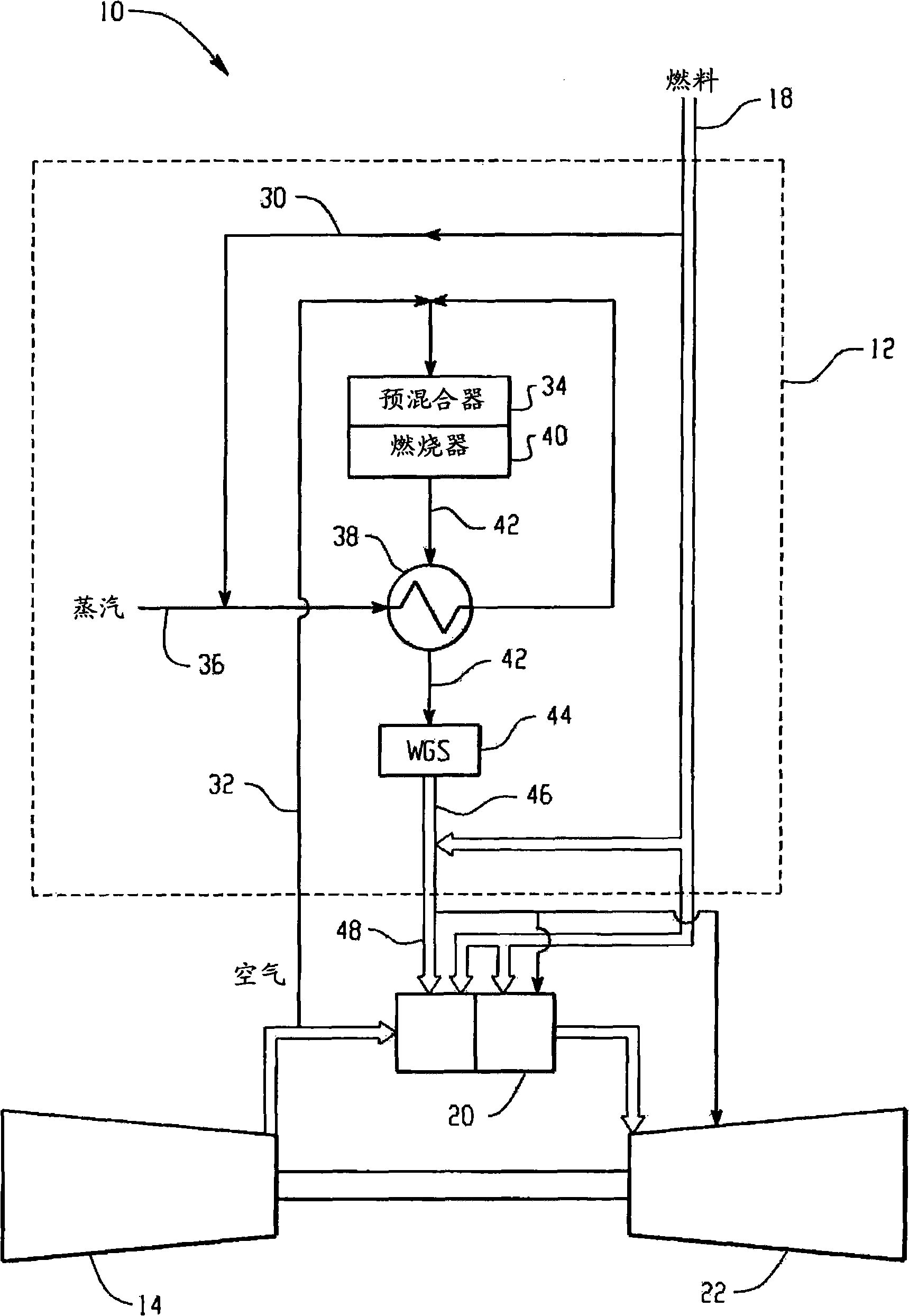

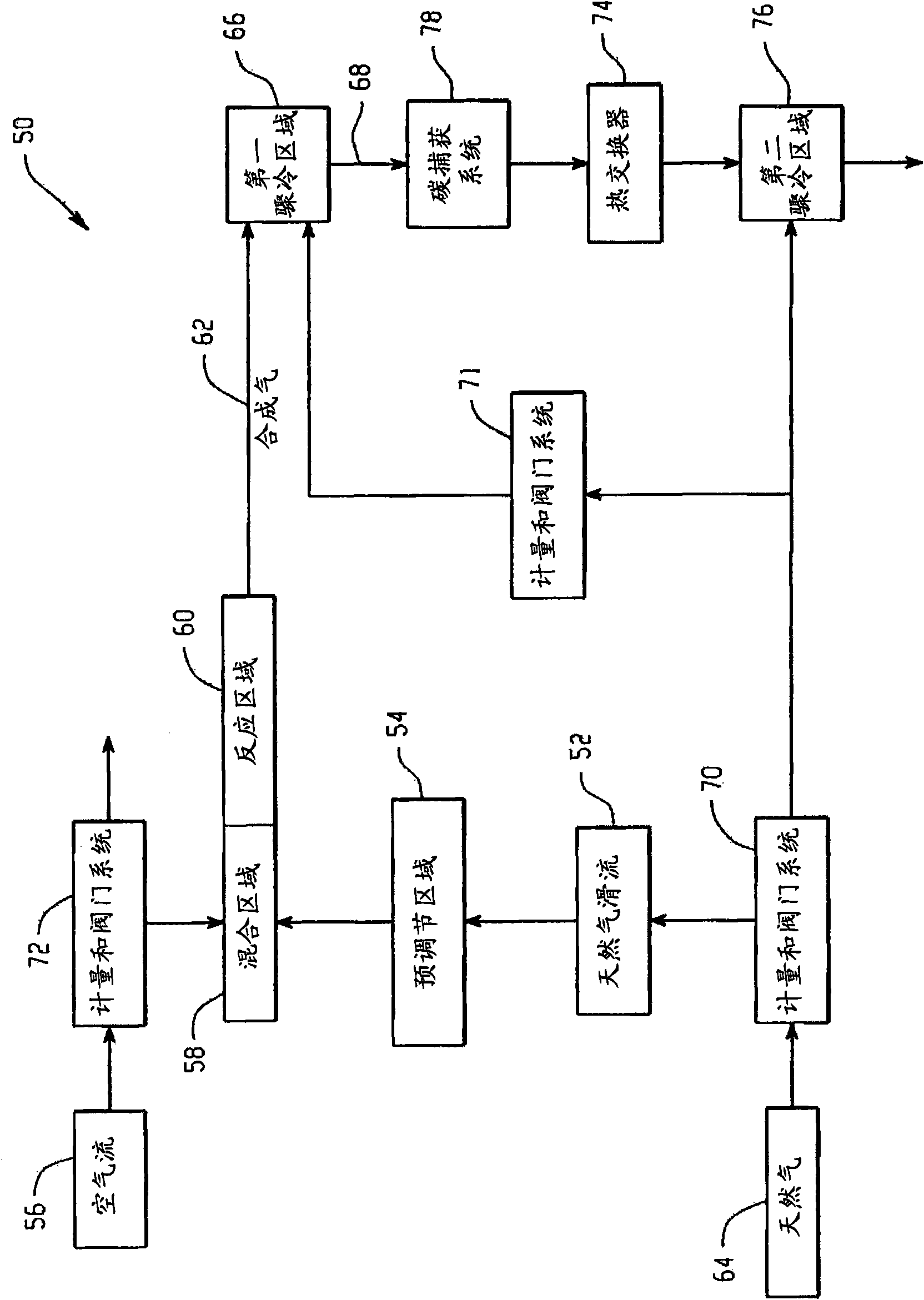

[0157] As described in detail below, disclosed embodiments of the present invention provide a gas turbine system incorporating a fuel reformer system. The systems and techniques described herein are used to enhance the power output and efficiency of gas turbine systems, such as staged gas turbine systems and reheat gas turbine systems. Reformer systems utilized in gas turbine systems are configured to provide mixing and reaction of a fuel slip stream with an oxygen slip stream to increase hydrogen concentration through premixed partial oxidation combustion. The introduction of hydrogen into the fuel allows for lowering of the lean flameout point and enables reduction of combustion dynamics to the gas turbine system. As used herein, the term "combustion dynamics" refers to fluctuations in oxygen pressure, temperature, heat release, and unsteady flow oscillations that affect the operation of engines, including gas turbines. Additionally, the term "lean flameout point" as used h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com