Combined pulse formation network and method

A technology of combining pulses and pulses, which is applied in the direction of electrical components and electric energy storage systems, etc., can solve the problems of reducing the service life of power supplies, ablation of electronic devices, wasting electric energy, etc., and achieve the effect of improving energy utilization efficiency and life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

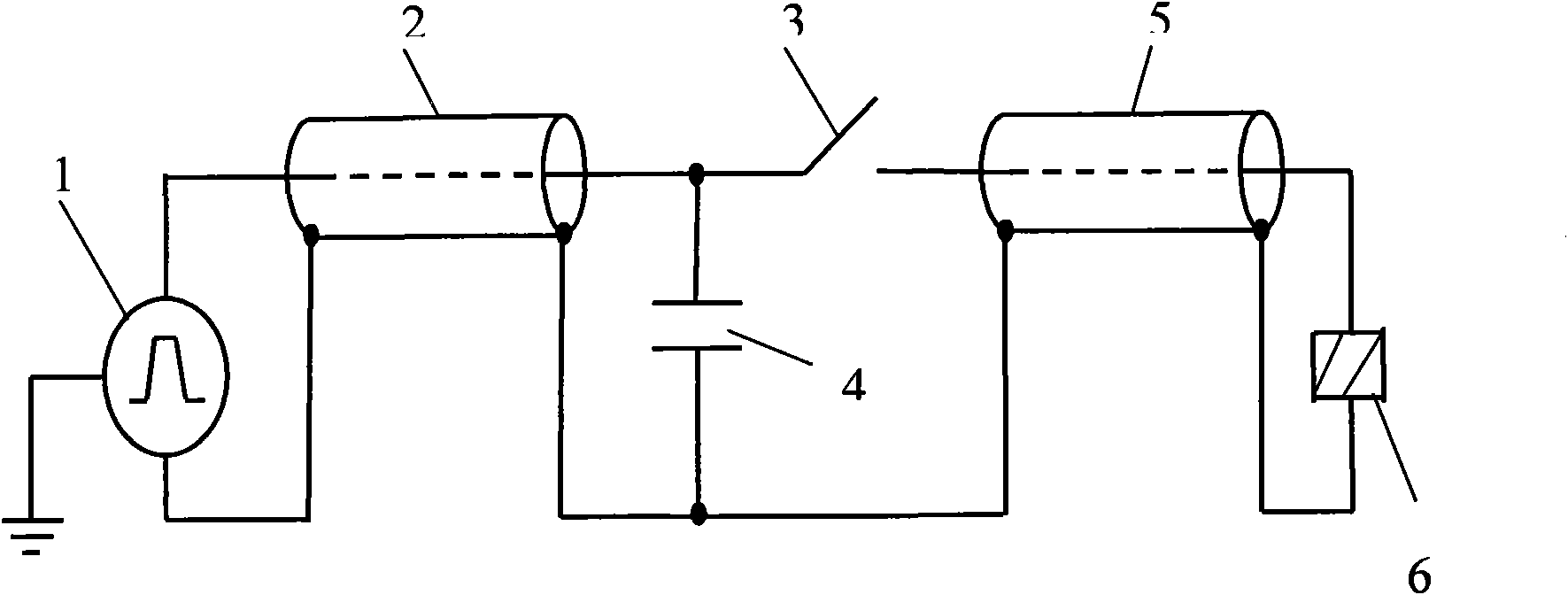

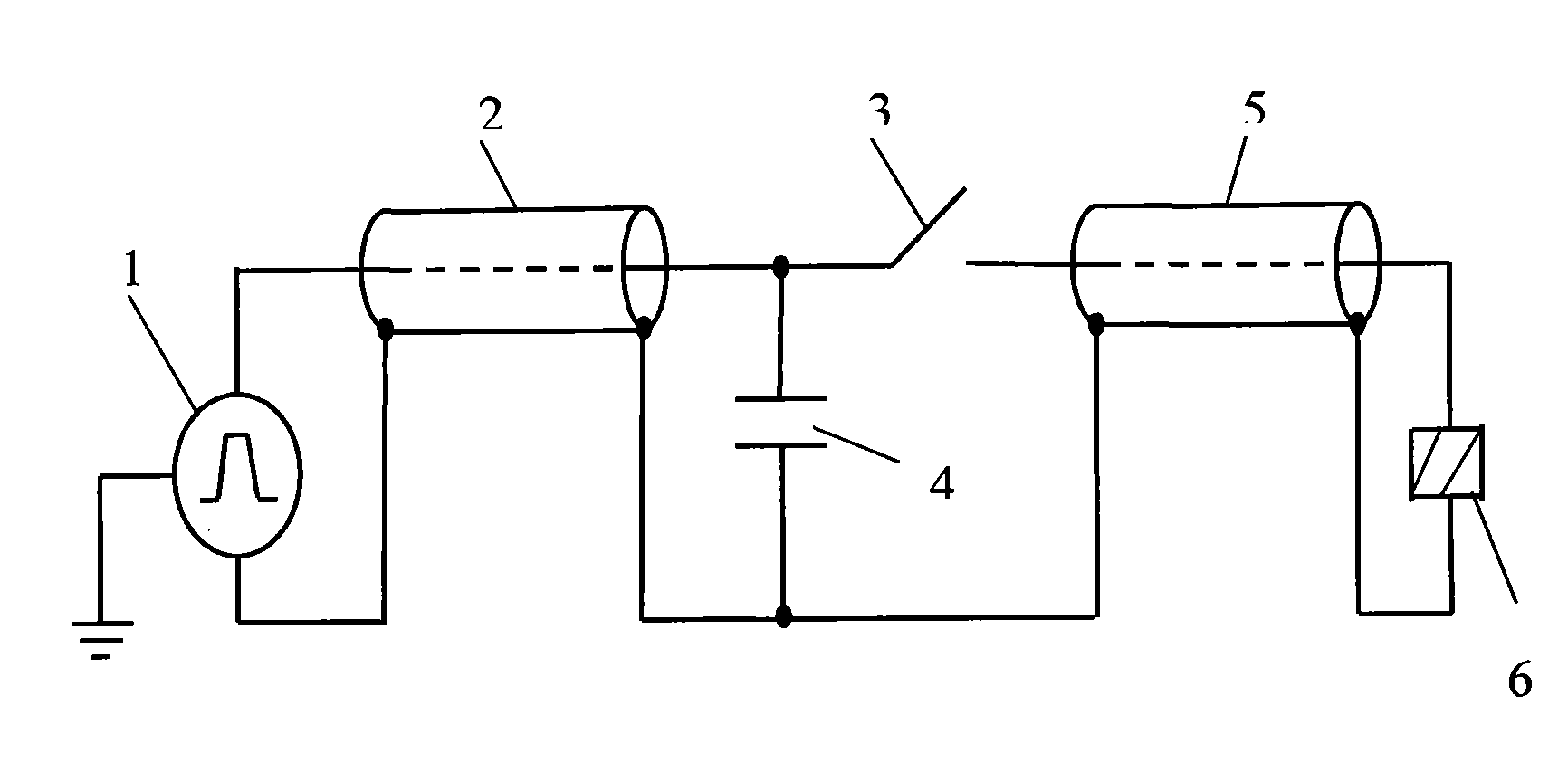

[0014] exist figure 1 Among them, the output end of the primary high-voltage pulse charging power supply 1 is connected to the input end of the pulse forming line 2; the output end of the pulse forming line 2 is respectively connected with the high voltage end of the energy storage capacitor 4 and the anode of the switch 3, and the low voltage of the energy storage capacitor 4 terminal is reliably grounded, the cathode of the switch 3 is connected to the input end of the pulse transmission line 5; the output end of the pulse transmission line 5 is connected to the working electrode of the load 6.

[0015] The pulse forming line 2 in the combined pulse forming network of the present invention can adopt a coaxial cable, a flat pulse forming line, an artificial forming line or any other pulse forming system; the energy storage capacitor 3 is a low-inductance, high-voltage ceramic that can be repeatedly charged and discharged capacitor or other capacitors formed; the switch 4 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com