Thermoplastic polyurethane tape

A thermoplastic polyurethane and isocyanate-based technology, applied in the field of thermoplastic polyurethane belts, can solve the problems of low strength, undisclosed copolymerization ratio, and unrecorded elongation recovery, etc., and achieve good recovery and small residual strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

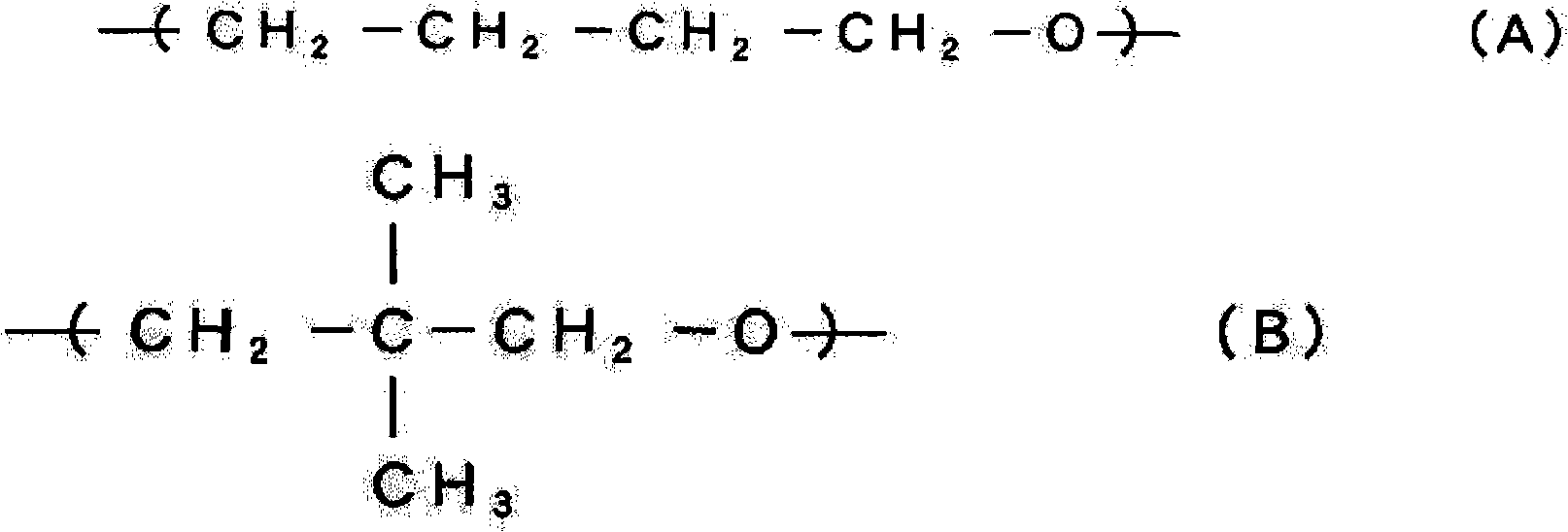

[0069] As the polyalkylene ether glycol (ii), PTXG1800 manufactured by ASAHI KASEI FIBERS CORPORATION was used. Copolymerization composition M of PTXG1800 B / (M A +M B ) is 0.1. 1400 g of PTXG and 389.4 g of 4,4'-diphenylmethane diisocyanate were reacted under nitrogen flow at 80° C. for 180 minutes while stirring to obtain a polyurethane prepolymer having isocyanate groups at both ends. Next, this prepolymer was rapidly cooled to 25° C., and 35 g of 1,4-butanediol was added to the prepolymer, followed by stirring for 30 minutes. Polyurethane with a viscosity of 117000 mPa·s (25° C.) was obtained.

[0070] This polyurethane was mixed with 9 g of AO-60 manufactured by ADEKA CORPORATION as an antioxidant and 9 g of LA-36 manufactured by ADEKA CORPORATION as an anti-yellowing agent, and discharged on a Teflon (registered trademark) tray.

[0071] The polyurethane was annealed in a hot-air oven at 130° C. for 3 hours in a state where the polyurethane was loaded on a Teflon (r...

Embodiment 2

[0078]The polyurethane resin powder obtained in Example 1 was melt-extruded and shaped with a twin-screw extruder KZW15TW-45HG manufactured by TECHNOVEL CORPORATION. At a die temperature of 200° C., it was extruded into a film form from a T-die with a width of 150 mm and a lip width of 1.0 mm at an injection rate of 12.4 g / min. It was wound up with a metal roll cooled to 15° C. at a roll speed of 0.5 m / min to obtain a film with a thickness of 250 μm.

[0079] This film was slit and processed to obtain tapes with a width of 6 mm. This tape was fixed with a clip in a 4-fold cold-stretched state, and heat-treated in a hot air oven at 70° C. for 30 minutes.

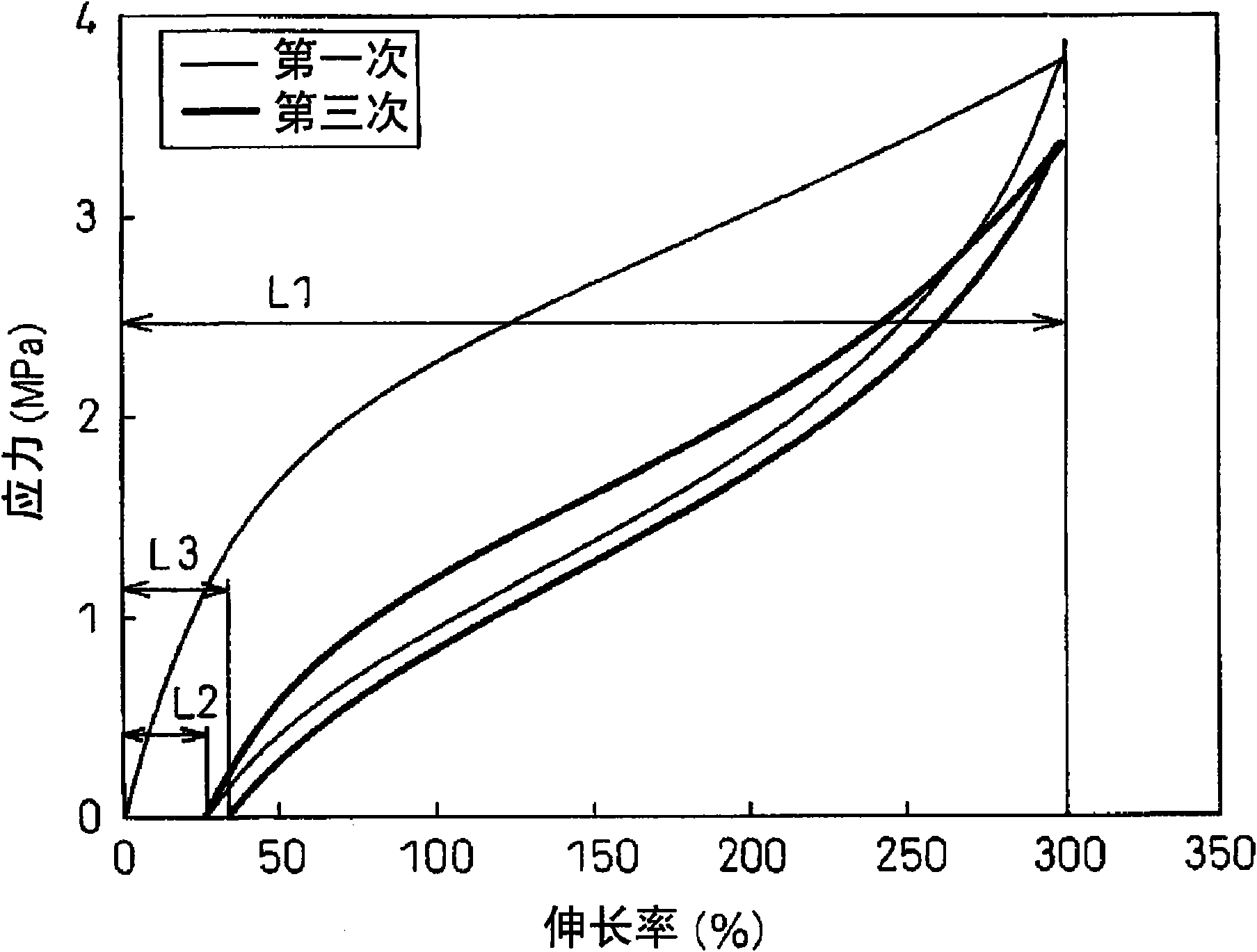

[0080] The tape had a good residual strain of 18% after 300% elongation at 20°C. The stress at 100% elongation of this tape was 4.02 MPa.

Embodiment 3

[0090] The polyurethane resin powder prepared in Example 1 was melt-extruded and shaped with a 50 mmφ single-screw extruder. At a die temperature of 200° C., it was extruded into a strip form at an injection rate of 80 g / min from a slot die having a width of 30 mm and a thickness of 0.2 mm. It is wound on a metal roll cooled to 15° C., and taken up at a roll speed of 30 m / min and a take-up speed of 120 m / min. A tape with a thickness of 110 μm was obtained.

[0091] The tape had a good residual strain of 25% after 300% elongation at 20°C. In addition, the recovery rate after repeating the 300% elongation recovery at -10°C three times was good at 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com