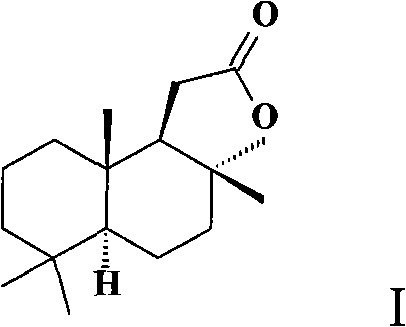

Modified method for preparing sclareolide from sclareol

A technology of sclareolide and sclareolide, applied in the direction of organic chemistry and the like, can solve problems such as residue and loss of sclareolide, and achieve the effects of simple operation, improved total yield, and improved commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get the crystallization mother liquor of sclareolide (provided by a certain factory, take potassium permanganate as the crystallization mother liquor of the sclareolide synthesized as a catalyst, the content of sclareolide in the crystallization mother liquor is 10wt%~30wt%) 40ml , add 80ml of methanol to get 66mg / ml methanol solution of sclareolactone, add resin HZ-84530g, perform static adsorption at normal temperature (20℃~25℃) and normal pressure (1atm) for 4 hours for pretreatment to remove some impurities . Filter out the liquid and then add resin HZ-81630g, after static adsorption at room temperature (20°C-25°C) and normal pressure (1atm) for 8 hours, use 150ml of borax-NaOH mixed solution with pH value of 9.2, 200ml Wash with deionized water, filter to obtain dry resin, the resin adsorption capacity is 247mg / dry resin g, and the adsorption rate is 92.6%. The adsorbed 30g HZ-816 resin is packed into a column, and the eluent of cyclohexane: butyl acetate: methano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com