Negative photosensitive material and circuit board

A circuit substrate, photosensitivity technology, applied in the direction of circuit substrate materials, photosensitive materials for optomechanical equipment, printed circuit components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

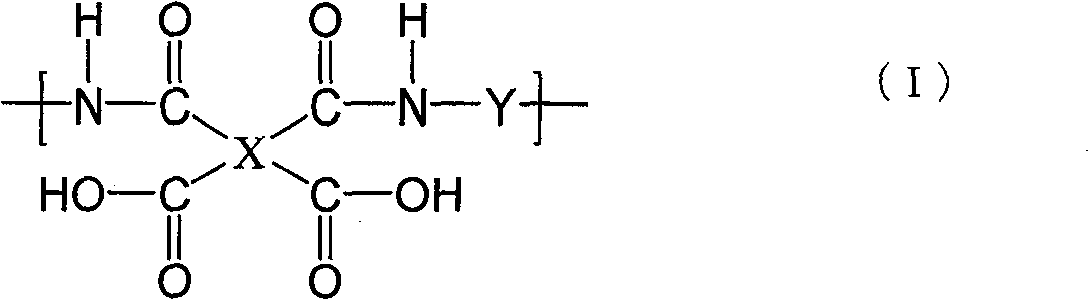

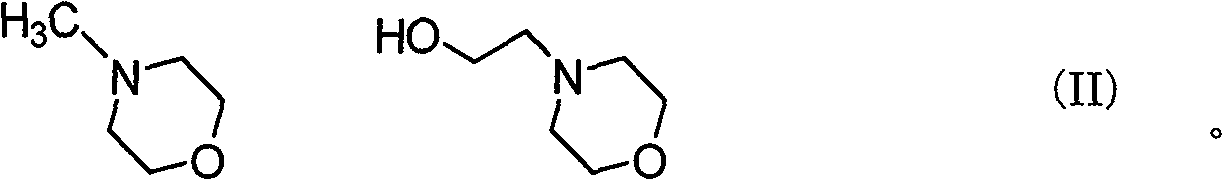

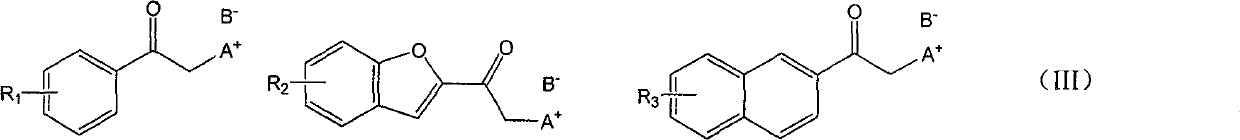

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] 5.88 g (0.0200 mol) of BPDA as an acid dianhydride, 3.43 g (0.0162 mol) of o-DDBP and 0.84 g (0.0029 mol) of APB as a diamine were dissolved in 53.29 g of DMAc. The molar ratio of acid dianhydride to diamine was 1.05. The polyamic acid solution of the polyimide precursor was obtained by stirring this solution for 12 hours. 10 wt% of photobase generator (C) was added with respect to the polyamic acid in the said polyamic-acid solution, and the negative photosensitive material solution was prepared.

[0154] Next, the above-mentioned solution was dropped onto a stainless steel foil having a thickness of 18 μm, a film was formed by spin coating, and pre-drying was performed at 80° C. for 5 minutes under a nitrogen atmosphere. The film thickness of the negative photosensitive material after pre-drying was 17 μm. Afterwards, with an ultra-high pressure mercury lamp, the negative photosensitive material film after the above-mentioned pre-drying is irradiated with 2000mJ / cm ...

Embodiment 2

[0171] 5.88 g (0.0200 mol) of BPDA which is an acid dianhydride, and 3.87 g (0.0182 mol) of o-DDBP which are diamines were dissolved in 39.01 g of DMAc. The molar ratio of acid dianhydride to diamine was 1.096. By stirring this solution for 12 hours, a polyamic acid solution was obtained. The photobase generator (C) was added so that it might be 30 wt% with respect to the polyamic acid in the said polyamic-acid solution, and the negative photosensitive material solution was prepared.

[0172] Next, as in Example 1, the above solution was dropped onto a 20 μm thick stainless steel foil to form a film by spin coating, and pre-dried at 100° C. for 5 minutes in a nitrogen atmosphere. Afterwards, irradiate 1000mJ / cm2 to the above-mentioned negative photosensitive material film after pre-drying through a photomask with an ultra-high pressure mercury lamp. 2 of active light. Furthermore, after post-curing by heating at 170 degreeC for 7 minutes in nitrogen atmosphere, it developed...

Embodiment 3

[0175] 5.88 g (0.0200 mol) of BPDA and 2.14 g (0.0066 mol) of BTDA which are acid dianhydrides, and 4.58 g (0.0216 mol) and 0.7622 g (0.0038 mol) of o-DDBP which are diamines were dissolved in 53.48 g of DMAc. The molar ratio of acid dianhydride to diamine was 1.050. By stirring this solution for 12 hours, a polyamic acid solution as a polyimide precursor was obtained. The photobase generator (C) was added so that it might be 30 wt% with respect to the polyamic acid in the said polyamic-acid solution, and the negative photosensitive material solution was prepared.

[0176]Next, as in Example 2, the above solution was dropped onto a 20 μm thick stainless steel foil to form a film by spin coating, and pre-dried at 100° C. for 5 minutes in a nitrogen atmosphere. Afterwards, irradiate 2500mJ / cm2 to the negative-type photosensitive material film after the above-mentioned pre-drying with ultra-high pressure mercury lamp through photomask 2 of active light. Furthermore, after post...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com