Nano composite nickel substitute alloy and manufacturing process thereof

A nickel-substituting alloy and nano-composite technology, which is applied in the field of nano-composite nickel-substituting alloy and its preparation, can solve the problems of accelerating the consumption of nickel resources, increasing costs, and the high price of nickel metal, so as to save strategic resources, increase benefits, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

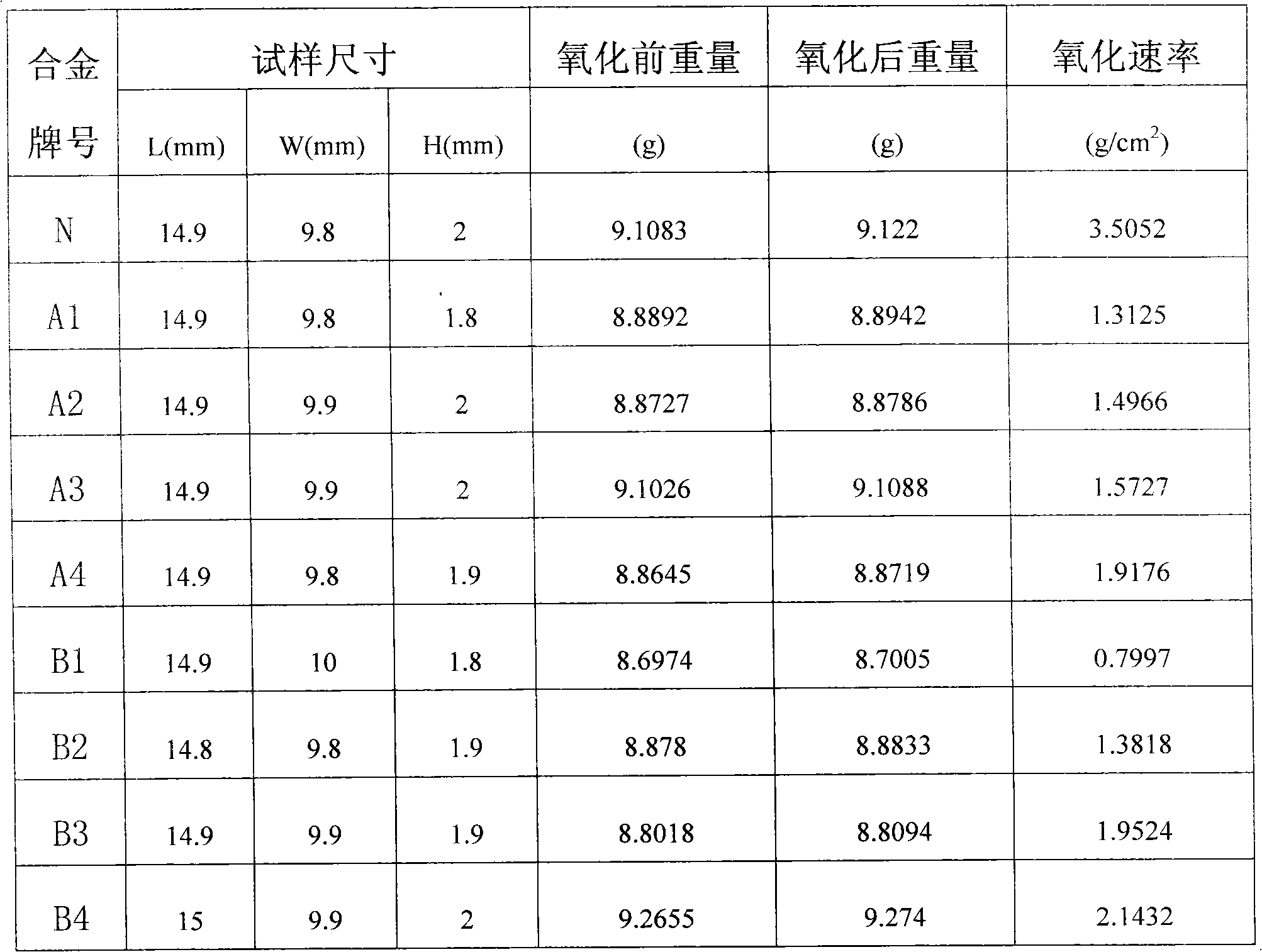

Image

Examples

preparation example Construction

[0022] The preparation process of the nano-composite nickel-substituting alloy for heat-resistant steel of the present invention, the preparation process is carried out according to the following steps: take each raw material according to the designed ratio, at first adopt polyvinyl butyral (code name is PVB)+dehydrated alcohol Add 20-45 grams of PVB to 1 liter of absolute ethanol to prepare a colloidal liquid with a certain viscosity; weigh nano-scale ceramic powder such as Al 2 o 3 , , MgO, CaO, (containing 5mol% of Y 2 o 3 ), etc., added to absolute ethanol to become a suspension state, and then dispersed into a single particle state by ultrasonic waves. If not, it is considered that the ultrasonic power cannot meet the test requirements, and the dispersed powder is unqualified. Then pour it into the agitator with "PVB+absolute ethanol glue" added in advance, and stir slowly at the beginning, that is, the rotation speed of the agitator is 80-120 rpm; then add other m...

Embodiment 1

[0025]The invention discloses a nano-composite nickel-substituting alloy for heat-resistant steel. The nickel-substituting alloy is prepared by compounding nano-ceramic powder, light metal with low melting point and high-density metal. The total weight of the prepared nickel substitute alloy is 5000g, and the ratio of various raw materials is: the total weight of nano-ceramic powder is 360g, of which TiO 2 The sum of the three weights of +MgO+CaO is 45g, that is, each component is 15g; ZrO 2 (containing 5mol% of Y 2 o 3 ) content is 50g; the rest is nano-Al 2 o 3 Powder. The sum of the weight of low-melting point metal aluminum and titanium is 400g, and 110g of aluminum powder is added thereto. The total weight of high-density metal iron, chromium, manganese and zinc is 4240g; 3000g of iron powder and 1140g of chromium powder are added; manganese and zinc each account for half of the remaining amount.

[0026] The above-mentioned preparation process is carried out accord...

Embodiment 2

[0028] The invention discloses a nano-composite nickel-substituting alloy for heat-resistant steel. The nickel-substituting alloy is prepared by compounding nano-ceramic powder, light metal with low melting point and high-density metal. The total weight of the prepared nickel substitute alloy is 5000g, and the ratio of various raw materials is: the total weight of nano-ceramic powder is 150g, of which TiO 2 The sum of the three weights of +MgO+CaO is 30g, that is, each component is 10g; the content of zirconia is 40g; the remaining 80g is nano-Al 2 o 3 Powder. The sum of the weight of low melting point metal aluminum and titanium is 250g, and 75g of aluminum powder is added thereto. The total weight of high-density metal iron, chromium, manganese and zinc is 4600g; 3360g of iron powder and 1140g of chromium powder are added; manganese and zinc each account for half of the remaining amount.

[0029] The above-mentioned preparation process is carried out according to the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com