Insulated wire, coil using the same, and motor

A technology of insulated wires and insulating layers, applied in the direction of insulated cables, insulated conductors, organic insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

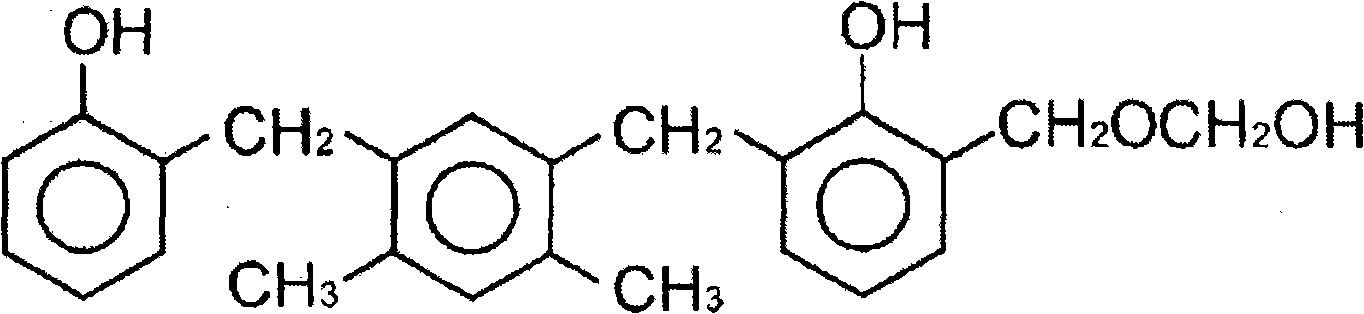

Method used

Image

Examples

Embodiment

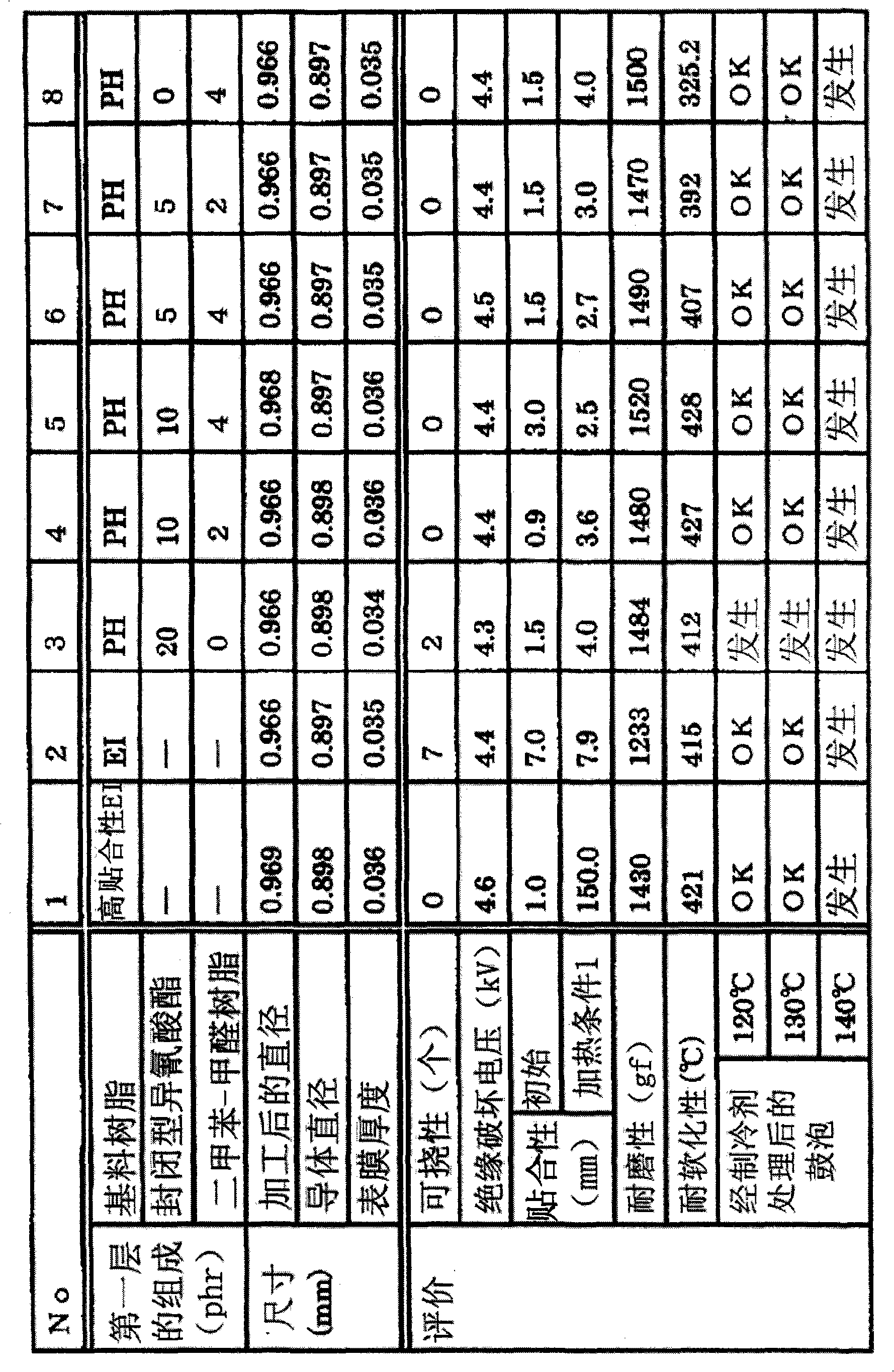

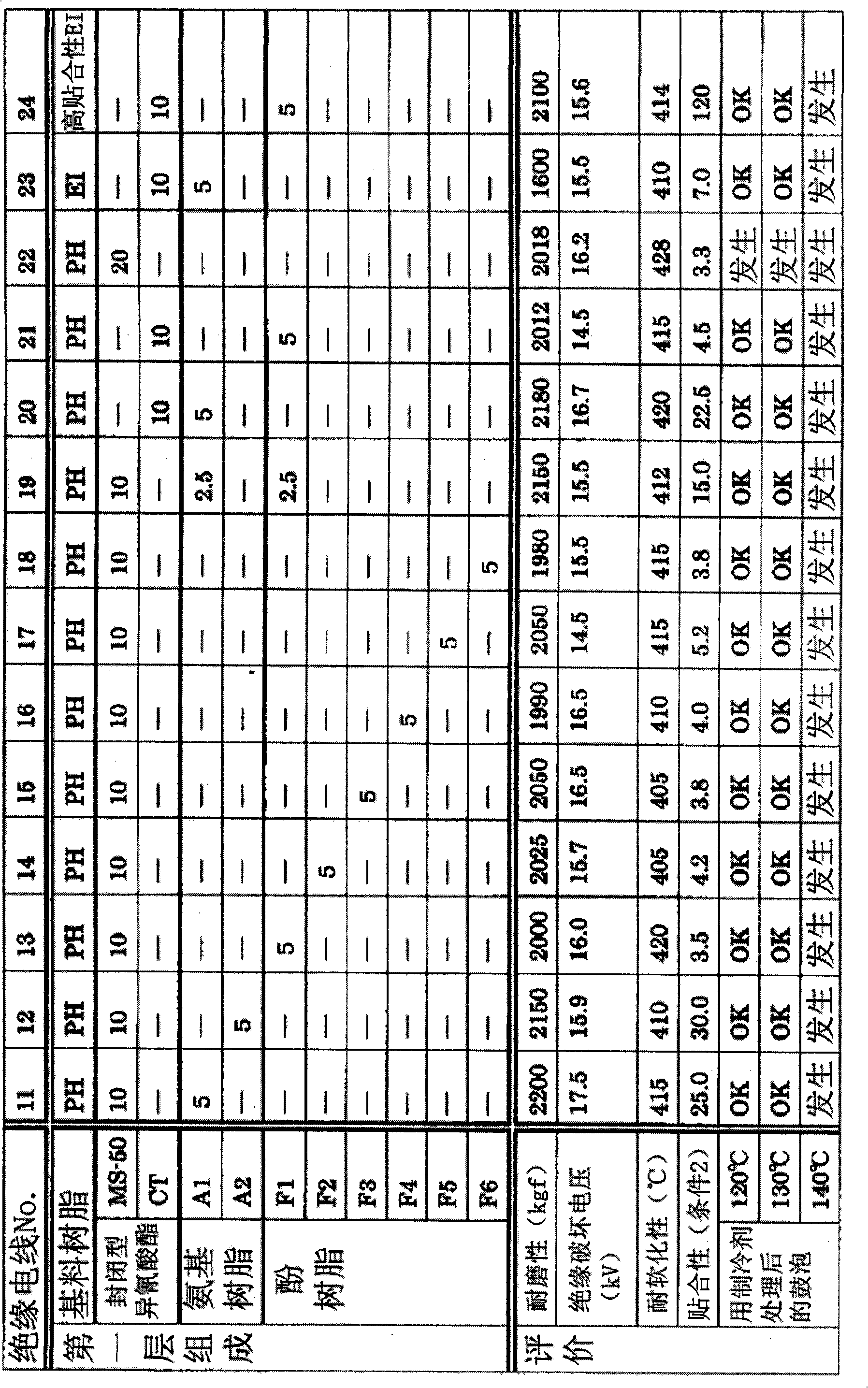

[0067] The preferred embodiment of the invention is illustrated by way of example. The examples do not limit the scope of the present invention.

[0068] [measurement evaluation method]

[0069] First, the evaluation method employed in this example will be described.

[0070] (1) Flexibility

[0071] The insulated wire was stretched by 30% relative to the initial length, and after stretching, it was tested according to JIS C30037.1.1 flexibility test standard. Specifically, the wire was wound 10 times around a round bar having the diameter of the insulated wire itself so that the wires were in contact with each other, and the presence or absence of cracks was observed and the number of cracks was counted.

[0072] (2) Dielectric breakdown voltage (kV)

[0073] Measurement was performed in accordance with JIS C3003 10.2.2. Specifically, a 25 cm electric wire was dipped in a solution of glycerin / saturated NaCl water=85 / 15. The impregnated copper plate is used as the counter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com