Method for hydrolyzing lactoalbumin by enzyme method and hydrolysate thereof

A hydrolyzed whey protein and whey protein hydrolysis technology, applied in protein food processing, animal protein processing, protein food ingredients and other directions, can solve problems such as affecting the taste and flavor of products, and achieve low bitterness, improved taste, and easy digestion and absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

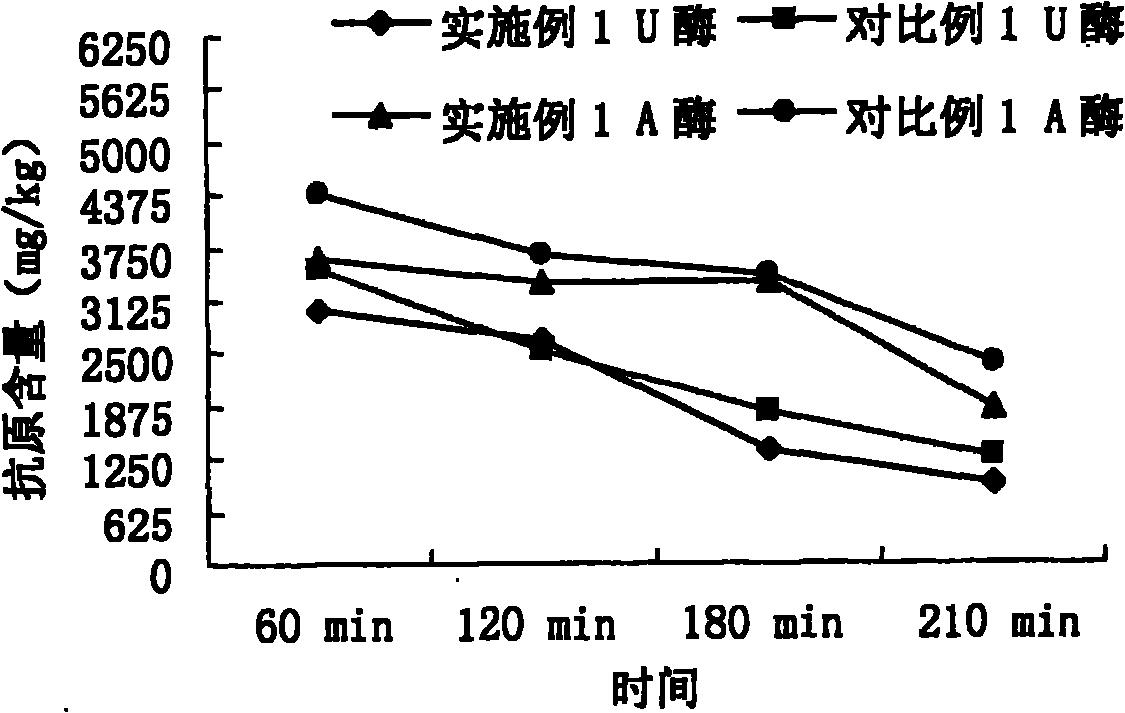

[0039] Prepare 2 parts of 8% WPC80 aqueous solution, adjust the solution to the optimum pH value of 7.0 with 1N sodium hydroxide, then heat-treat in a water bath at 80°C for 10 minutes, cool down to 55°C, add protease U to 1 part, and protease A to 1 part, The amount of enzyme used was 20000U / 100mL whey protein aqueous solution, hydrolyzed at 55°C for 210min respectively; observe the change of pH value during the hydrolysis process, take samples at different times during the hydrolysis process, heat inactivate the protease in the sampled samples immediately after sampling, and inactivate The activation temperature is 95° C., and the time is 10 minutes. After inactivation, it is rapidly cooled to room temperature, and the pH value, bitter taste and allergen index (antigen content) of the hydrolyzate are measured. During the hydrolysis process, the pH value gradually decreased, and the pH value decreased to 6.35-6.4 after 210 minutes of hydrolysis. Please refer to Table 1 for the...

Embodiment 1 and comparative example 1

[0043] Example 1 and Comparative Example 1 Please refer to the following table 1 for the comparison of the bitterness change of the hydrolyzate in the process of hydrolyzing whey protein with protease U and protease A:

[0044] Table 1

[0045]

[0046] Note: "-" means no bitterness, "+" means weaker bitterness, with the increase of "+", the bitterness also increases.

[0047] As can be seen from Table 1: in the process of enzymatically hydrolyzing whey protein, as the hydrolysis time prolongs, the bitterness of the hydrolyzate gradually increases; The bitterness of the product will be significantly reduced.

Embodiment 2

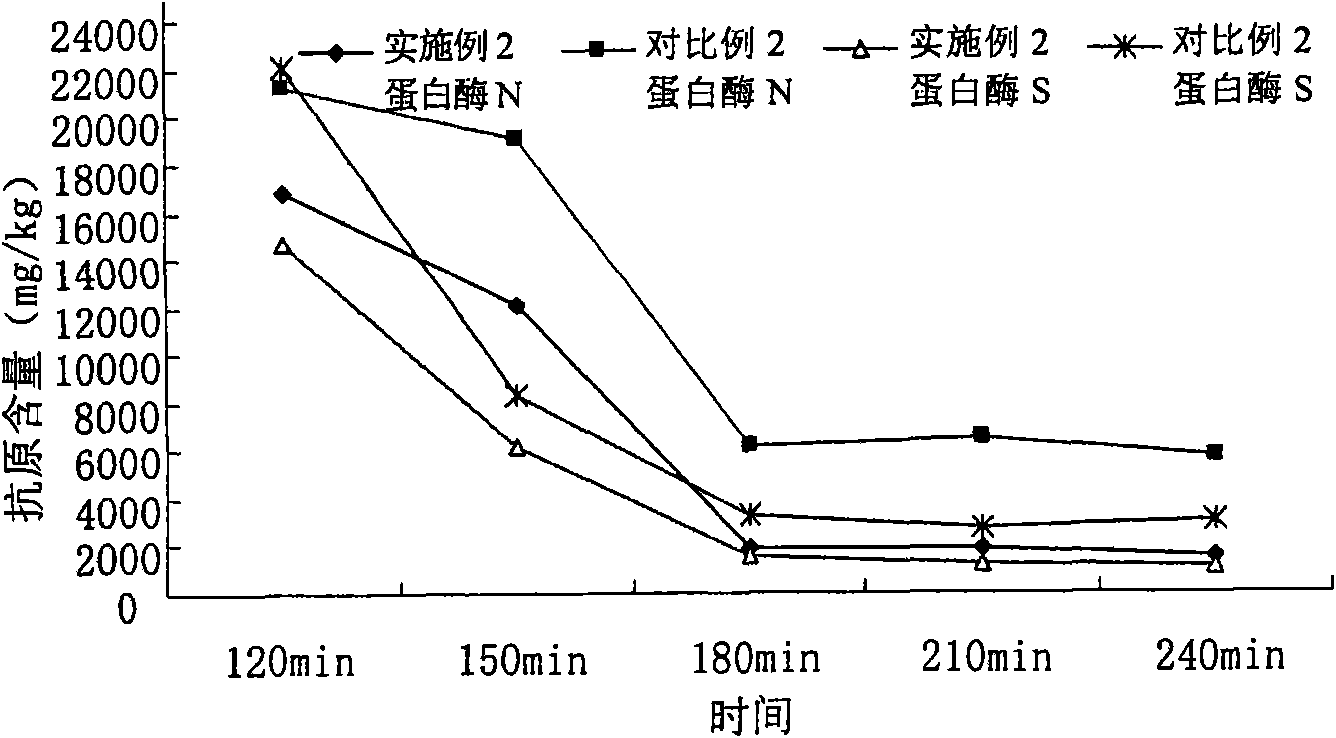

[0049] Prepare 2 parts of 10% WPC80 aqueous solution, adjust the solution to pH 7.0 suitable for enzymatic hydrolysis with 1N sodium hydroxide, then heat-treat in a water bath at 85°C for 10 minutes, cool down to 60°C, keep warm, add protease N to 1 part, and protease S to 1 part , the amount of enzyme used is 21000U / 100mL whey protein aqueous solution, hydrolyzed at 60°C for 240min respectively; observe the pH value change during the hydrolysis process, take samples at different times during the hydrolysis process, and inactivate the protease in the sampled samples in a boiling water bath for 10 minutes after sampling After inactivation, it is rapidly cooled to room temperature, and the pH value, bitter taste and allergen index (antigen content) of the hydrolyzate are determined. During the hydrolysis process, the pH value gradually decreased, and the pH value decreased to 6.35-6.4 after 240 minutes of hydrolysis. Please refer to Table 2 for the test results of bitter taste e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com