Ophthalmic implanted material with shape memory function and preparation method thereof

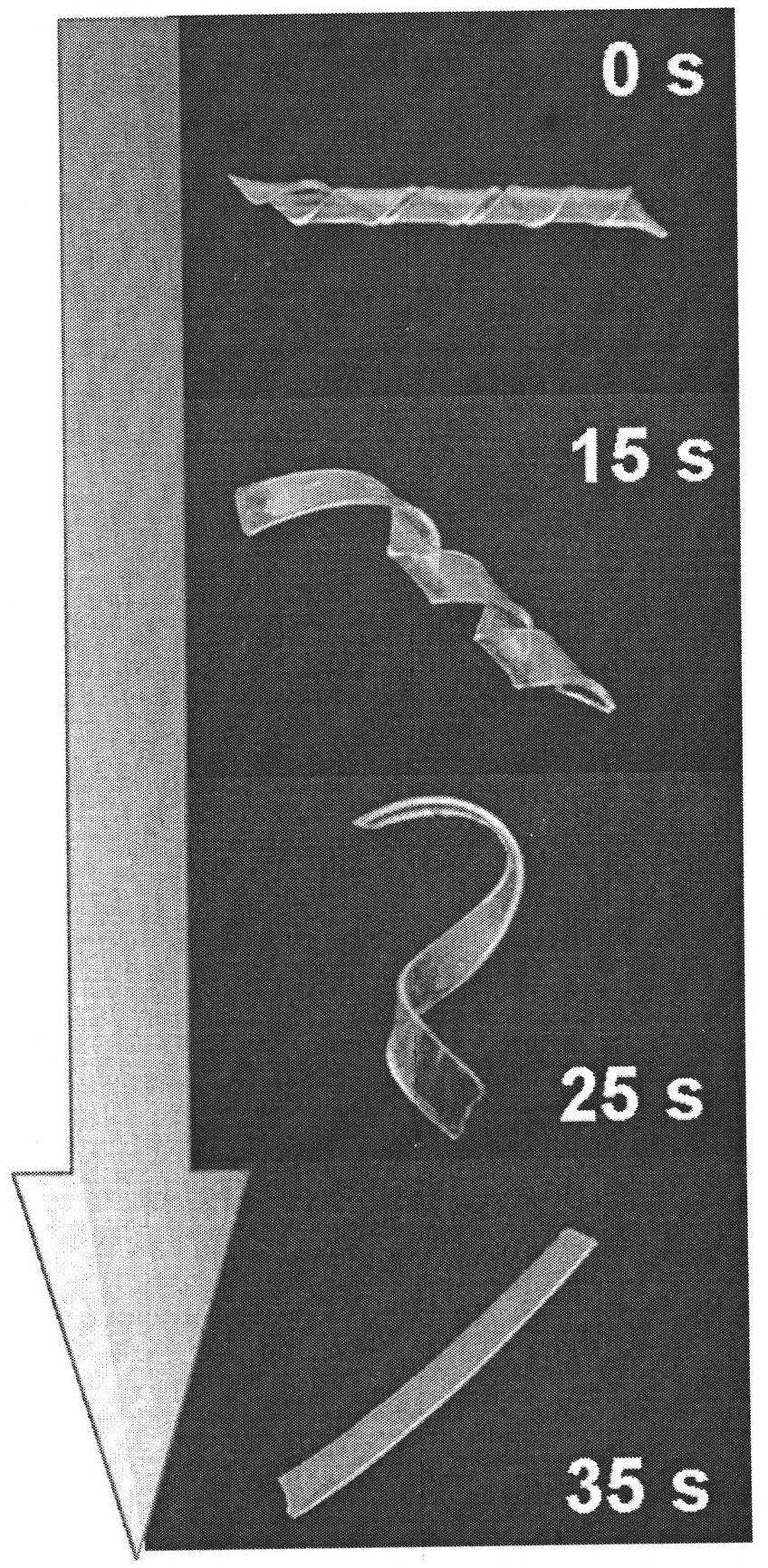

An implant material and memory technology, applied in medical science, prosthesis, etc., can solve the problems of many postoperative complications, large implant incision, material can not be filled, etc., and achieve the effect of large material deformation and high light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

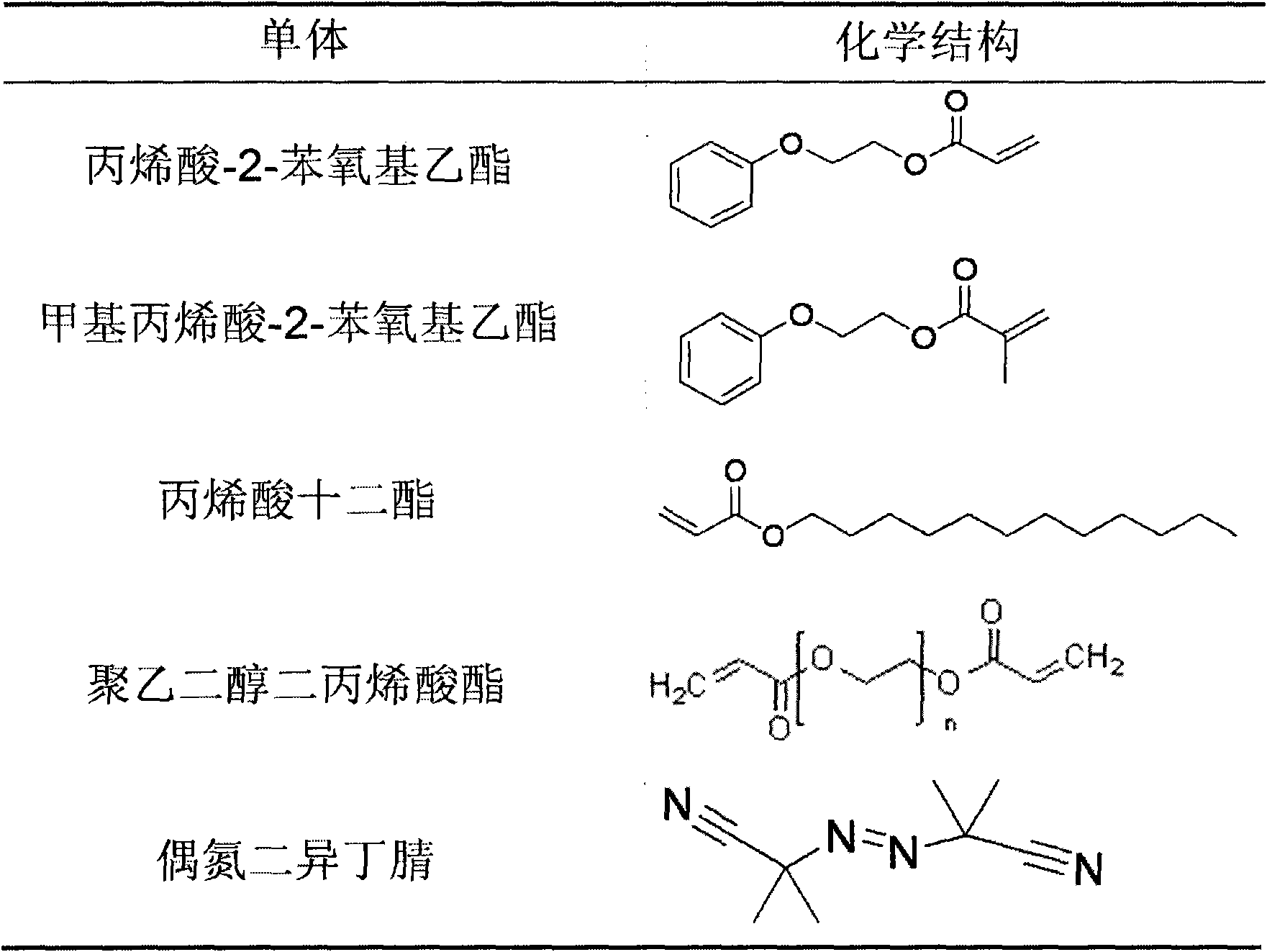

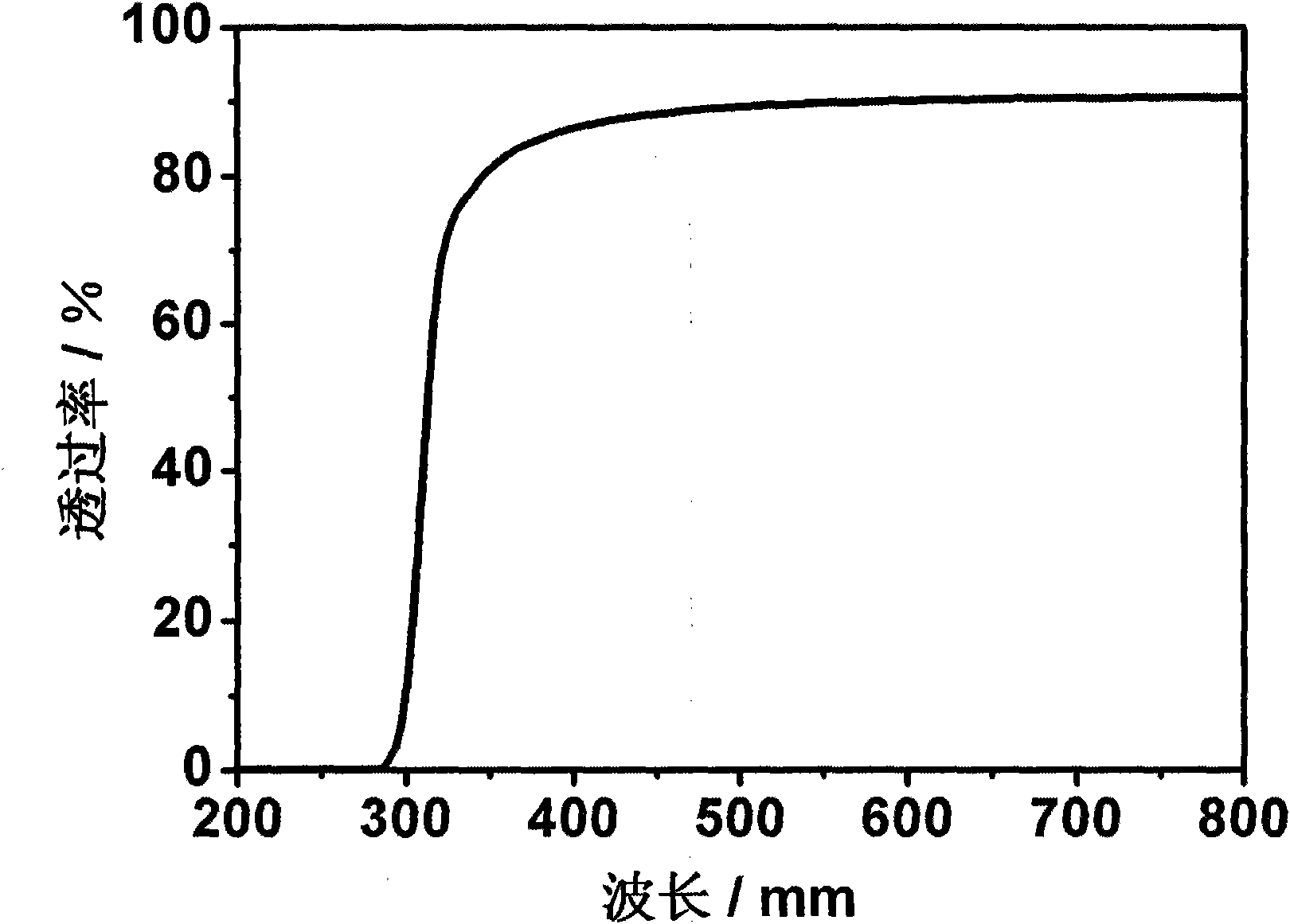

[0028] The selected monomers are (a): 2-phenoxyethyl acrylate (Sigma-Aldrich Company), (b): 2-phenoxyethyl methacrylate (Sigma-Aldrich Company). The molar ratio of the selected monomers is a / b=4 / 1, and the molar content of the two is 90.0%. The crosslinking agent is polyethylene glycol diacrylate 400 (Sigma-Aldrich company), and the molar content is 10.0%. %, the content of the added thermal initiator (azobisisobutyronitrile, Shanghai Fourth Chemical Reagent Company) is 0.5% of the total mass. Mix the monomer, cross-linking agent and initiator uniformly under the protection of nitrogen, then pour into the mold, heat and polymerize in an oven at 80°C for 24 hours, perform Soxhlet extraction to remove unreacted monomers and oligomers, and make shape-memory acrylate Material. The refractive index of the material is 1.51, and the transmittance in the visible light region is as follows: figure 2 As shown, the glass transition temperature is 29.5°C, the elastic modulus is 4.07MPa...

example 2

[0030] The selected monomers are (a): 2-phenoxyethyl acrylate (Sigma-Aldrich Company), (b): 2-phenoxyethyl methacrylate (Sigma-Aldrich Company). The selected monomer molar ratio is a / b=4 / 1, and the molar content of the two is 95.0%, and the crosslinking agent is polyethylene glycol diacrylate 1000 (Sigma-Aldrich company), and the molar content is 5.0 %, the content of the added thermal initiator (azobisisobutyronitrile, Shanghai Fourth Chemical Reagent Company) is 0.5% of the total mass. Mix the monomer, cross-linking agent and initiator uniformly under the protection of nitrogen, then pour into the mold, heat and polymerize in an oven at 75°C for 36 hours, perform Soxhlet extraction to remove unreacted monomers and oligomers, and make shape-memory acrylate Material. The refractive index of the material is 1.52, and the transmittance in the visible light region is as follows: Figure 4 As shown, the glass transition temperature is 19.4°C, the elastic modulus is 1.37MPa, the ...

example 3

[0032] The selected monomers are (a): 2-phenoxyethyl acrylate (Sigma-Aldrich Company), (b): lauryl acrylate (Tianjin Tianjiao Chemical Co., Ltd.). The selected monomer molar ratio is a / b=5 / 1, and the molar content of the two is 90.0%, and the crosslinking agent is polyethylene glycol dimethacrylate 600 (Sigma-Aldrich company), and the molar content The content of the thermal initiator (azobisisobutyronitrile, Shanghai Fourth Chemical Reagent Company) added was 0.5% of the total mass of the monomers. Mix the monomer, cross-linking agent and initiator uniformly under the protection of nitrogen, then pour into the mold, heat and polymerize in an oven at 75°C for 24 hours, perform Soxhlet extraction to remove unreacted monomers and oligomers, and make shape-memory acrylate Material. The refractive index of the material is 1.51, and the transmittance in the visible light region is as follows: Figure 5 As shown, the glass transition temperature is 21.2°C, the elastic modulus at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com