Magnetic field induced patterned assembly and erasable magnetically controlled phase-change material and preparation method thereof

A phase-change material and pattern-induced technology, which is applied in the direction of diamagnetic/paramagnetic materials, magnetic materials, magnetic objects, etc., can solve the problems of stable pattern shape, pattern can not be erased, etc., to achieve simple method and low material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

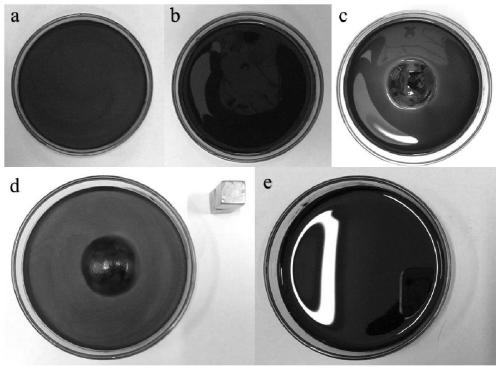

[0041] Preparation of Surface Nonpolar Modified Superparamagnetic Nanomaterials / Low Temperature Phase Change Nonpolar Polymer Composite

[0042] (1) Weigh 0.5g nanometer Fe 3 o 4 Add to 80mL of anhydrous N,N-dimethylformamide (DMF), ultrasonic for half an hour to ensure stable dispersion, dropwise add 1mL of ethanol containing 20% γ-glycidyl etheroxypropyltrimethoxysilane surfactant solution, the solution was added into a three-necked flask, mechanically stirred and reacted at 70°C for 2 hours, washed with ethanol and dried after the reaction;

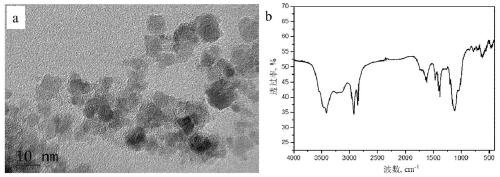

[0043] (2) Add the dried product to 100mL DMF, add 0.8g octadecylamine, react at 80°C for 5 hours, magnetically separate after the end, wash with DMF hot solution, remove residual octadecylamine, and use tetrachloride Dissolve superparamagnetic nanomaterials with carbonized carbon, remove insoluble matter by suction filtration, and evaporate the solution to obtain modified superparamagnetic nanomaterials. Its TEM and infrared spect...

Embodiment 2

[0053] Preparation of Surface Polarity Modified Superparamagnetic Nanomaterials / Low Temperature Phase Change Polar Polymer Composite

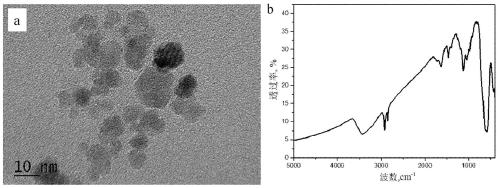

[0054] (1) Weigh 0.5g nanometer Fe 3 o 4 Add to 10mL water, add 3mL dimethyloctadecyl[3-trimethoxysilylpropyl]ammonium chloride methanol solution (mass fraction is 40%), add dropwise ammonia solution with pH=12, adjust pH to 10 , stirred and aged at room temperature for 24 hours, washed with water and methanol for several times, magnetically separated, dissolved in tetrahydrofuran, removed by suction filtration, and evaporated to dry the solution to obtain a superparamagnetic nanomaterial with a quaternary ammonium salt function on the surface;

[0055] (2) Take 10 g of polyethylene glycol monomethyl ether with a molecular weight of 2000, add 0.5 g of sulfamic acid and 0.08 g of urea, heat to 120 ° C for 5 hours, dissolve with 100 mL of ethanol after the reaction is completed, filter, evaporate to dryness, A polymer salt having a sulfonate en...

Embodiment 3

[0060] With reference to Example 1, the superparamagnetic nanomaterial / low temperature phase change nonpolar polymer composite material of surface nonpolar modification is prepared, the difference is that in step (2), the nanomagnetic material with epoxy group and alkane The reaction temperature of the amine was 65° C., and the reaction time was 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com