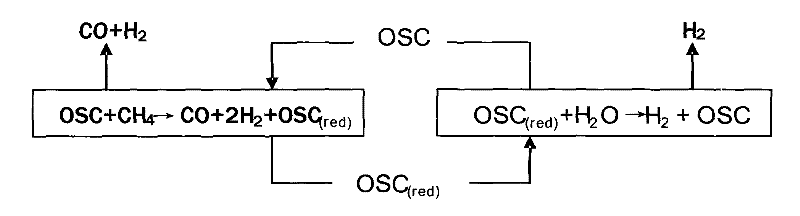

Oxygen carrier for preparing hydrogen and synthesizing gas by reforming steam through two-step method

A technology of steam reforming and oxygen carrier, applied in the field of energy chemistry, can solve the problems of general performance of oxygen carrier, and achieve the effect of reasonable cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Implementation conditions

[0027] Preparation of LaFeAl by co-precipitation method 11 O 19 The precursor is dried at 120°C for 12 hours, pre-baked at 300°C for 2 hours, and baked at 1200°C for 4 hours to obtain LaFeAl 11 O 19 , LaFeAl 11 O 19 LaFeAl is prepared by dipping method 11 O 19 / Ce-ZrO 2 , The chemical formula is (LaFeAl 11 O 19 ) 0.3 (Ce 0.6 Zr 0.4 O 2 ) 0.7 Oxygen carrier.

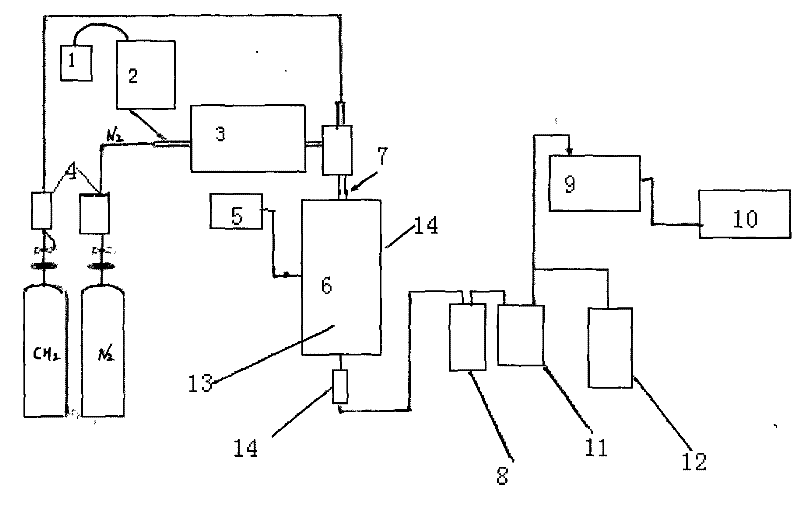

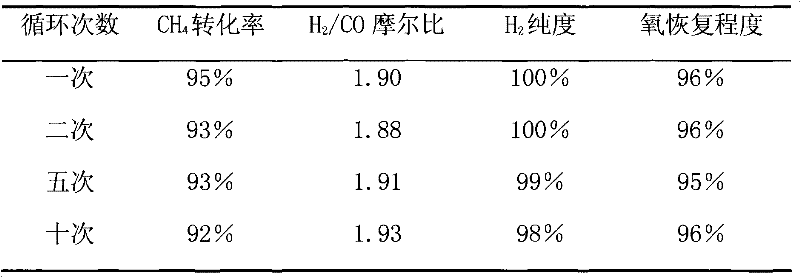

[0028] As shown in the figure, put 5.4g of oxygen carrier in the quartz reactor to check the air tightness of the device; blow nitrogen to exhaust other gases in the system, and then heat the reactor at a rate of 10°C / min to 850°C; 10Ncm 3 Pass methane for 10 minutes, collect the tail gas, and sample for chromatographic analysis. In the second step, stop the methane supply, keep the reactor temperature unchanged, and then pass the nitrogen gas for 10 minutes and then add 400℃ steam to regenerate the oxygen carrier. At the same time, hydrogen is produced, the water vapor flow is 1.8g / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com