Novel oversize burning-free mullite bedding brick

A super-sized, mullite technology, applied in the field of new super-sized unburned mullite paving bricks, can solve the problems of reduced density and strength, high porosity, etc. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] 1) Determine the optimal ratio of aggregate

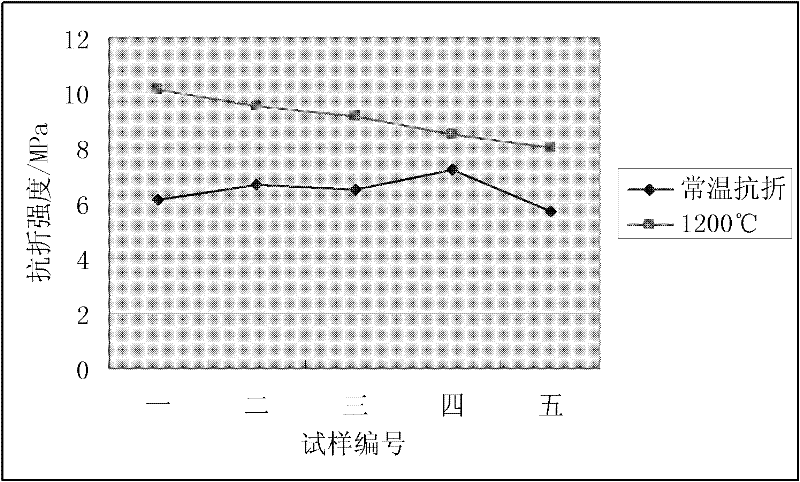

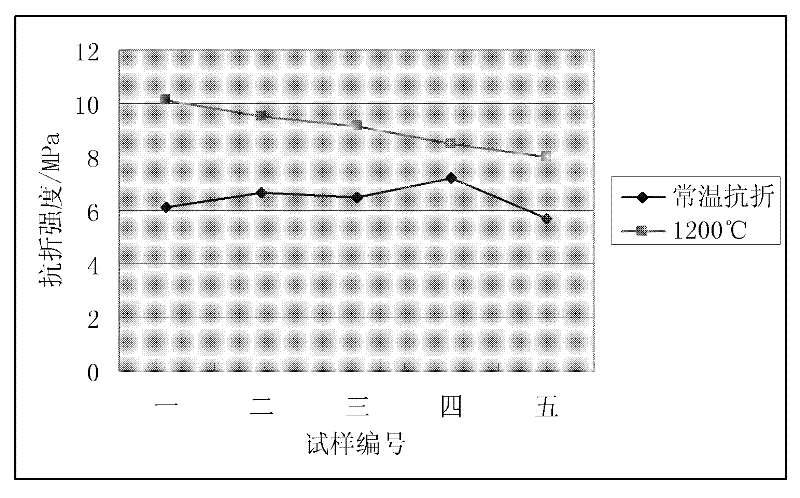

[0033] In this experiment, a group of formulations were designed to determine the optimal ratio of aggregates. The experimental formulations are shown in Table 1. For the flexural strength, see figure 1 .

[0034] Table 1 Different aggregate ratios

[0035]

[0036] According to the flexural strength test, the composite index of room temperature flexural strength and 1200°C flexural strength of formula A2 is better than other formulas. This formula has certain room temperature strength and high flexural strength at 1200°C. So we decided to choose the aggregate formulation of the second group of samples as the aggregate ratio in the future.

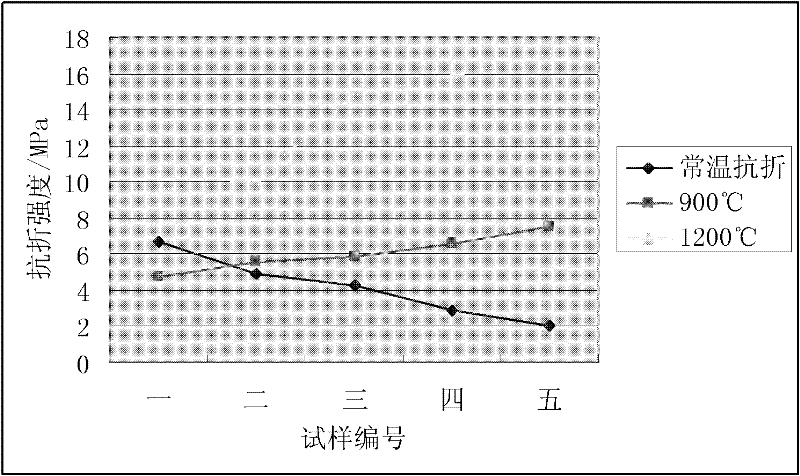

[0037] 2) Determination of the amount of cement and silica fume

[0038] Since the high cement consumption will cause the performance of the product to decline at medium and high temperatures, it is necessary to reduce the cement consumption as low as possible. The solution to this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com