Soluble and high-temperature resistant aromatic polyimide and preparation method thereof

A polyimide, high temperature resistant technology, applied in the field of soluble high temperature resistant aromatic polyimide and its preparation, can solve the problem of restricting the use of printed circuit boards, reducing the heat resistance of the adhesive system, and the oxidation reaction of copper foil and other problems, to achieve the effect of excellent thermal stability

Inactive Publication Date: 2010-07-28

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF5 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this method is that due to the use of a large amount of aliphatic diamines, the heat resistance of the adhesive system is greatly reduced, and its glass transition temperature is 150-200 ° C, which limits the use of printed circuit boards in high-temperature environments. use in

Its main disadvantage is that it needs long-term high-temperature curing at a high temperature of 350°C

This not only consumes energy, puts forward higher technical requirements for equipment, but also easily oxidizes copper foil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

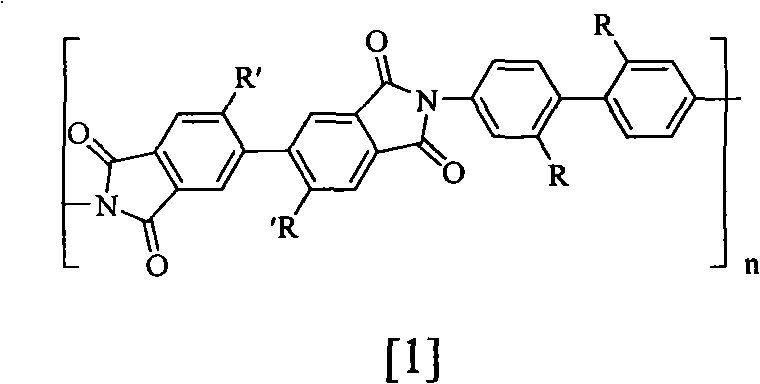

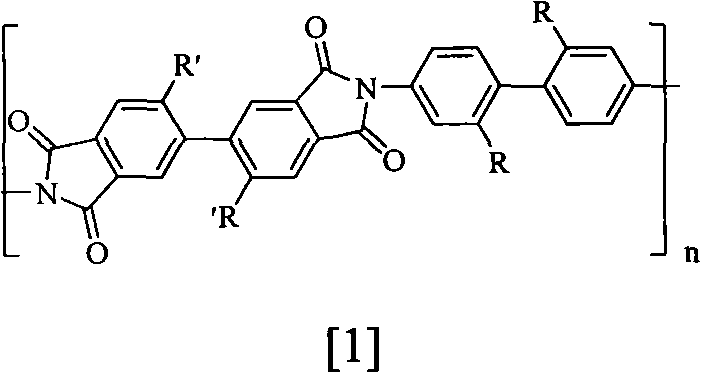

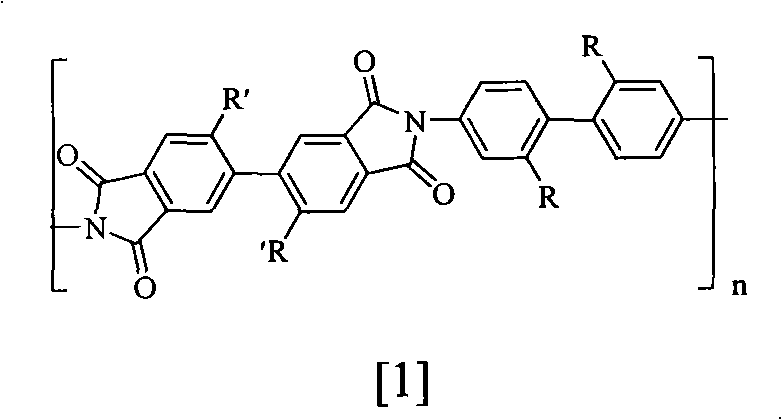

The invention discloses soluble and high-temperature resistant aromatic polyimide and a preparation method thereof. The preparation method comprises the following steps: stirring a 2,2'-R,R-4,4'-diaminodiphenyl compound and a 2,2'-R,R-4,4',5,5'-diphenyltetracarboxylic dianhydride compound in molar ratio of 1 to 1 in a strongly polar non-proton organic solvent at the room temperature to obtain homogeneous-phase, transparent and viscous polyimide solution; and dehydrating the polyimide solution to obtain the soluble and high-temperature resistant aromatic polyimide. The soluble and high-temperature resistant aromatic polyimide has the polyimide of the repetitive unit of a general formula [1] that number average molecular weight Mn is equal to 8,000 to 20,000; molecular weight distribution Mw / Mn is equal to 1.2 to 1.7; and R is a group in the 2,2'-R,R-4,4'-diaminodiphenyl compound, and R' is a group in the 2,2'-R,R-4,4',5,5'-diphenyltetracarboxylic dianhydride compound. The aromatic polyimide is soluble in the high-temperature or chemical dehydration full ring closure of weakly polar solvents.

Description

technical field The invention belongs to the synthesis technology of aromatic polyimide, in particular to a soluble high-temperature-resistant aromatic polyimide and a preparation method thereof. Background technique Polyimide is a kind of polymer with excellent comprehensive performance, which has excellent heat resistance, low temperature resistance, self-lubrication, radiation resistance and flame retardancy, as well as excellent mechanical properties and dielectric properties . Therefore, it is widely used in high-temperature radiation-resistant materials such as spacecraft, satellites, and space vehicles; advanced structural composite materials, electrical insulation materials, high-temperature-resistant adhesives, and high-temperature-resistant sealing materials in aerospace, automobiles, electromechanical, etc. In the field of microelectronics, it can be used as the base material of FPC or PCB, the interlayer insulation material of IC, the passivation coating of very...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G73/10

Inventor 沈应中李月琴

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com