Air conditioner fan material and production method thereof

A fan and air-conditioning technology, applied in the direction of non-volume pumps, mechanical equipment, pumps, etc., can solve the problems of low comprehensive performance indicators such as strength, poor antibacterial performance, troublesome process, etc., and achieve short antibacterial validity period and high heat resistance temperature , the effect of low application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

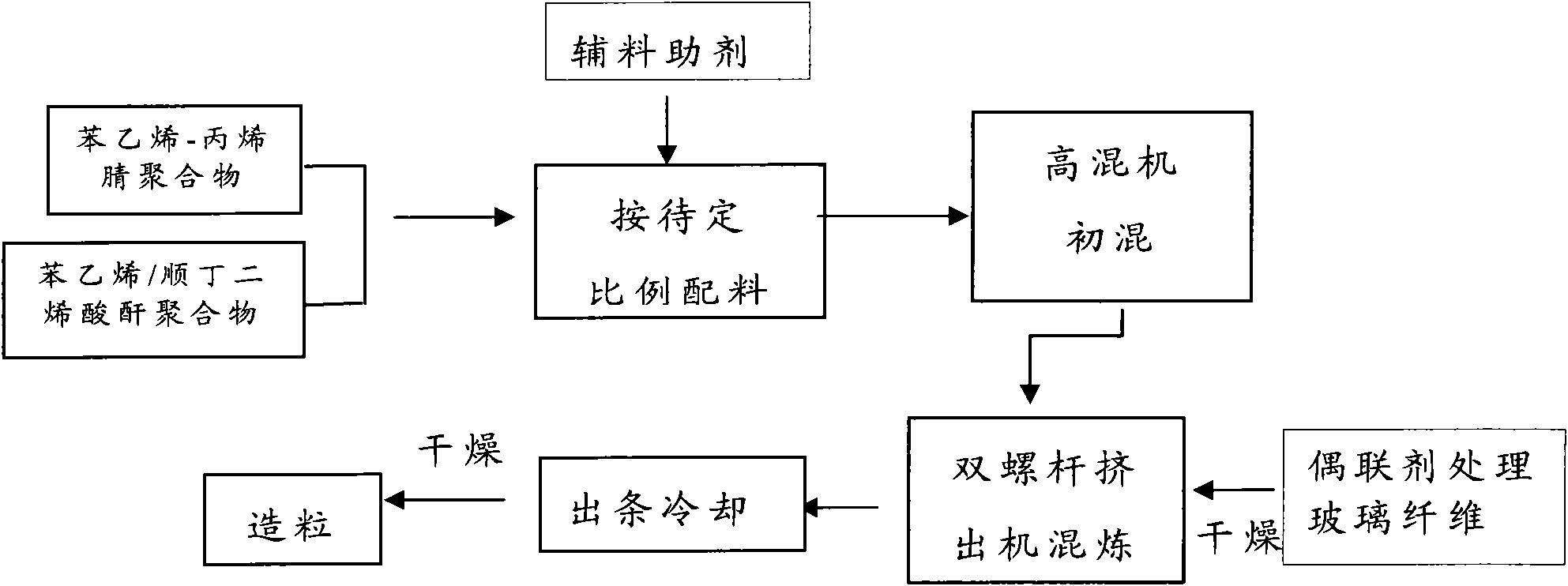

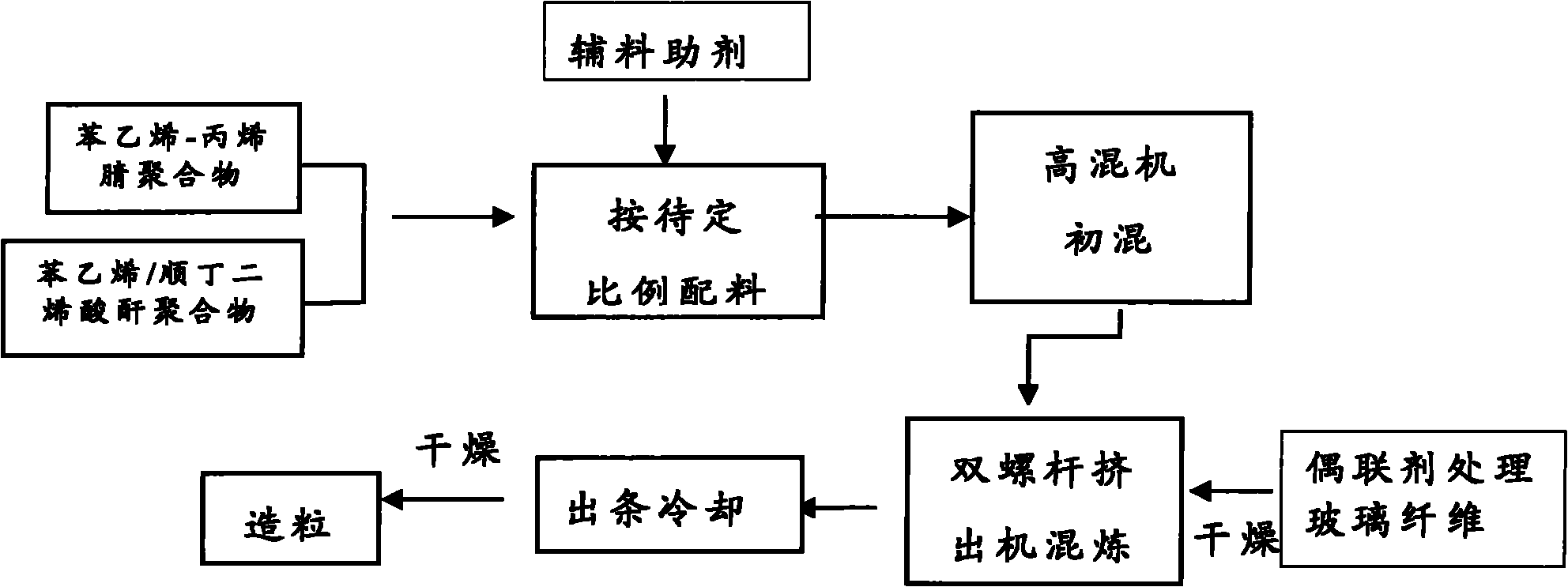

Method used

Image

Examples

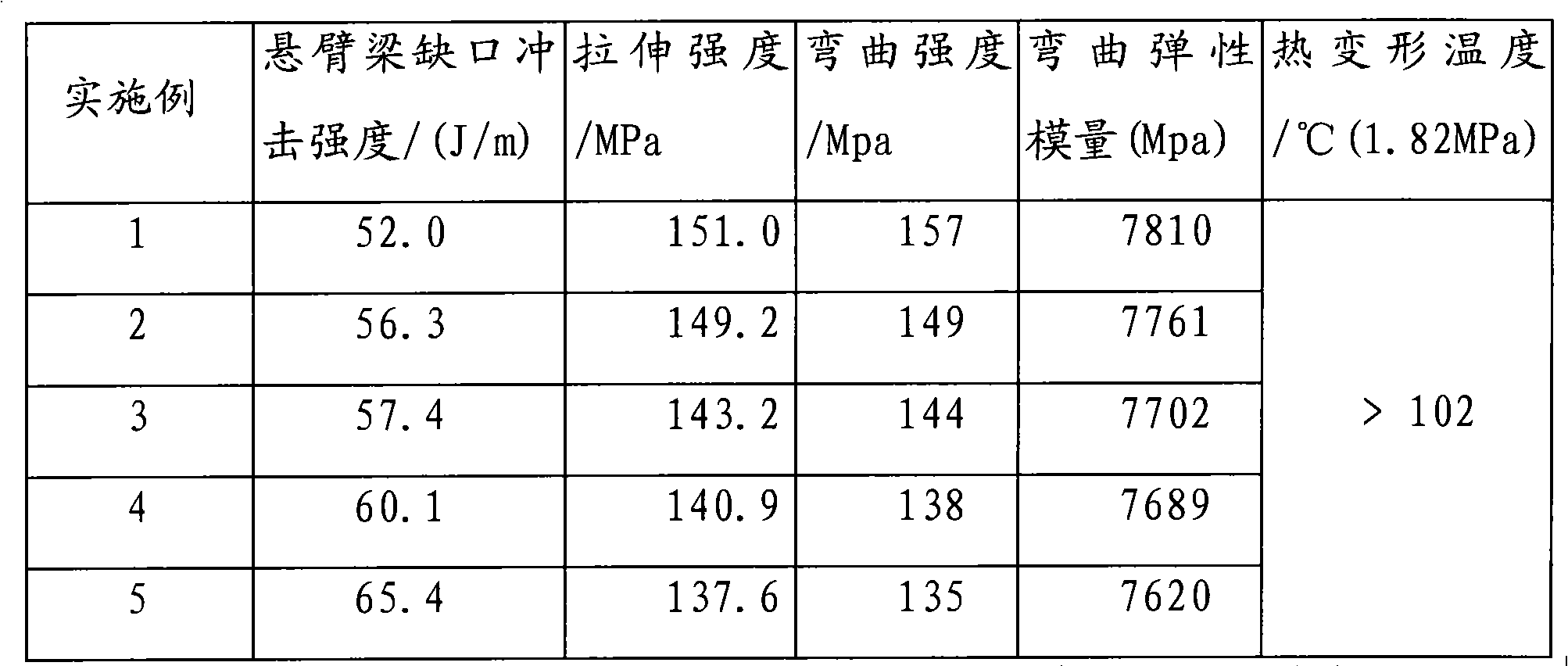

Embodiment 1

[0026] Implementation 1, unit: kg.

[0027] 65 parts of styrene-acrylonitrile polymer, 5 parts of styrene-maleic anhydride polymer, 30 parts of pretreated alkali-free short glass fiber, 0.4 part of antioxidant 1010, 1 part of zeolite-loaded silver antibacterial agent, nano Zinc oxide 1.5 parts, lubricant EBS 1.0 parts.

Embodiment 2

[0028] Implementation 2, unit: kg.

[0029] 72 parts of styrene-acrylonitrile polymer, 3 parts of styrene-maleic anhydride polymer, 25 parts of pretreated alkali-free short glass fiber, 0.4 part of antioxidant 1076, 1.0 part of zeolite-loaded silver antibacterial agent, nano Zinc oxide 1.5 parts, lubricant EBS 1.0 parts.

Embodiment 3

[0030] Implementation 3, unit: kg.

[0031] 70 parts of styrene-acrylonitrile polymer, 5 parts of styrene / maleic anhydride polymer, 25 parts of pretreated alkali-free short glass fiber, 0.48 parts of antioxidant 1010, 2.0 parts of zeolite-loaded silver antibacterial agent, nano Zinc oxide 1.5 parts, lubricant EVA 1.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com