Cotton-flax stalk charcoal-making combustion furnace and streamline formed by same

A combustion furnace and assembly line technology, used in coke ovens, biofuels, special forms of dry distillation, etc., can solve problems such as the high value of heat for domestic use, and achieve the effects of improving equipment utilization, controlling air pollution, and widening raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

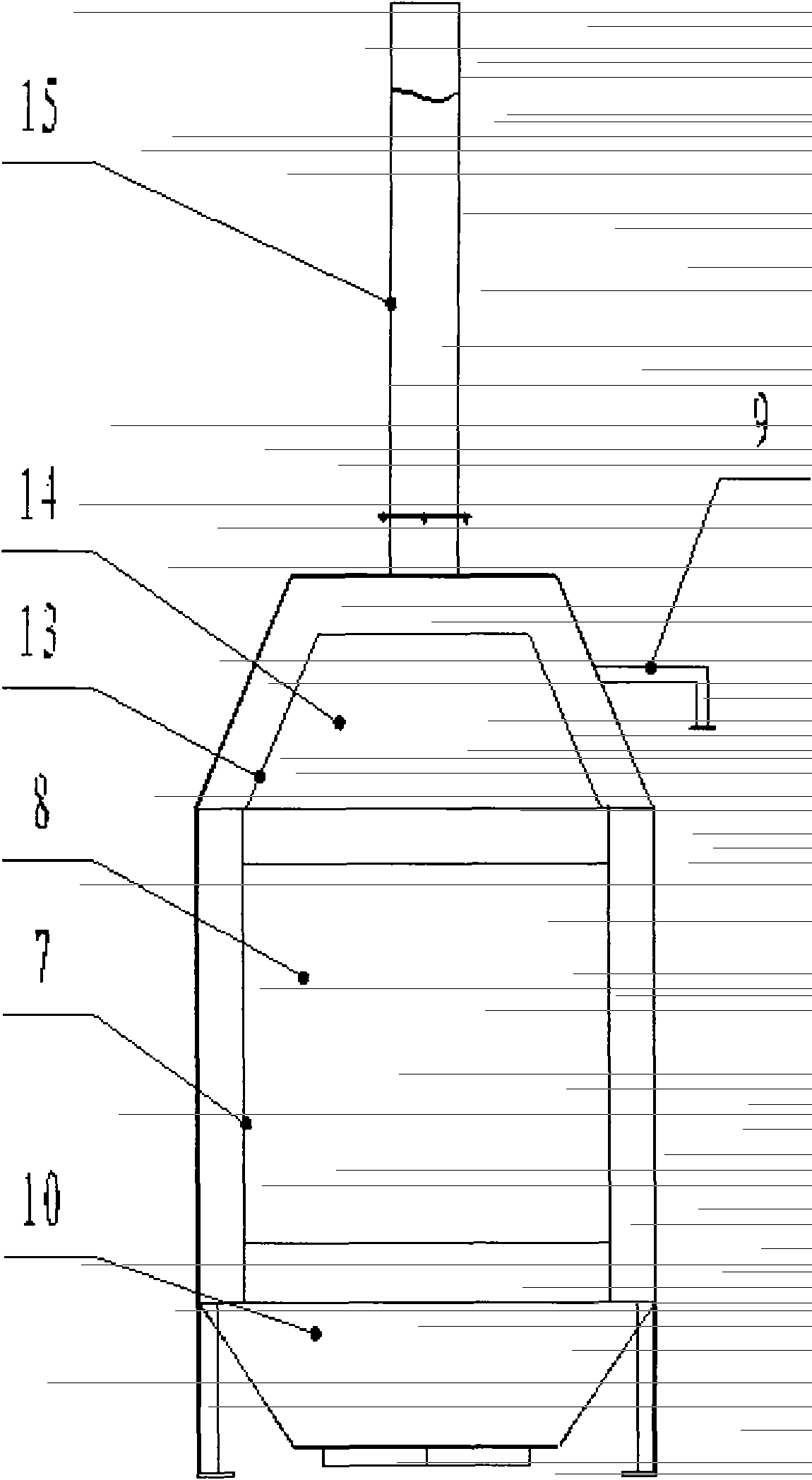

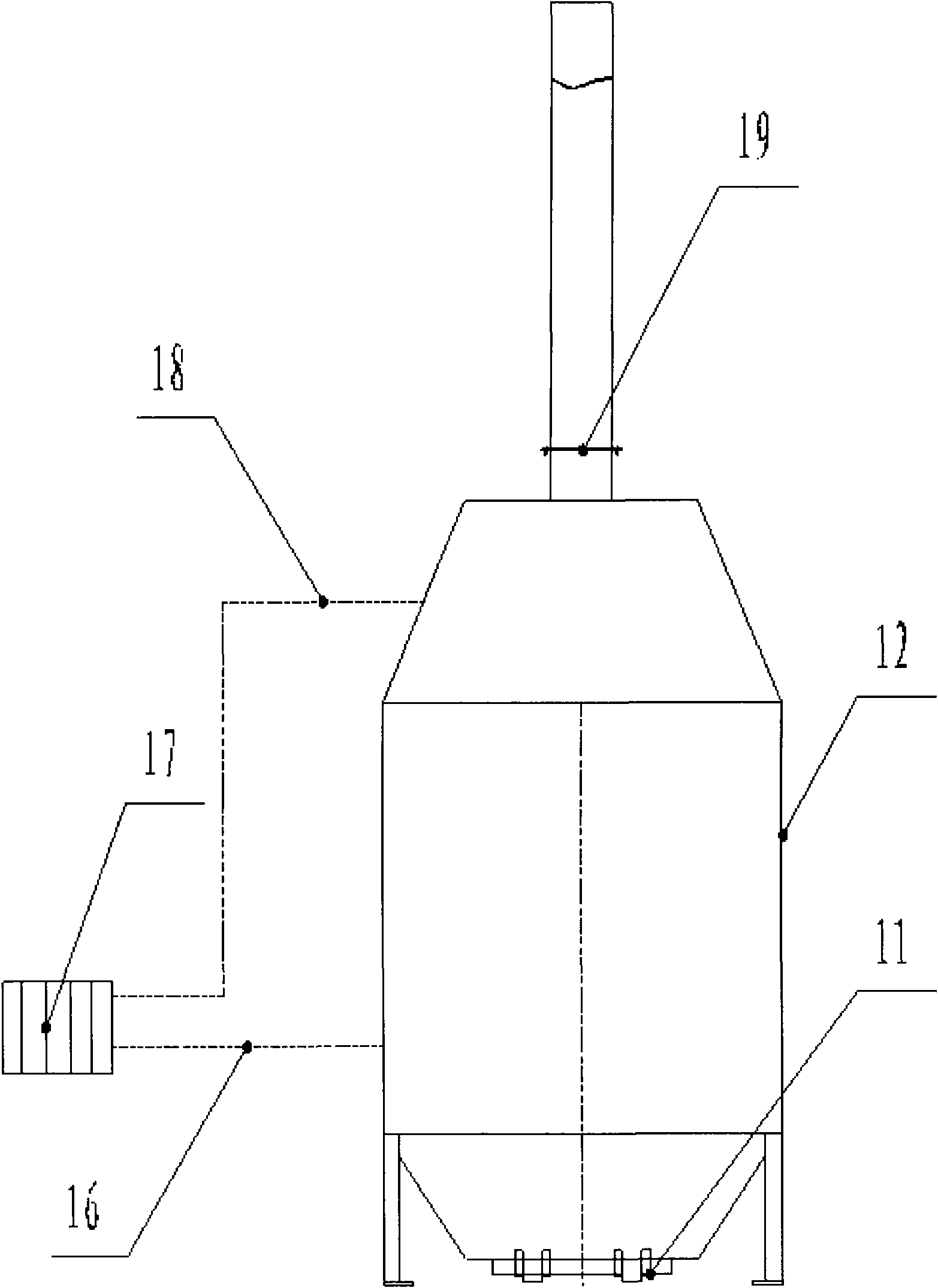

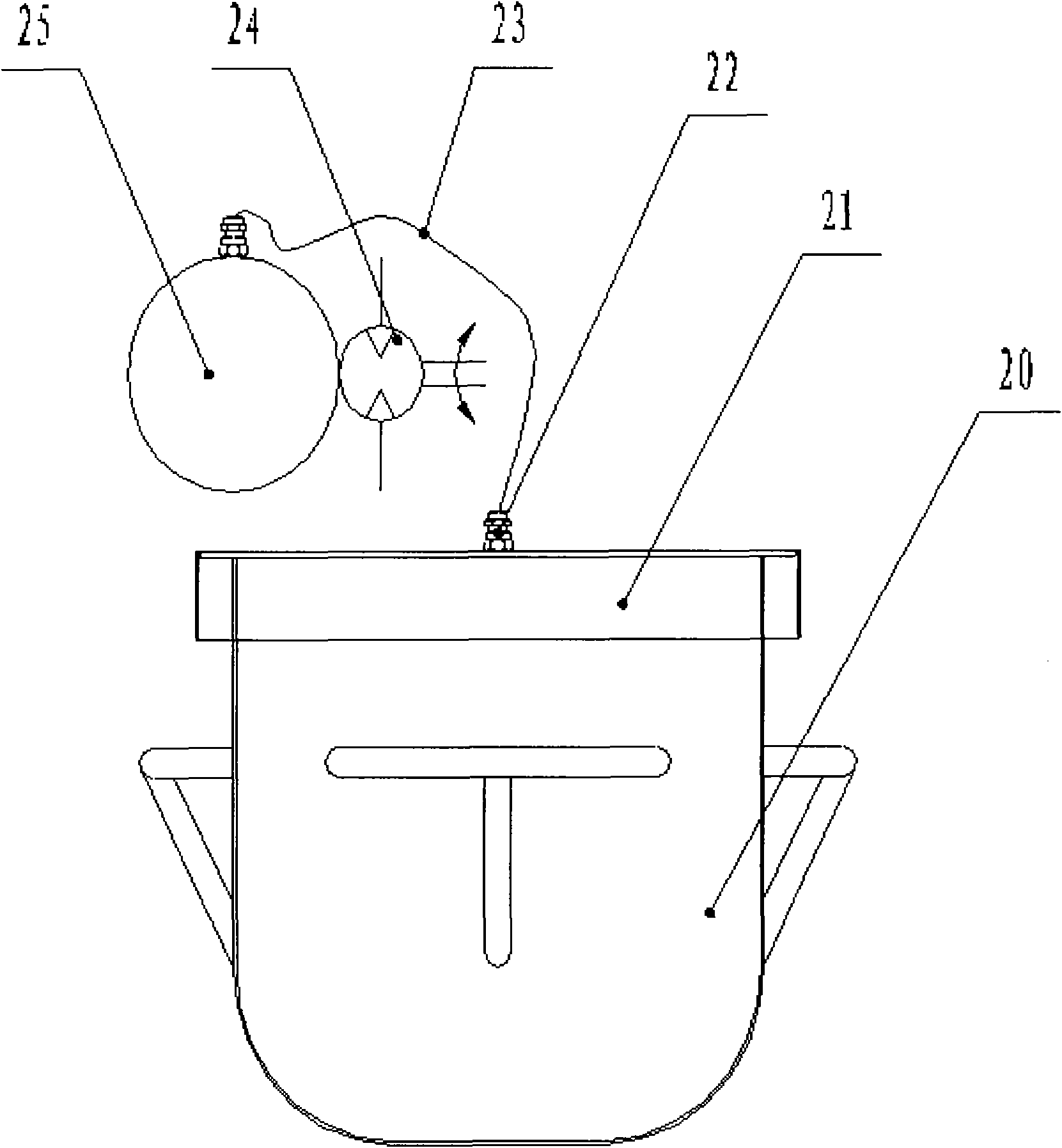

[0023] Accompanying drawing is a kind of specific embodiment of the present invention.

[0024] Cotton and linen straw charcoal combustion furnace includes a furnace body 12 provided with a combustion chamber 8, the upper end of the combustion chamber 8 provided with a feed port 7 is connected to a combustion chamber 14, and the lower end is connected to a blanking chamber 10; the outer layer of the combustion chamber 8 is wrapped with A water jacket 13, the water jacket 13 is provided with a water inlet port 16 and a water outlet port 18 respectively connected to the heating equipment 17; a chimney 15 is provided at the top of the furnace body 12; an automatic discharge door 11 is installed at the bottom of the blanking chamber 10; The side of the combustion chamber 14 is provided with a secondary oxygen inlet 9; the chimney 15 is provided with a smoke filter device 19 .

[0025] Put cotton and hemp stalks into the combustion chamber 8 through the feed port 7 for combustion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com