Energy-saving repairing engine lubricating oil

A lubricating oil and engine technology, which is applied in the field of lubricating oil, can solve the problems of poor repair function, poor energy saving and emission reduction effect, poor anti-wear performance, etc., and achieve the effects of repairing mechanical wear, good friction reduction, and improving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

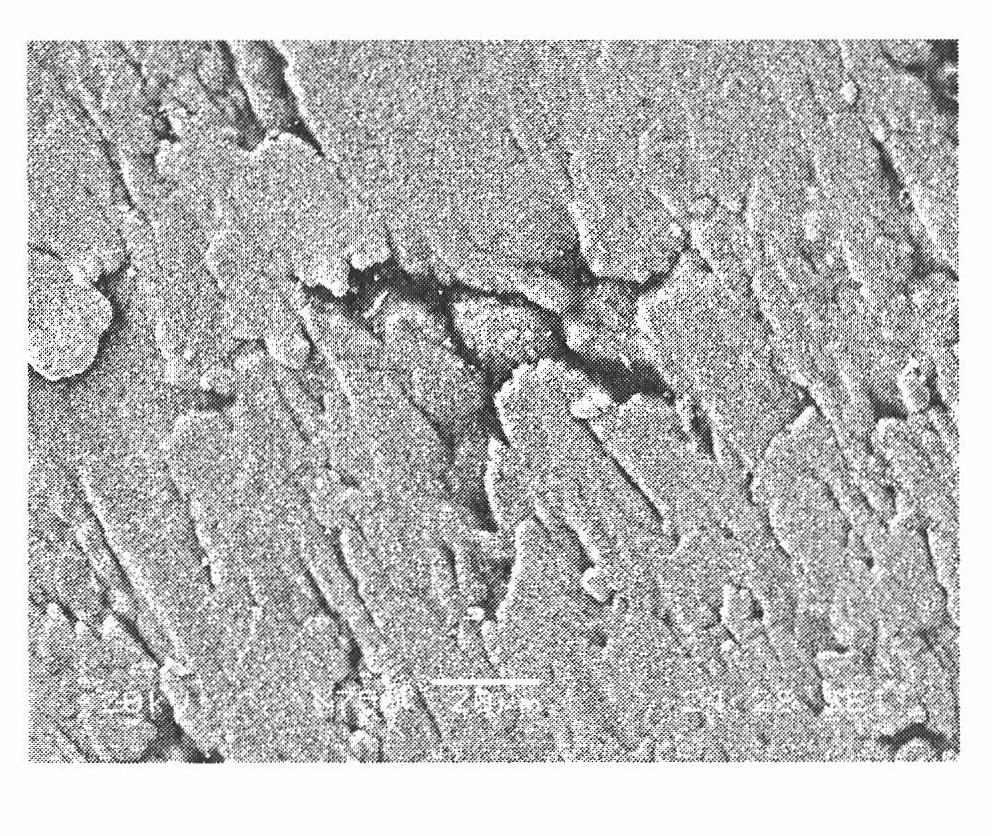

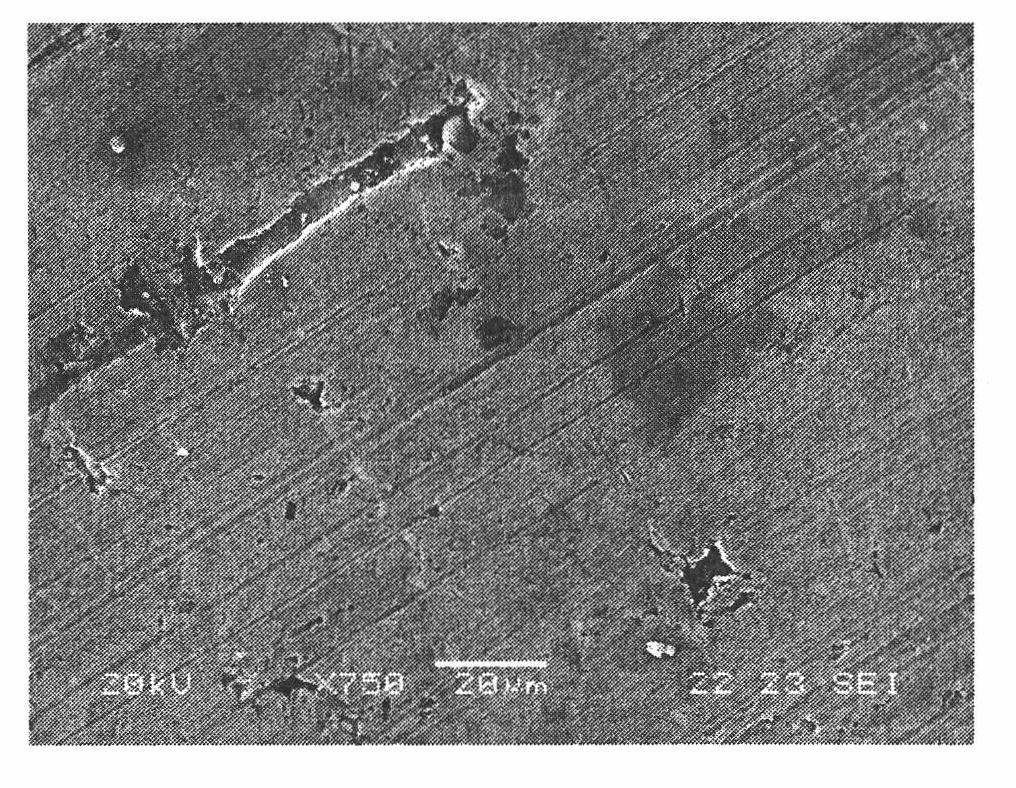

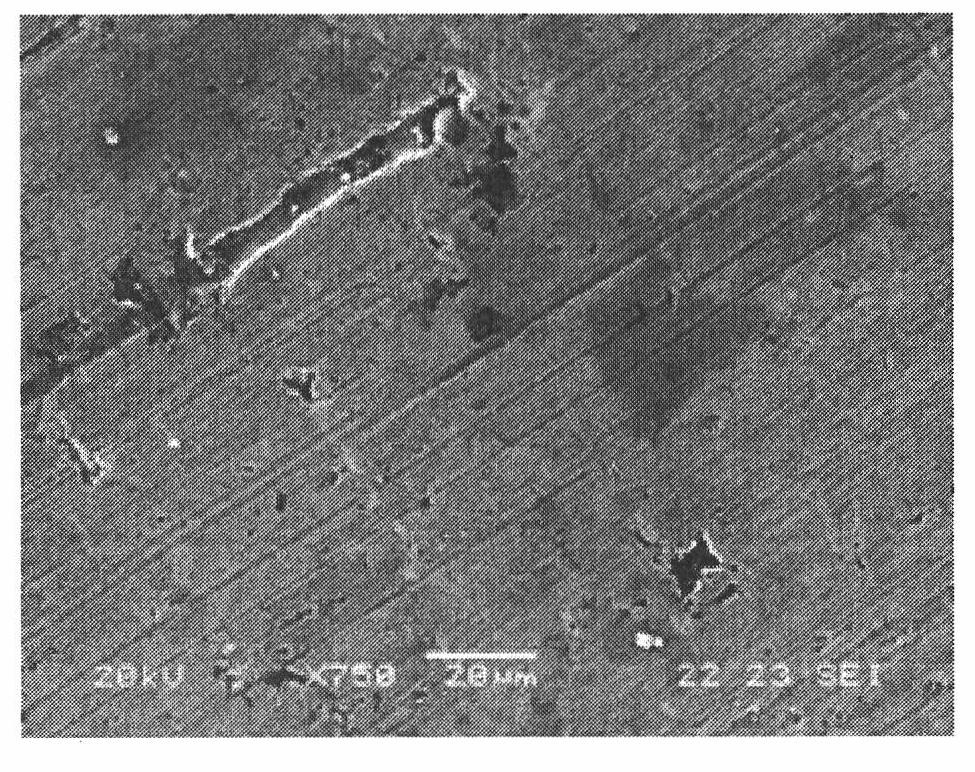

Image

Examples

Embodiment Construction

[0033] An energy-saving and repairing engine lubricating oil according to the present invention, the content of each component in the lubricating oil (in weight percent) is:

[0034] a. Base oil 70-95%

[0035] b. Detergent 1-8%

[0036] c. Dispersant 1-8%

[0037] d. Viscosity index improver 0.5-9%

[0038] e. Anti-foaming agent: 1-70ppm

[0039] f. pour point depressant: 0.1-1%

[0040] g. Antioxidant: 0.1-1%

[0041] h. Oil-soluble nano lanthanum trifluoride 0.1-5%

[0042] i. Oil-soluble nano copper (alloy) 0.1-5%

[0043] The base oil is a hydrogenated base oil belonging to API, II and III, and the content of each component in the tertiary hydrogenated base oil (in weight percent) is:

[0044] 100N 5-20%

[0045] 150N 30-50%

[0046] 500N 20-40%

[0047] 150BS 5-10%

[0048] The detergent is petroleum sulfonate, synthetic calcium sulfonate or calcium alkyl salicylate, and the dispersant is monosuccinimide or bis-succinimide. The viscosity index improver is one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com