Method for preparing biomass straw biogas and adopted devices thereof

A technology for biomass straw and biogas, which is applied in biochemical equipment and methods, biochemical cleaning devices, enzymology/microbiology devices, etc. problems, to achieve the effect of high energy input and output efficiency, high temperature input energy, and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

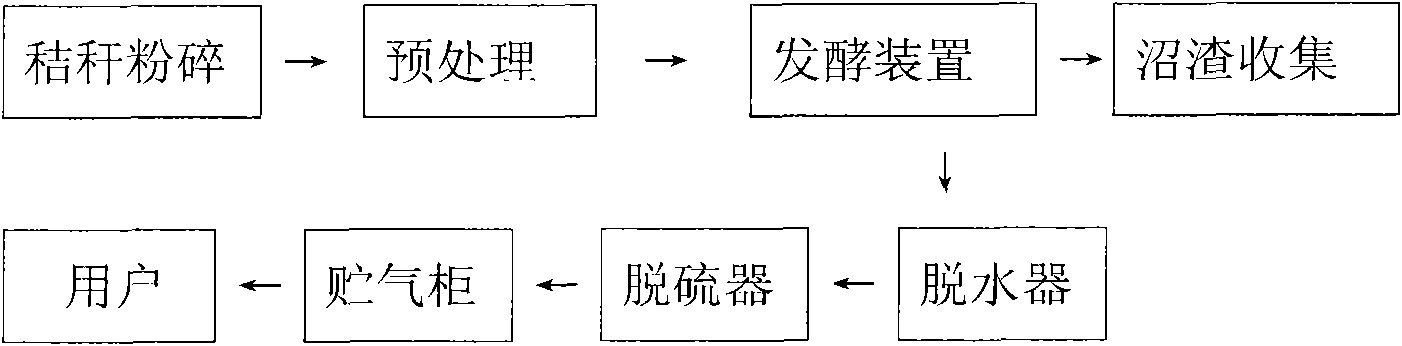

[0037] see figure 1 , the method for preparing biomass straw biogas can be implemented in sequence as follows:

[0038] (1) Pretreating the biomass straw material;

[0039] (2) Fermenting the material produced in step (1);

[0040] (3) Dehydration treatment of primary gas;

[0041] (4) Send the gas generated in step (3) into the gas holder.

[0042] In the present invention, desulfurization treatment may be continued after the step (3) is completed.

[0043] In the present invention, in the above step (1), the biomass straw material is pulverized so that the particle diameter reaches 2.5 cm and the pH value reaches 7.

[0044] In the present invention, the temperature of material fermentation in step (2) is 35°C.

[0045] In the present invention, the temperature of material fermentation in step (2) may also be 55°C.

[0046] In the present invention, nitrogen source urea is added to the material in step (2).

Embodiment 2

[0048] see figure 1 , the method for preparing biomass straw biogas can be implemented in sequence as follows:

[0049] (1) Pretreating the biomass straw material;

[0050] (2) Fermenting the material produced in step (1);

[0051] (3) Dehydration treatment of primary gas;

[0052] (4) Send the gas generated in step (3) into the gas holder.

[0053] In the present invention, the desulfurization treatment is carried out continuously after the step (3) is completed.

[0054] In the present invention, in the step (1), the biomass straw material is pulverized so that the particle diameter reaches 2 centimeters and the pH value reaches 6.8.

[0055] In the present invention, the temperature of material fermentation in step (2) is 30°C.

[0056] In the present invention, the temperature of material fermentation in step (2) is 50°C.

[0057] In the present invention, nitrogen source ammonium bicarbonate is added to the material in step (2).

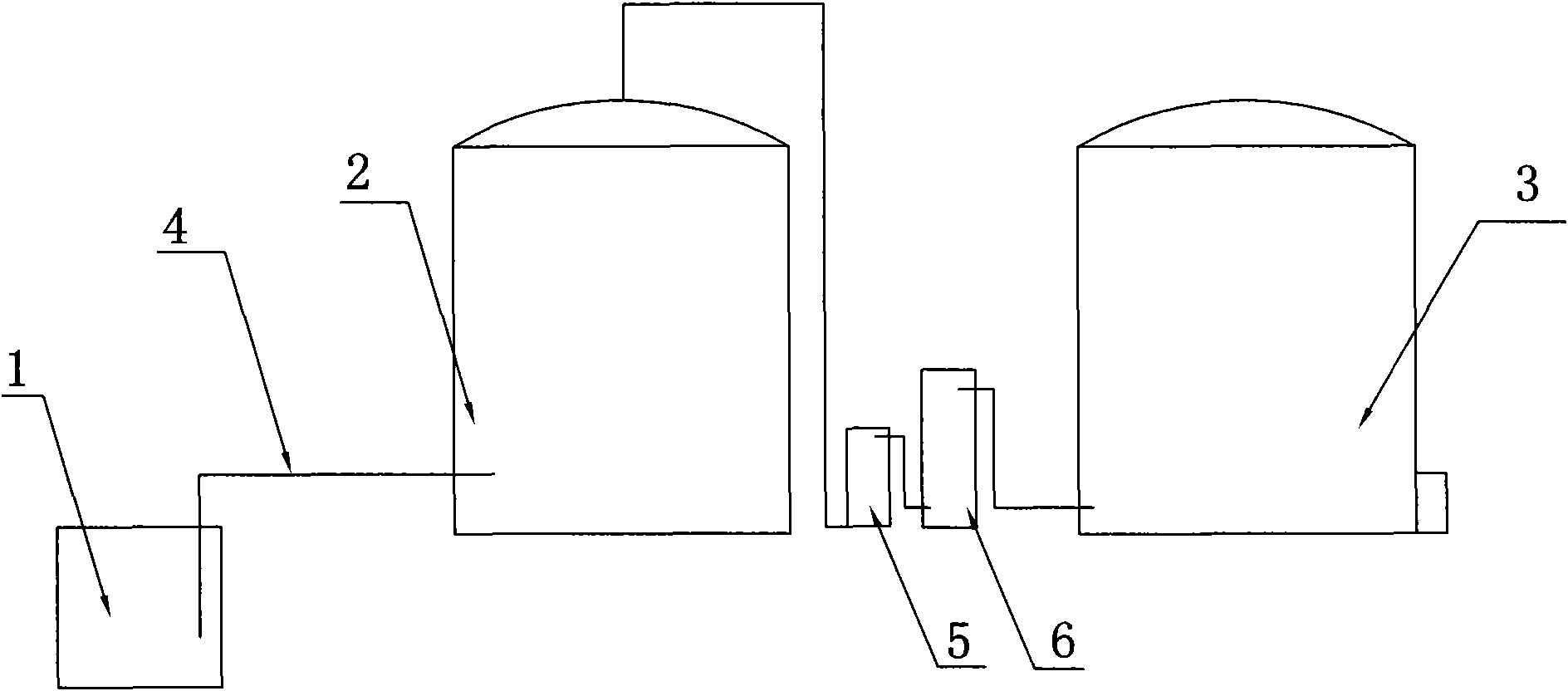

[0058] see figure 2 , the device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com