Tough antiflaming magnesium alloy and preparation method thereof

A magnesium alloy, strong and tough technology, applied in the field of strong and tough flame-retardant magnesium alloy materials and their preparation, can solve the problems of low, polluted mechanical properties of the alloy, poor effect, etc., and achieves cost reduction, excellent mechanical properties, and rich rare earth resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

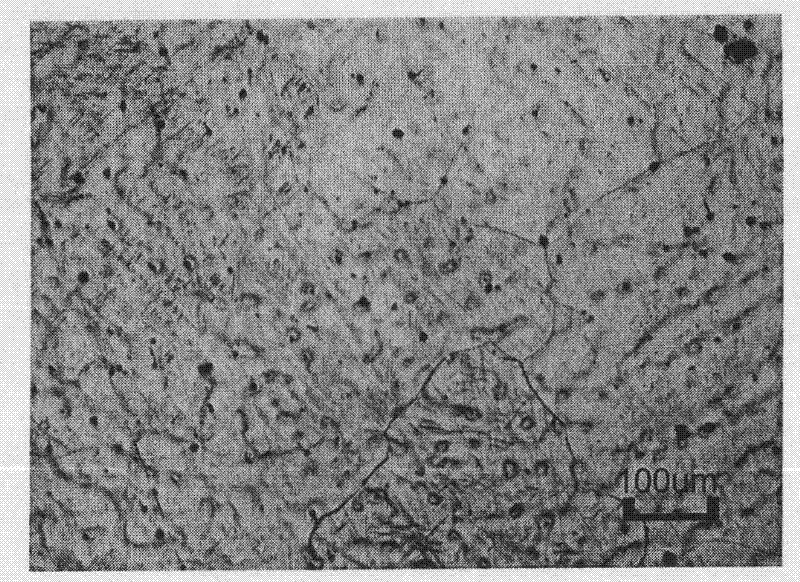

Embodiment 1

[0018] Embodiment 1: Get 1010 grams of commercially pure Mg (99.99wt.%) (calculated by 20% burning loss), get 217 grams of Mg-30wt.% Gd master alloy (calculated by 30% burning loss), get Mg-20wt. 33 grams of % Er master alloy (calculated on the basis of 30% burning loss), and 10 grams of Mg-30wt.% Zr master alloy (calculated on the basis of 20% burning loss). Its preparation process is:

[0019] (1) Clean up the melting tools and crucible, brush the paint, and take out the crucible after preheating to 600°C;

[0020] (2) Add pre-dried commercially pure Mg into the crucible, in order to prevent oxidation in N 2 Gas and SF 6 Heating under the protection of mixed gas (wherein SF 6 Volume fraction is 1%), warming up to 780 ℃;

[0021] (3) Skim off the scum after the furnace charge is completely melted, add Mg-Gd and Mg-Er master alloys and stir for 3 minutes after they are completely melted, then add Mg-Zr master alloys and stir for 3 minutes after they are completely melted, ...

Embodiment 2

[0026] Embodiment 2: Get 990 grams of commercially pure Mg (99.99wt.%) (calculated by 20% burning loss), get 217 grams of Mg-30wt.% Gd master alloy (calculated by 30% burning loss), get Mg-20wt. 65 grams of % Er master alloy (calculated on the basis of 30% burning loss), and 10 grams of Mg-30wt.% Mn master alloy (calculated on the basis of 20% burning loss). Its preparation process is:

[0027] (1) Clean up the melting tools and crucible, brush the paint, and take out the crucible after preheating to 600°C;

[0028] (2) Add pre-dried commercially pure Mg into the crucible, in order to prevent oxidation in N 2 Gas and SF 6 Heating under the protection of mixed gas (wherein SF 6 Volume fraction is 1%), warming up to 780 ℃;

[0029] (3) Skim off the scum after the furnace charge is completely melted, add Mg-Gd and Mg-Er master alloy and stir for 3 minutes after it is completely melted, then add Mg-Mn master alloy and stir for 3 minutes after it is completely melted, and keep ...

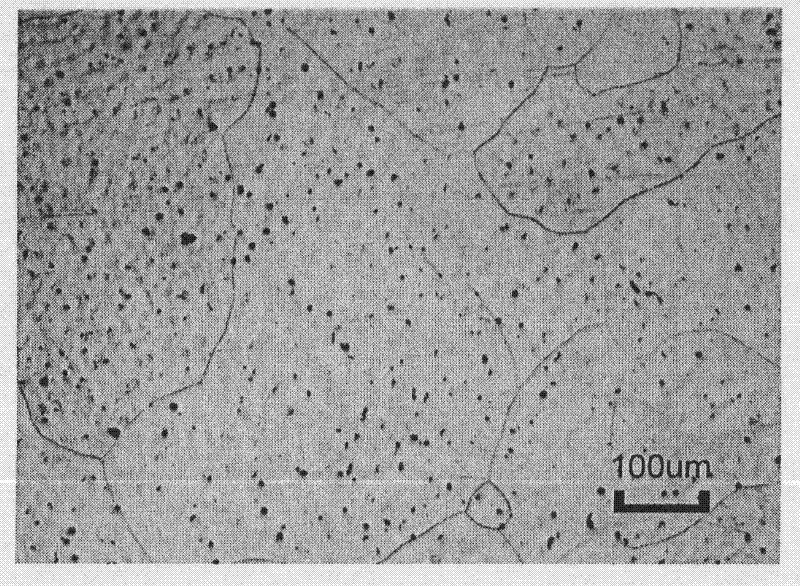

Embodiment 3

[0034] Embodiment 3: Get 960 grams of commercially pure Mg (99.99wt.%) (calculated by 20% burning loss), get 217 grams of Mg-30wt.%Gd master alloy (calculated by 30% burning loss), get Mg-20wt. 65 grams of % Er master alloy (calculated on the basis of 30% burning loss), and 40 grams of Mg-30wt.% Mn master alloy (calculated on the basis of 20% burning loss). Its preparation process is:

[0035] (1) Clean up the melting tools and crucible, brush the paint, and take out the crucible after preheating to 600°C;

[0036] (2) Add pre-dried commercially pure Mg into the crucible, in order to prevent oxidation in N 2 Gas and SF 6 Heating under the protection of mixed gas (wherein SF 6 Volume fraction is 1%), warming up to 780 ℃;

[0037] (3) Skim off the scum after the furnace charge is completely melted, add Mg-Gd and Mg-Er master alloy and stir for 3 minutes after it is completely melted, then add Mg-Mn master alloy and stir for 3 minutes after it is completely melted, and keep i...

PUM

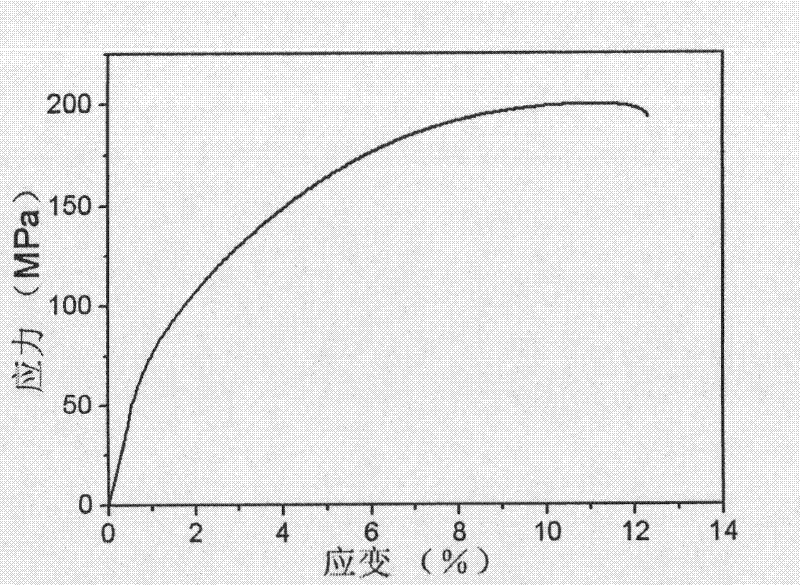

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com