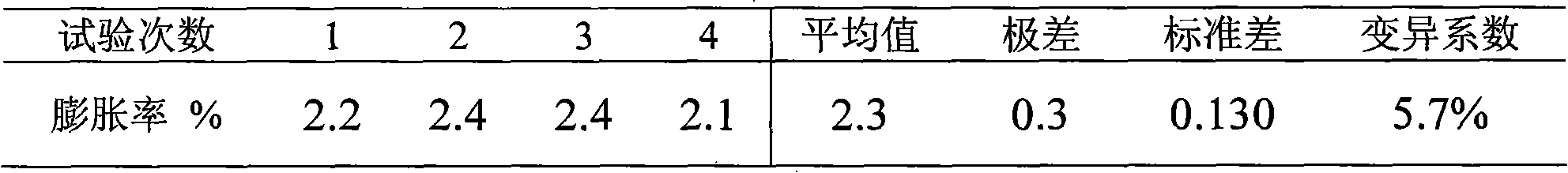

Test method for expansion ratio of cement emulsified asphalt mortar

A detection method and expansion rate technology, applied in the field of material property detection, can solve the problems of inaccurate measurement, cumbersome operation, large coefficient of variation, etc., and achieve the effect of solving difficult operation, avoiding errors and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method for detecting the expansion rate of cement emulsified asphalt mortar, comprising the following steps:

[0021] (1) Stand the measuring cylinder (or other container) on a level surface without shock and vibration;

[0022] (2) Calibrate the volume V of the cylinder with water 0 and the volume V of the Erlenmeyer flask of 1000mL, measured several times, usually 3 times, and taking the average value;

[0023] (3) Pour the cement asphalt mortar into the Erlenmeyer flask, make the surface of the mortar flush with the neck of the bottle, and record the quality m of the mortar;

[0024] (4) by the volume of Erlenmeyer flask and the quality of adding mortar, the apparent density ρ of mortar can be obtained: apparent density ρ=mortar quality m / Erlenmeyer flask volume V in Erlenmeyer flask;

[0025] (5) Place the measuring cylinder on the balance to peel the mortar, inject the mortar in the Erlenmeyer flask into the measuring cylinder, stop adding when 250mL is added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com