Multilayer multi-line nature-imitated synchronous withering device used for processing black tea

A withering device and natural-imitation technology, which is applied in the field of multi-layer and multi-row natural imitation synchronous withering devices, can solve the problems of uneven water flow, large floor area, large beach cool floor area, etc., and achieve strong manual operability , small footprint and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the examples, but it does not constitute any limitation to the present invention.

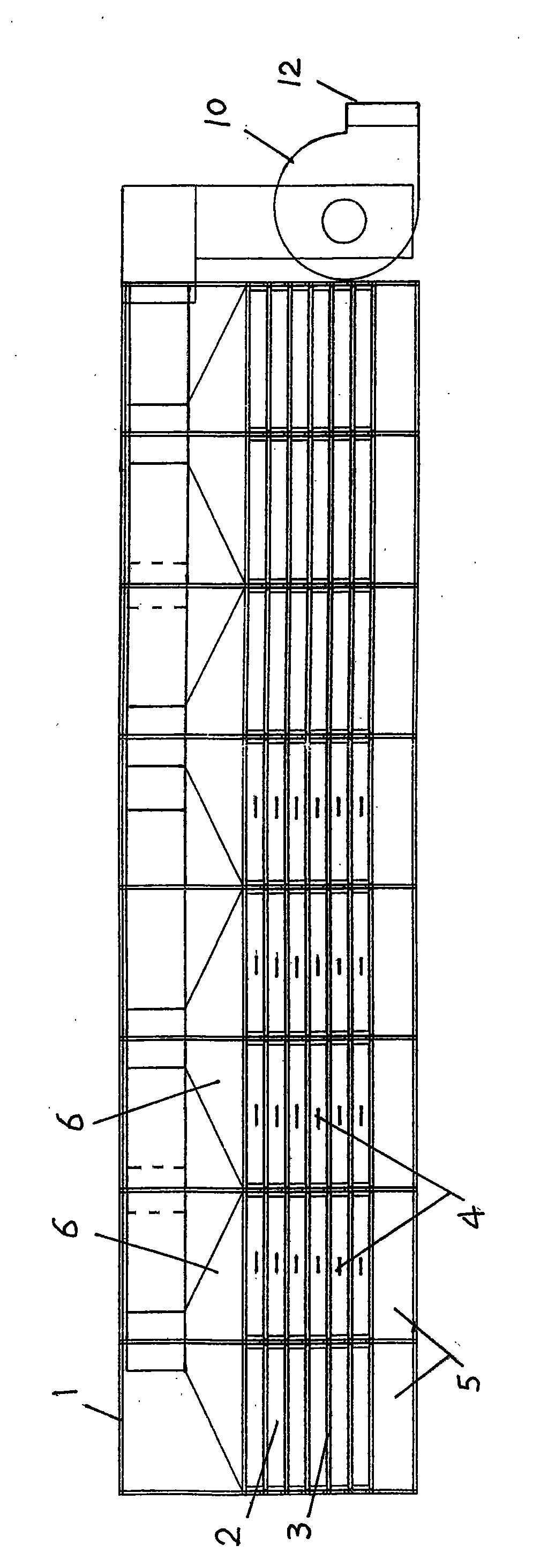

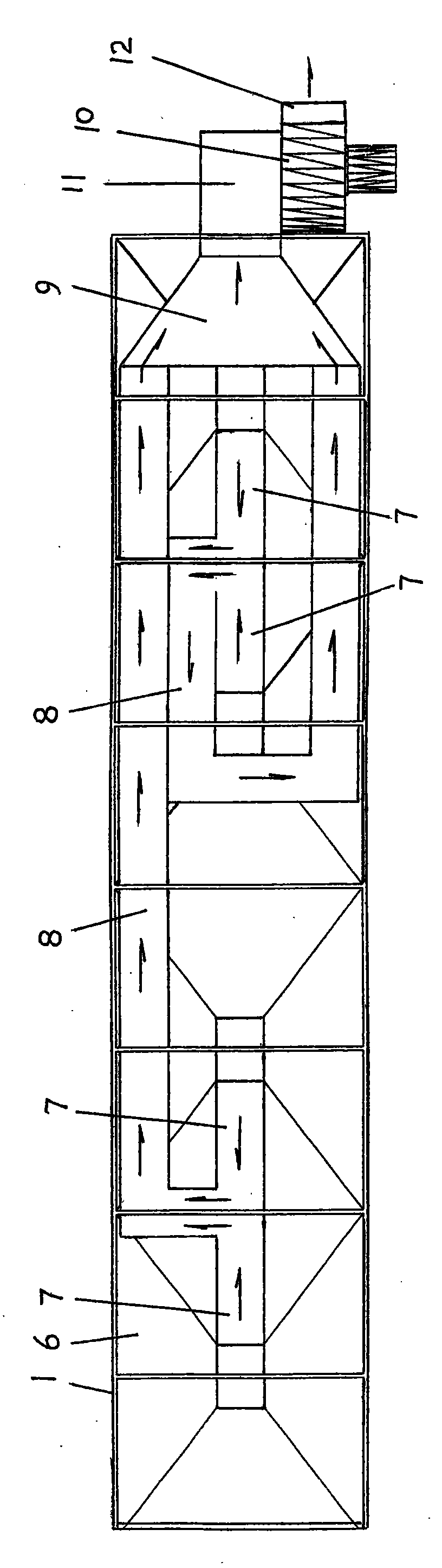

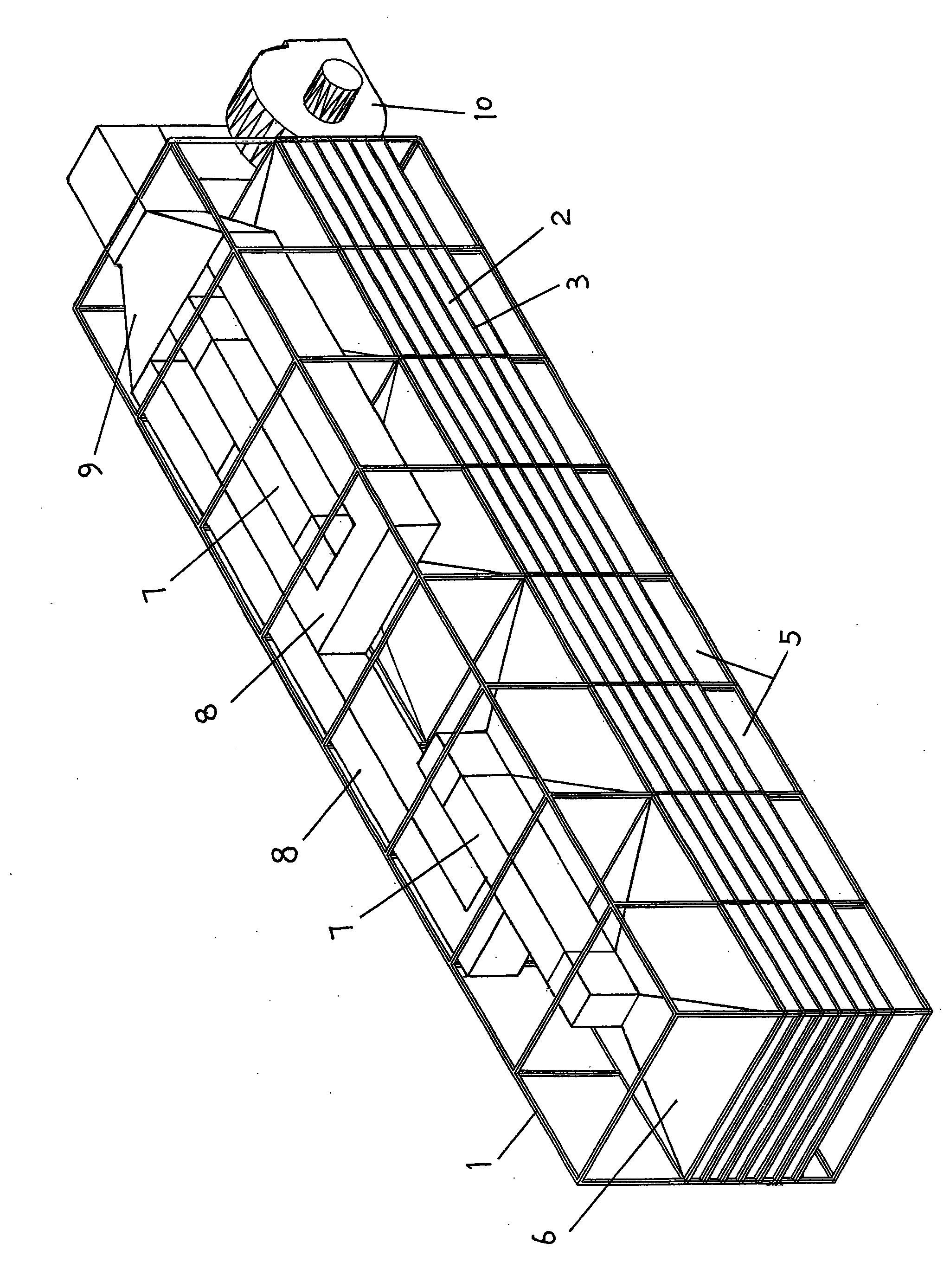

[0014] With reference to the accompanying drawings of the embodiment, it can be seen that the specific structure of the present invention includes: 1~withering frame (frame), 2~withering chamber (for multi-layer and multi-column structure), 3~drawer type shelving frame, 4~drawer type air sieve , 5~air inlet, 6~wet air collection cover, 7~(short) exhaust branch pipe, 8~(long) exhaust main pipe, 9~gathering chamber, 10~induced fan (centrifugal fan), 11 ~ air inlet of induced draft fan, 12 ~ air outlet of induced draft fan.

[0015] This natural imitation synchronous withering device comprises a frame 1 as a withering frame, an air inlet, an air outlet, and a draft fan 10, and is characterized in that: the frame is made of a multi-row cabinet type withering frame structure, In the middle part of the multi-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com