Polar coordinate numerical control woodworking basket milling machine

A polar coordinate and woodworking technology, applied in the field of polar coordinate CNC woodworking basket milling machine, can solve the problems of increased floor space, low processing efficiency, low processing efficiency, etc. high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

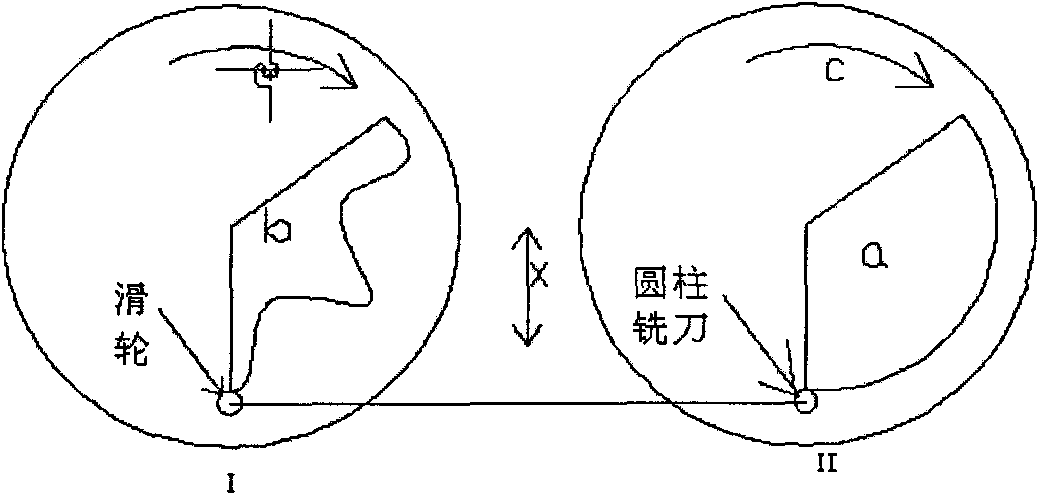

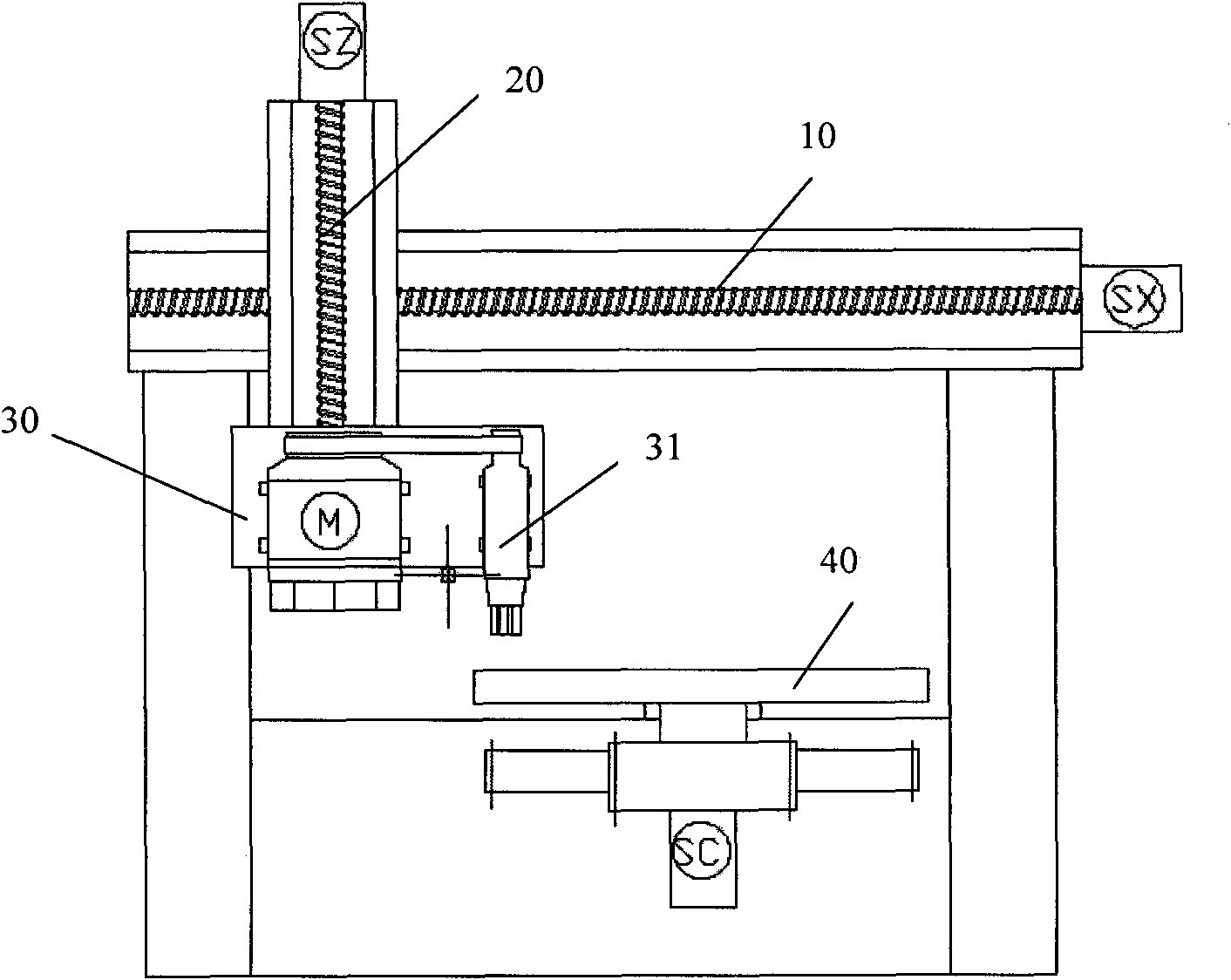

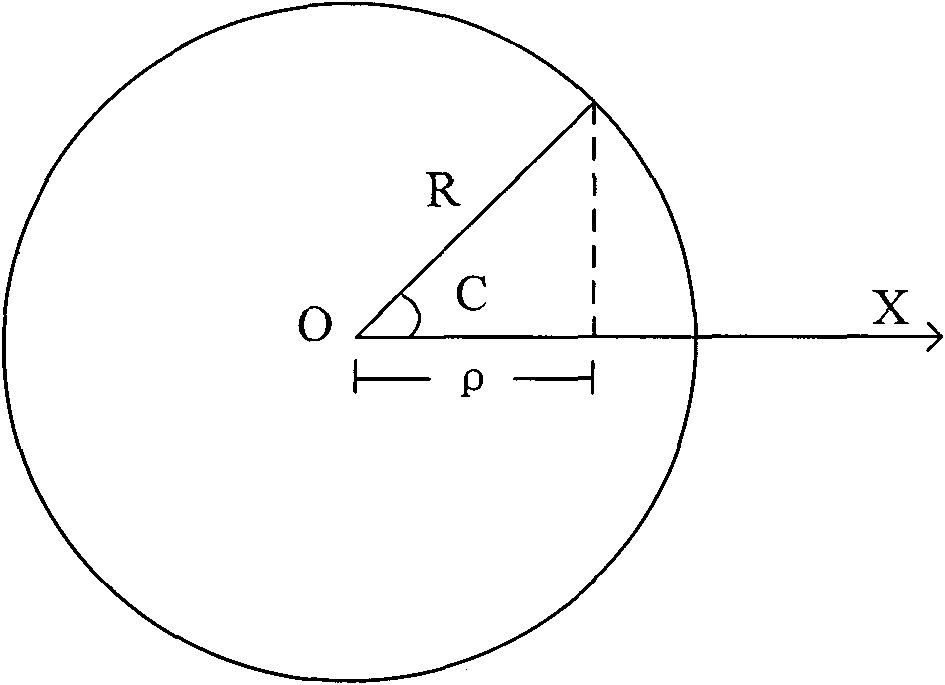

[0036] The polar coordinate numerical control woodworking basket milling machine of the present invention includes a mechanical mechanism and a numerical control mechanism for controlling the mechanical mechanism. Such as figure 2 As shown, it is a schematic structural view of the mechanical mechanism in the polar coordinate CNC woodworking basket milling machine of the present invention, and the mechanical mechanism includes the first screw mandrel 10, the second screw mandrel 20, the knife rest 30 and a circular workbench 40, and also includes :

[0037] The first servo motor SX that is arranged in the X-axis direction and drives the knife rest 30 to move horizontally in the X-axis direction by driving the first screw mandrel 10 to rotate; is arranged in the Z-axis direction and drives the knife rest by driving the second screw mandrel 20 to rotate 30 is the second servo motor SZ that moves vertically in the Z-axis direction; the third servo motor SC that drives the workta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com