Method for preparing waved stripe bamboo board stuck by side bamboo strips

A production method and wave-shaped technology, applied in the field of bamboo boards, can solve the problems of unsightly appearance, large processing volume, lack of forest resources, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

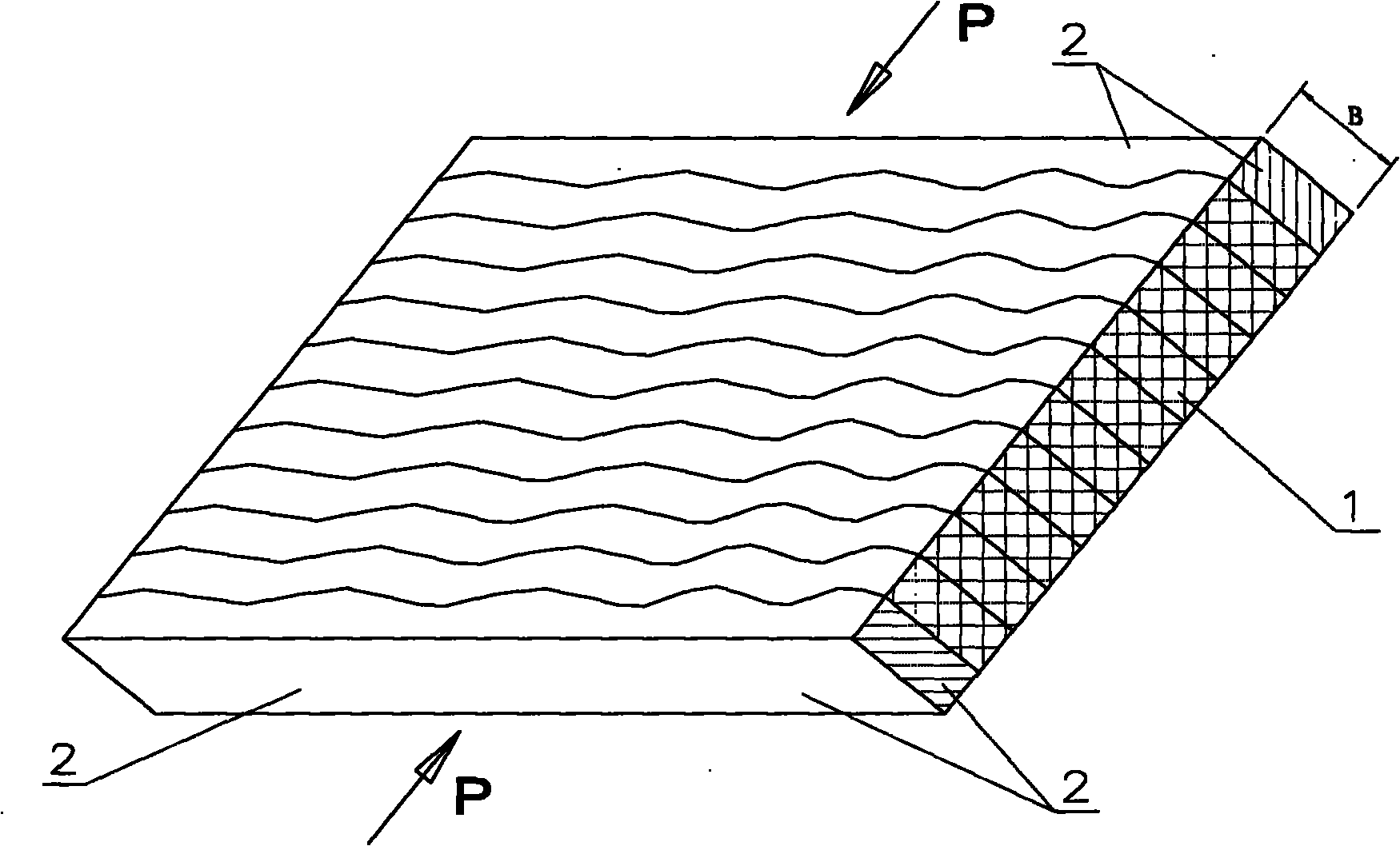

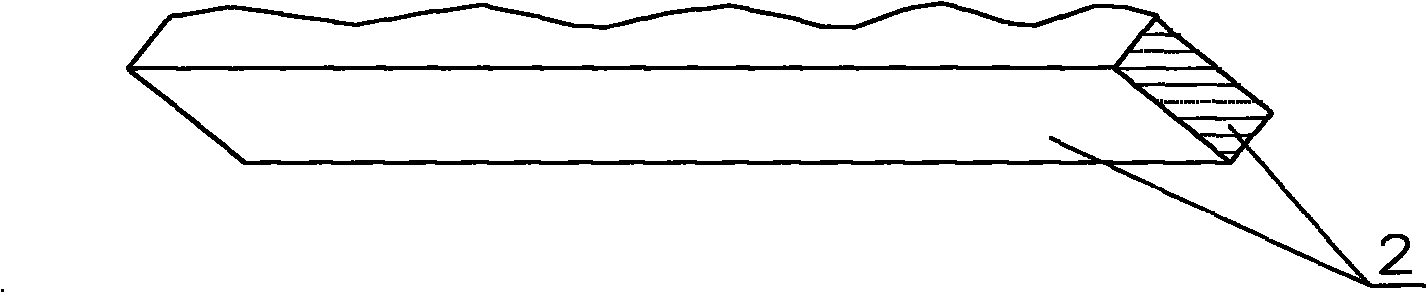

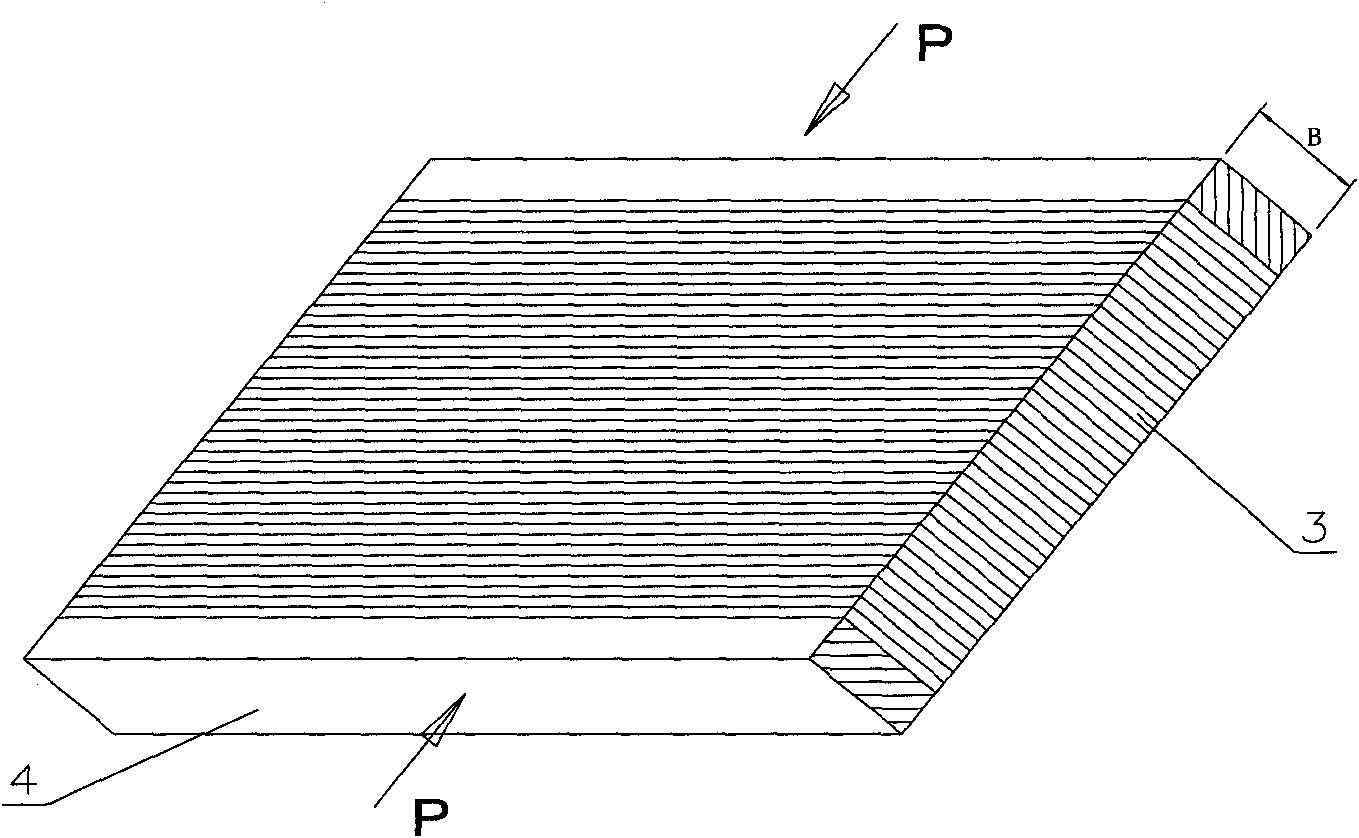

[0033] Example 1 as figure 1 , 2 , Shown in 4: a kind of manufacture method of the sticky bamboo plate of white side standing wavy bamboo strips, comprising:

[0034] Step 1, fresh bamboo pretreatment;

[0035] [1] Cut fresh bamboo into bamboo tubes of required length with a bamboo cutting machine;

[0036] [2] Split the bamboo tube into equal-width bamboo strip blanks with a bamboo splitter;

[0037] [3] Plane the blue outer surface, the yellow inner surface and the side surface of the bamboo strip blank with a bamboo planer to get a bamboo strip blank with a width B=10 mm.

[0038] Step two, bleaching;

[0039] [1] Put the green and yellowed bamboo blanks planed in step 1 into the bleaching tank, inject a 15% hydrogen peroxide aqueous solution, heat to 90°C, and continue for 20 hours; drain the bleached bamboo blanks After watering, send it to the drying room to dry until the moisture content is less than 11%.

[0040] Step 3, set the width and thickness, dip and dry;...

Embodiment 2

[0050] Example 2 as figure 1 , 2 , Shown in 4: a kind of manufacture method of the sticky bamboo plate of brown side standing wavy bamboo strips, comprising:

[0051] Step 1, fresh bamboo pretreatment,

[0052] [1] Cut fresh bamboo into bamboo tubes of required length with a bamboo cutting machine;

[0053] [2] Split the bamboo tube into equal-width bamboo strip blanks with a bamboo splitter;

[0054] [3] Plane the blue outer surface, the yellow inner surface and the side of the bamboo strip blank with a bamboo planer and a yellow scraper to get a bamboo strip blank with a width B=15 mm.

[0055] Step 2, vulcanization and drying;

[0056] [1] Put the green and yellowed bamboo blanks in step 1 into the blanching tank, boil them in boiling water for 4 hours, put the boiled bamboo blanks in a drying room and dry them until the water content is less than 15% ; Then put the boiled and dried bamboo strips into a vulcanization tank, inject steam with a temperature of 70-150 ° C...

Embodiment 3

[0068] Example 3 as figure 1 , 2 , Shown in 4: a kind of manufacture method of the sticky bamboo board material of a kind of colored side standing wavy bamboo strips, comprising:

[0069] Step 1, fresh bamboo pretreatment;

[0070] [1] Cut fresh bamboo into bamboo tubes of required length with a bamboo cutting machine;

[0071] [2] Split the bamboo tube into equal-width bamboo strip blanks with a bamboo splitter;

[0072] [3] Plane the blue outer surface, the yellow inner surface and the side of the bamboo strip blank with a bamboo planer to get a bamboo strip blank with a width B=20 mm.

[0073] Step 2, dyeing;

[0074] [1] Put the green and yellowed bamboo blanks in step 1 into the dyeing pool, boil them in boiling water for 5 hours, put the boiled bamboo blanks in a drying room and dry until the water content is less than 15%;

[0075] [2] After draining the water on the surface of the dyed bamboo blanks, put them in a drying room and dry them until the moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com