Self-propelled aerial working platform vehicle chassis

A high-altitude work platform and vehicle chassis technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of reduced driving force, low work efficiency, complex structure, etc., and achieve improved stability, fast response speed, and high control precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

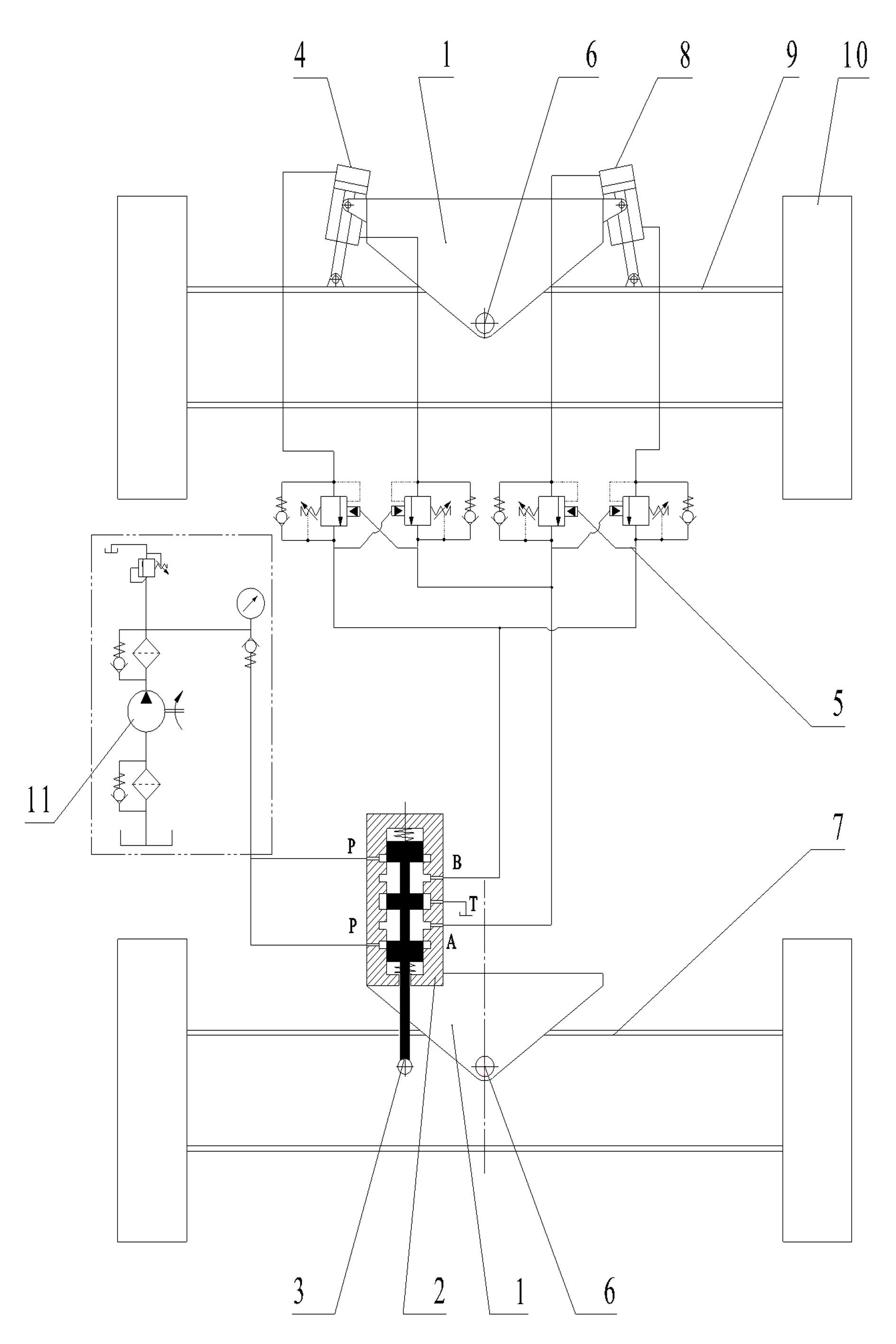

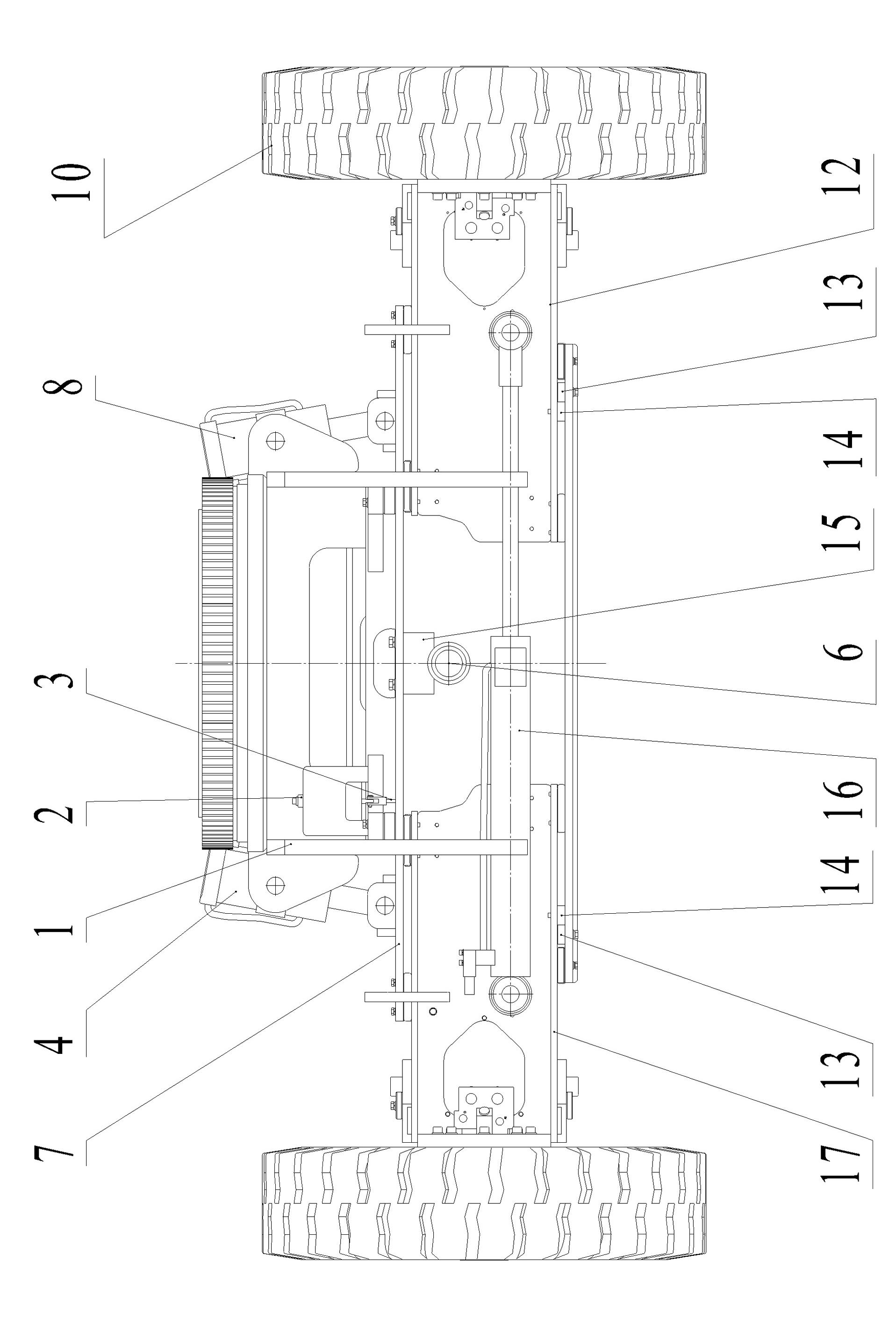

[0023] like figure 1 As shown, a vehicle frame 1 is provided, and the vehicle frame 1 is respectively hinged with the front axle 9 and the rear axle 7 through the chassis main shaft 6, and the rear axle 7 is free to swing around the chassis main shaft 6 within a set range, so that the rear axle 7 left and right tires 10 Always in contact with the ground, the front axle 9 swings around the chassis main shaft 6 driven by the left servo hydraulic cylinder 4 and the right servo hydraulic cylinder 8, the cylinder body of the left servo hydraulic cylinder 4 is hinged with the vehicle frame 1, and the left servo hydraulic cylinder The piston rod of the cylinder 4 is hinged with the front axle 9, the cylinder body of the right follow-up hydraulic cylinder 8 is hinged with the vehicle frame 1, the piston rod of the right follow-up hydraulic cylinder 8 is hinged with the front axle 9, and the hydraulic energy source 11 uses constant pressure as four sides Two P ports of spool valve 2 su...

Embodiment 2

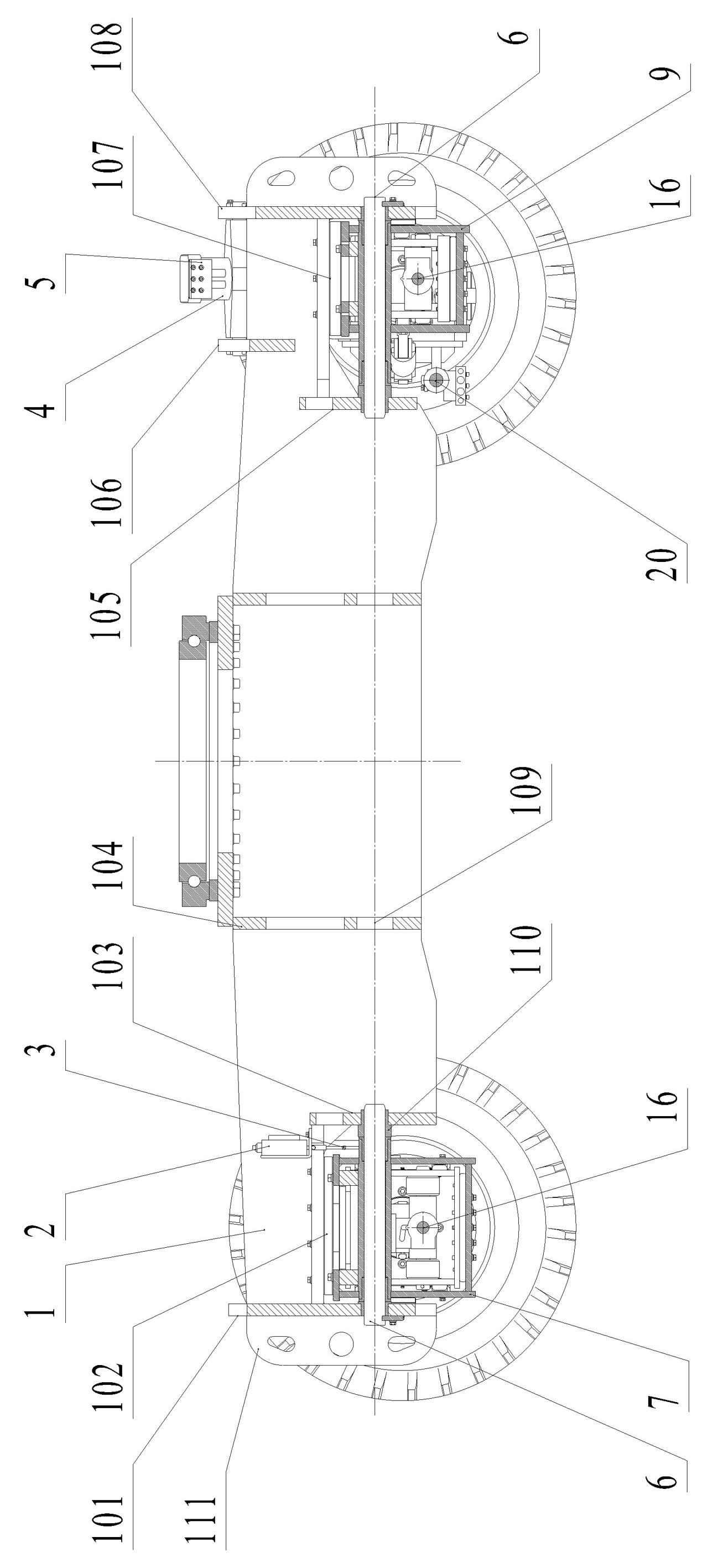

[0032] like Figure 5 As shown, a vehicle frame 1 is provided, and the vehicle frame 1 is respectively hinged with the front axle 9 and the rear axle 7 through the chassis main shaft 6, the rear axle 7 is free to swing around the chassis main shaft 6 within a set range, and the left and right tires 10 of the rear axle 7 are always In contact with the ground, the front axle 9 swings around the chassis main shaft 6 driven by the left servo hydraulic cylinder 4 and the right servo hydraulic cylinder 8, the cylinder body of the left servo hydraulic cylinder 4 is hinged with the vehicle frame 1, and the left servo hydraulic cylinder The piston rod of 4 is hinged with the front axle 9, the cylinder body of the right follow-up hydraulic cylinder 8 is hinged with the vehicle frame 1, the piston rod of the right follow-up hydraulic cylinder 8 is hinged with the front axle 9, and the hydraulic energy source 11 is a four-sided slide in a constant pressure manner. The P port of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com