Method and detecting system for detecting number of paper on liquid crystal flat glass production line

A glass production line and liquid crystal panel technology, applied in the field of detection systems, can solve problems affecting the normal operation of the production line, unstable paper output of the automatic paper loading system, and affecting normal packaging, etc., to achieve simple and fast detection methods and accurate and reliable detection results , the effect of resisting environmental interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

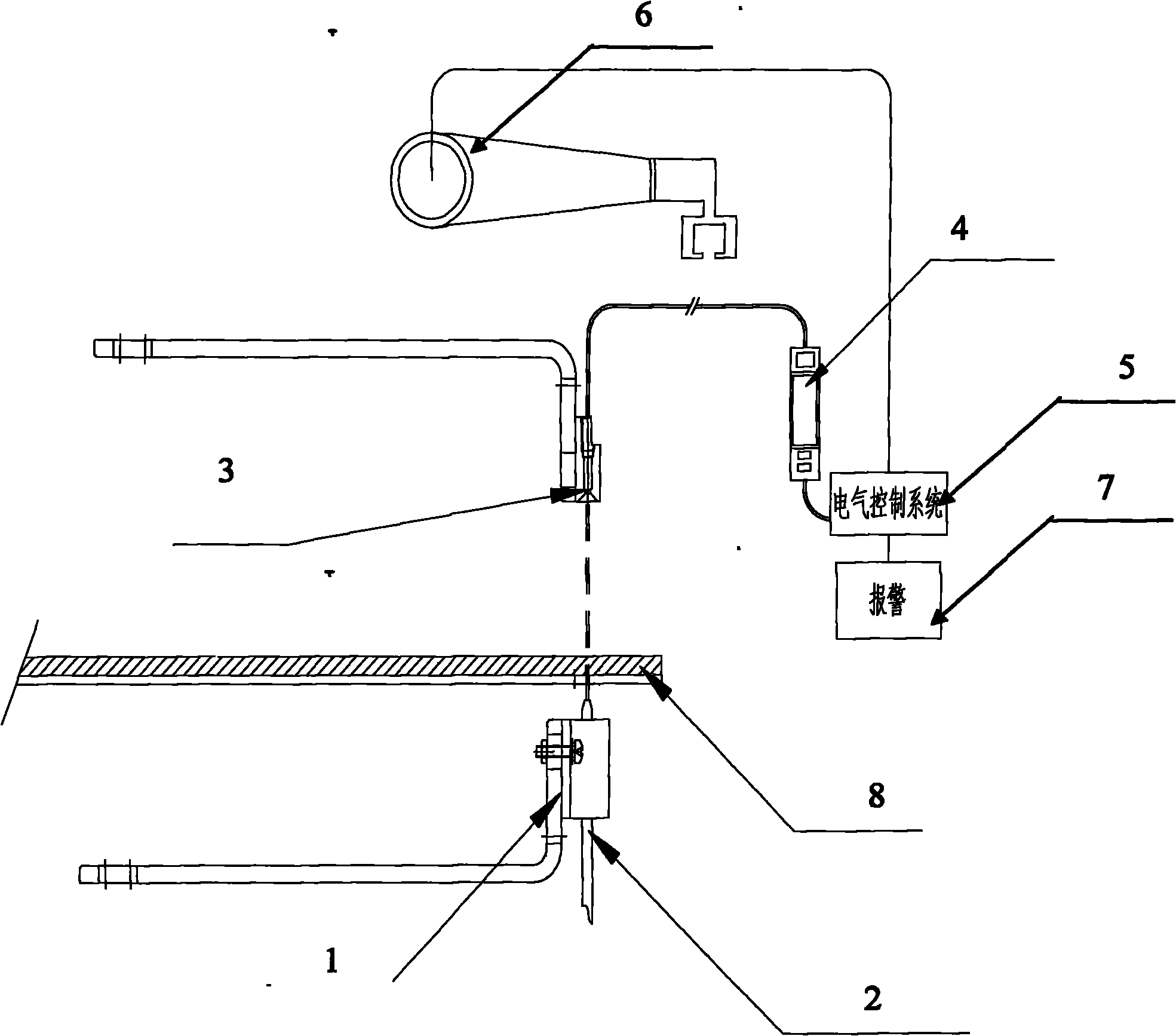

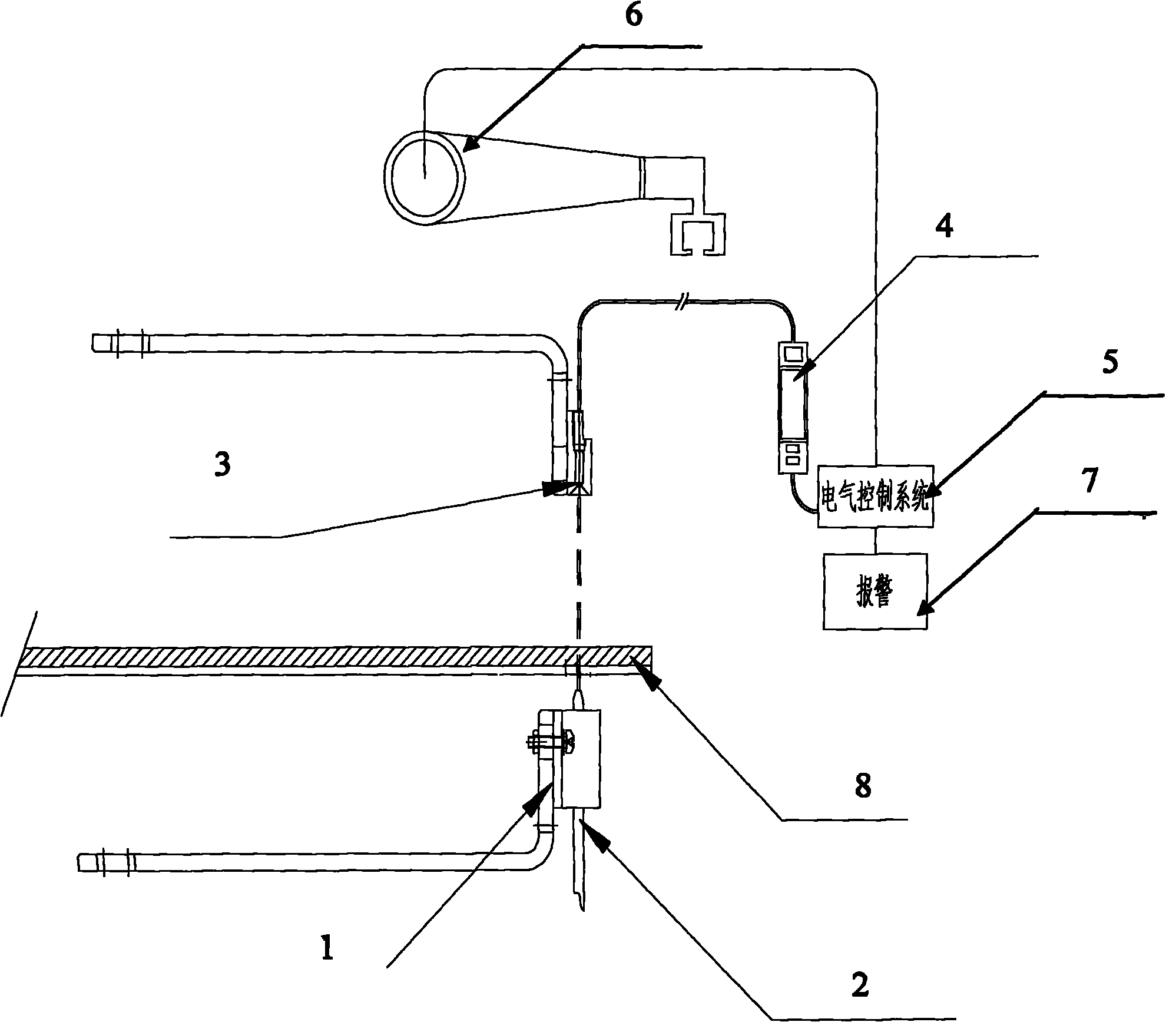

[0017] The mode step of the inventive method is as follows:

[0018] (1) A set of fiber optic sensors is required, that is, a fiber optic transmitter and a receiver, and the fiber optic sensor is connected to a fiber optic digital amplifier, and the fiber optic sensor is connected to the electrical control system;

[0019] (2) First install the fiber optic transmitter and receiver at a suitable position on the paper loading machine, and adjust the fiber optic transmitter and receiver to a suitable angle so that the light beam can pass through the paper vertically, and then fix the position of the fiber optic sensor;

[0020] (3) Connect the above optical fiber components with an optical fiber digital amplifier, and perform paperless optical fiber detection to see if it can work normally. Perform more than 4 times including 4 times at the above fixed position, for example, perform 6 times of direct beam detection and record it. The average value of signal strength X0;

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com