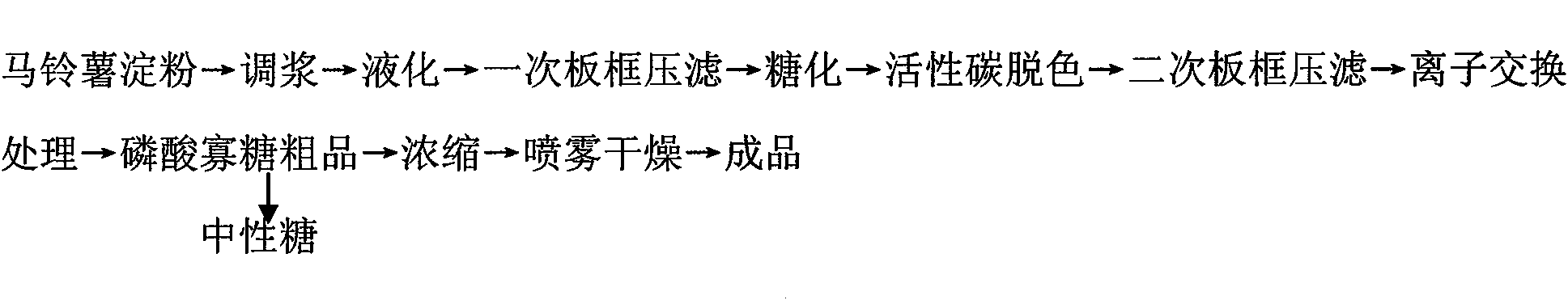

Method for preparing phosphoryl oligosaccharide by holoenzyme method

A technology for the preparation of oligophosphate oligosaccharides and enzymatic method, which is applied in fermentation and other fields, can solve the problems of detailed research on the production of oligophosphate oligosaccharides, and achieve the effects of less energy consumption, greater economic benefits, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1) Blending. First pour water into the batching tank, then slowly add 1 ton of raw starch under constant stirring, and use a Bomei meter for online detection until the slurry concentration is 10 o Be, then add 0.65kg CaCl 2 As an enzyme activity accelerator, use HCl and Na 2 CO 3 Adjust the slurry to a pH of 5.4.

[0020] 2) Liquefaction. After pumping the material into the jet liquefier, add a new type of high-temperature-resistant α-amylase to it, with an amount of 2,100,000u / ton of starch. In the jet, the slurry and the steam meet directly and fully, and the jet temperature is 110°C, and maintained for 4 ~8min, control the discharge temperature at 95~97°C, spray the liquefied feed liquid into the laminar flow tank, keep it at 95°C for 30min, and when the typical test reaction shows the true color of iodine, pass steam to kill the enzyme. The DE value of the liquefied material is 15% to 17%.

[0021] 3) Primary plate and frame filter press. When pressing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com