Aluminum-based composite material for composite pan bottom of stainless steel pan and preparation method thereof

A technology of aluminum matrix composite material and stainless steel pot is applied in the field of aluminum matrix composite material and its preparation, which can solve the problems of delamination and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

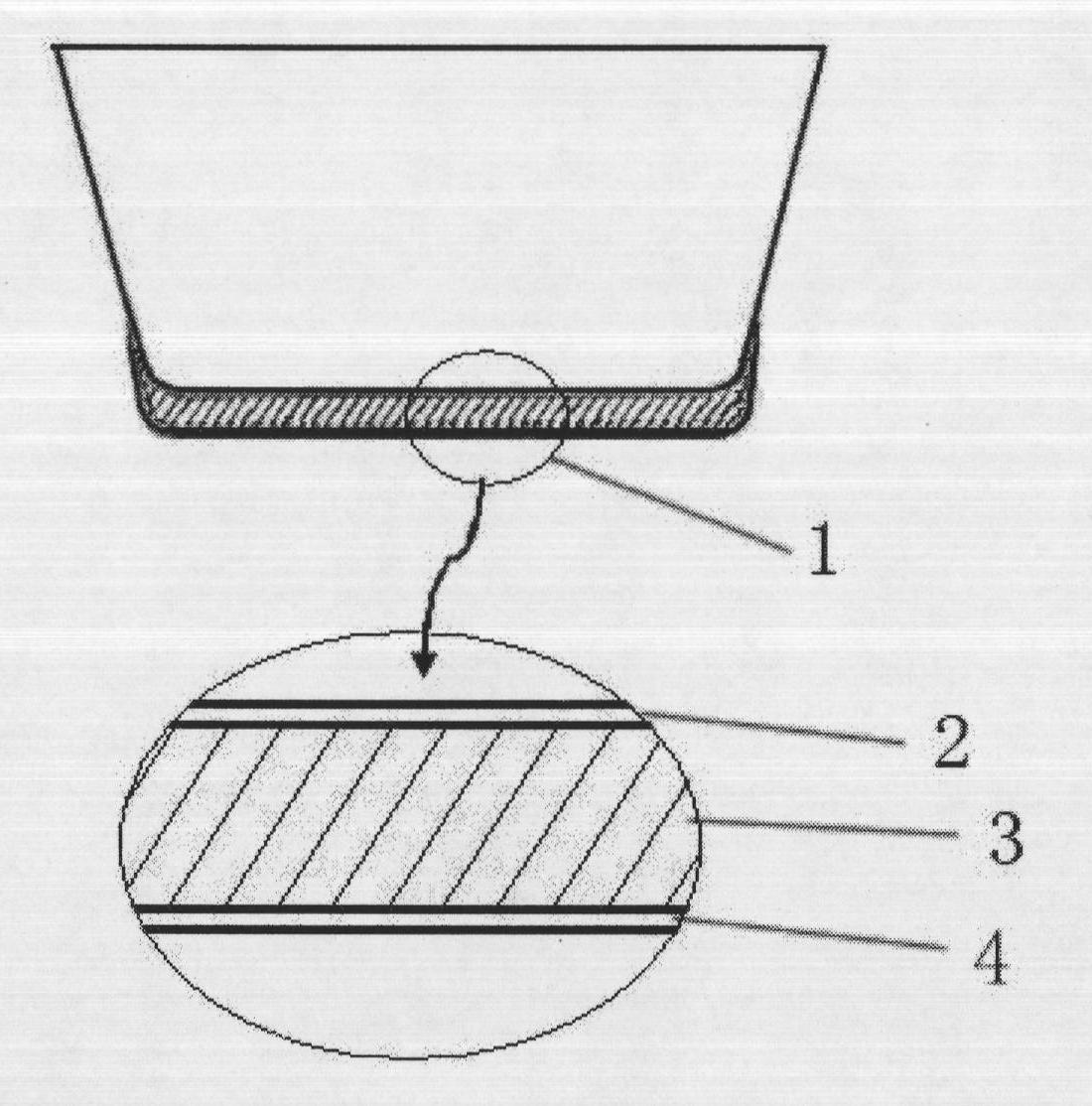

Image

Examples

Embodiment 1

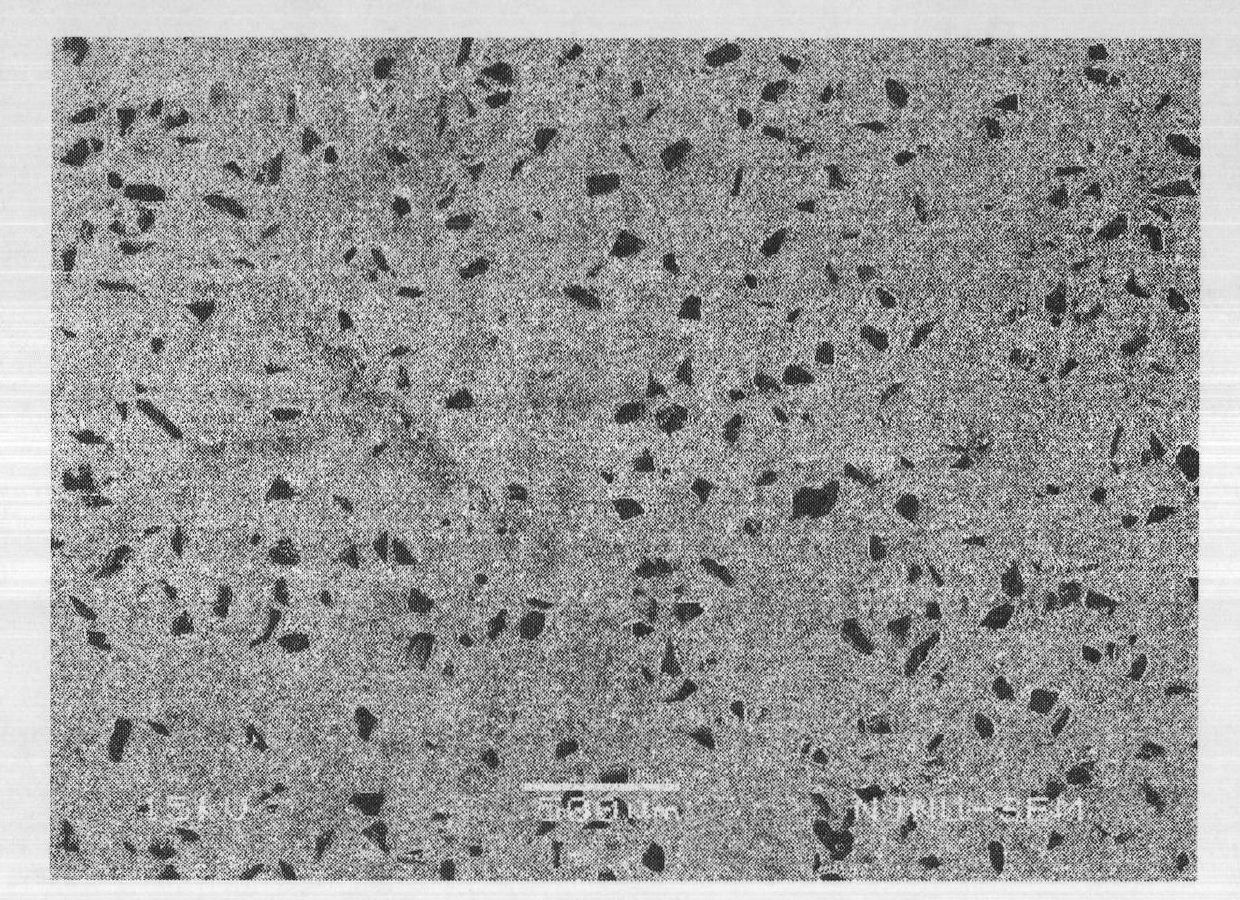

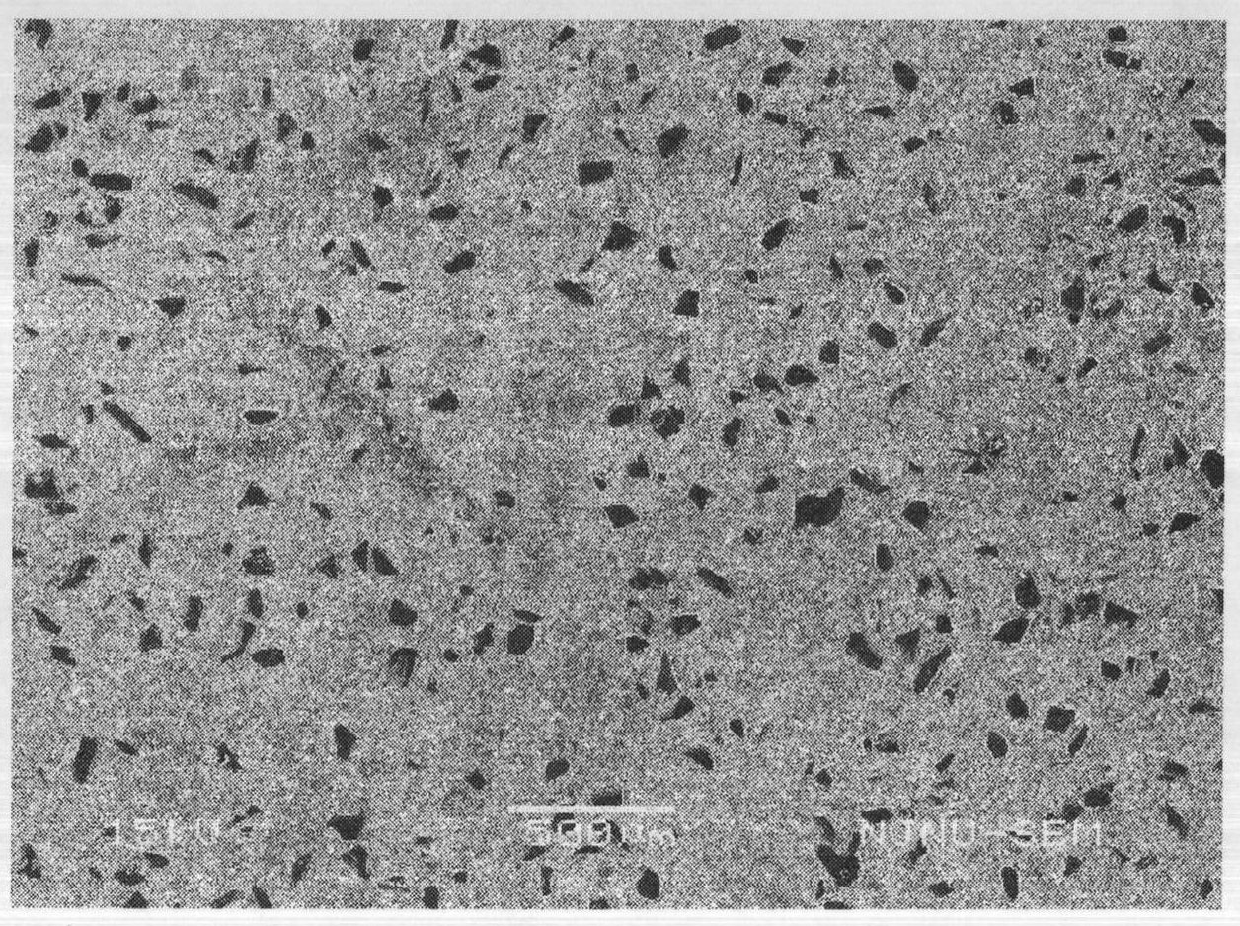

[0024] The particle-reinforced aluminum matrix composite material of this embodiment uses SiC particles as reinforcing particles, industrial pure aluminum (99.7%) as the matrix, the average particle size of SiC particles is 80 μm, and is uniformly distributed in the matrix, and the mass percentage of SiC particles is 10%.

[0025] The specific preparation method is as follows: Weigh 80μm SiC particles that account for 10% of the total weight of the substrate. The SiC particles are ultrasonically cleaned and calcined at 950°C for 4 hours, and then placed in a furnace to be preheated to 600°C. Preheated particles can be avoided on the one hand. It causes the temperature of the molten aluminum to decrease too quickly, and on the other hand, it can reduce the gas adsorption layer on the surface of the particles. Take about 1kg of pure aluminum ingot cut into small pieces and put it in a flat-bottomed carbon steel crucible with a diameter of 105mm (the crucible is sprayed with paint...

Embodiment 2

[0027] Based on Example 1, a SiC particle reinforced aluminum matrix composite material with a particle content of 20% of the total weight of the substrate was prepared, and 50 μm SiC particles accounting for 20% of the weight of the substrate were weighed. About 1kg of aluminum ingots were melted in a resistance furnace at 700°C Introduce Ar gas for refining for 15min, add Mg blocks that account for 3% of the mass of the aluminum matrix, and heat up to 730 ° C for stirring. The stirring parameters are: the diameter of the stirring paddle is 50 mm, the inclination angle of the paddle is 45°, the stirring speed is 700rpm, and the position of the stirring paddle can be at The height of 20% melt from the bottom of the crucible can be adjusted up and down to obtain better particle dispersion speed and dispersion quality. The stirring time is 45 minutes, and the temperature is gradually lowered to 720 °C for 1 minute to extract slag, and gravity casting is performed. The 20% SiC / Al ...

Embodiment 3

[0029] The particle-reinforced aluminum matrix composite material of this embodiment uses A356 aluminum alloy as the matrix, weighs about 1 kg of aluminum alloy block into the crucible, and melts it at 680 ° C and presses it into the Mg block accounting for 2% of the mass of the aluminum matrix with a bell jar to melt and keep stirring for 5 minutes. Homogenize, heat up to 730°C, pour in Ar gas for refining for 15min, add 0.06% Sr modifier and slowly stir for 10min, and stir after slag extraction. The stirring parameters are: stirring paddle diameter 50mm, paddle inclination angle 30°, stirring speed 780rpm , the position of the stirring blade is 20% of the height of the melt level at the bottom of the crucible, and the 50 μm Al, which accounts for 10% of the weight of the matrix after calcination at 900 °C for 2 hours, is uniformly added through the feeding funnel. 2 O 3 Particles, stirred for 30 minutes, cooled to 720 ℃ and cast into shape after slag extraction.

[0030]The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap