Reservoir and application mode thereof, vacuum thermal insulation board and check valve

A technology of vacuum insulation board and reservoir, applied in the fields of construction technology, building material technology and valve, can solve the problems of damage to the pool wall, unreliability, lack of effective measures for heat dissipation of large-capacity reservoirs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

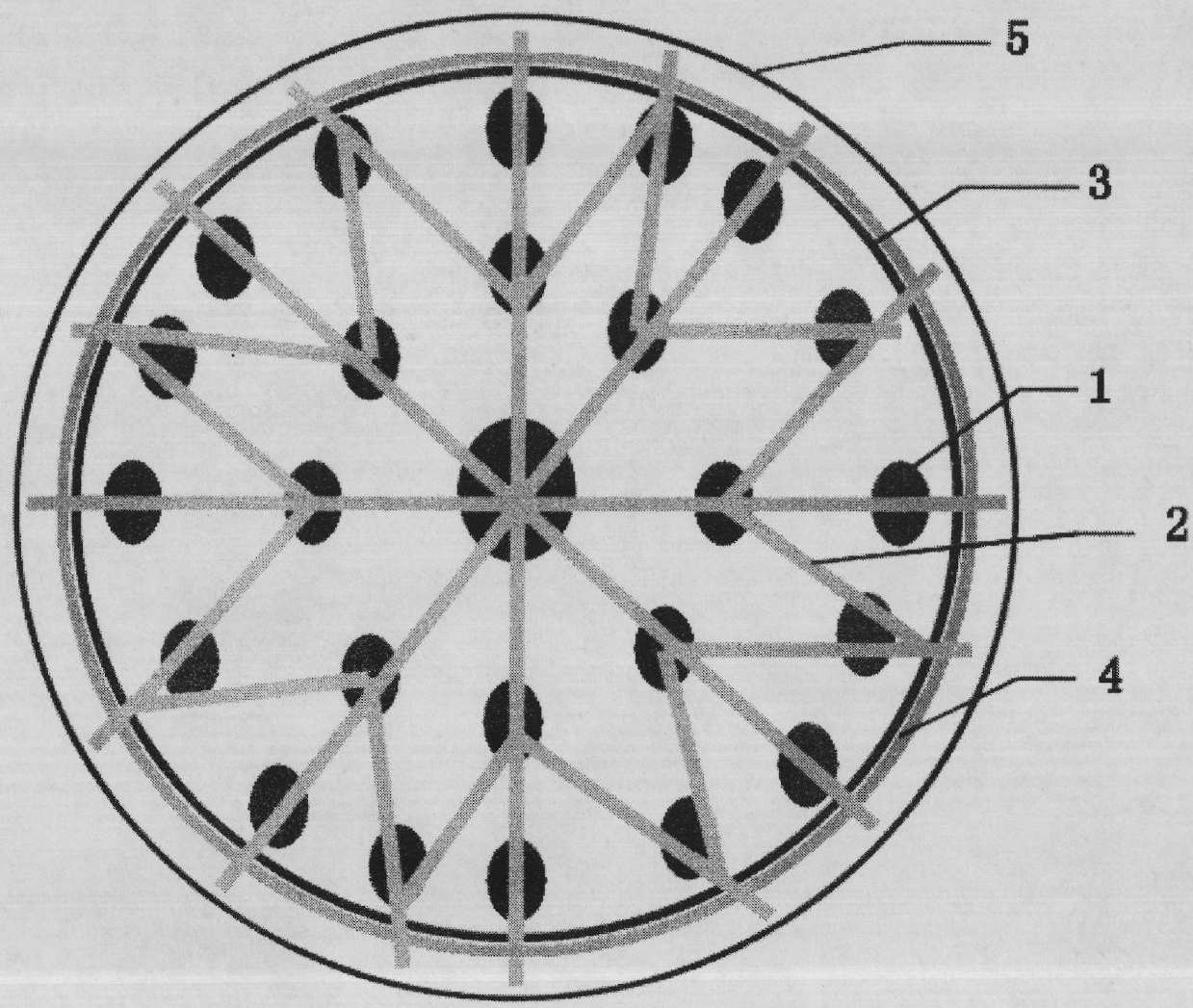

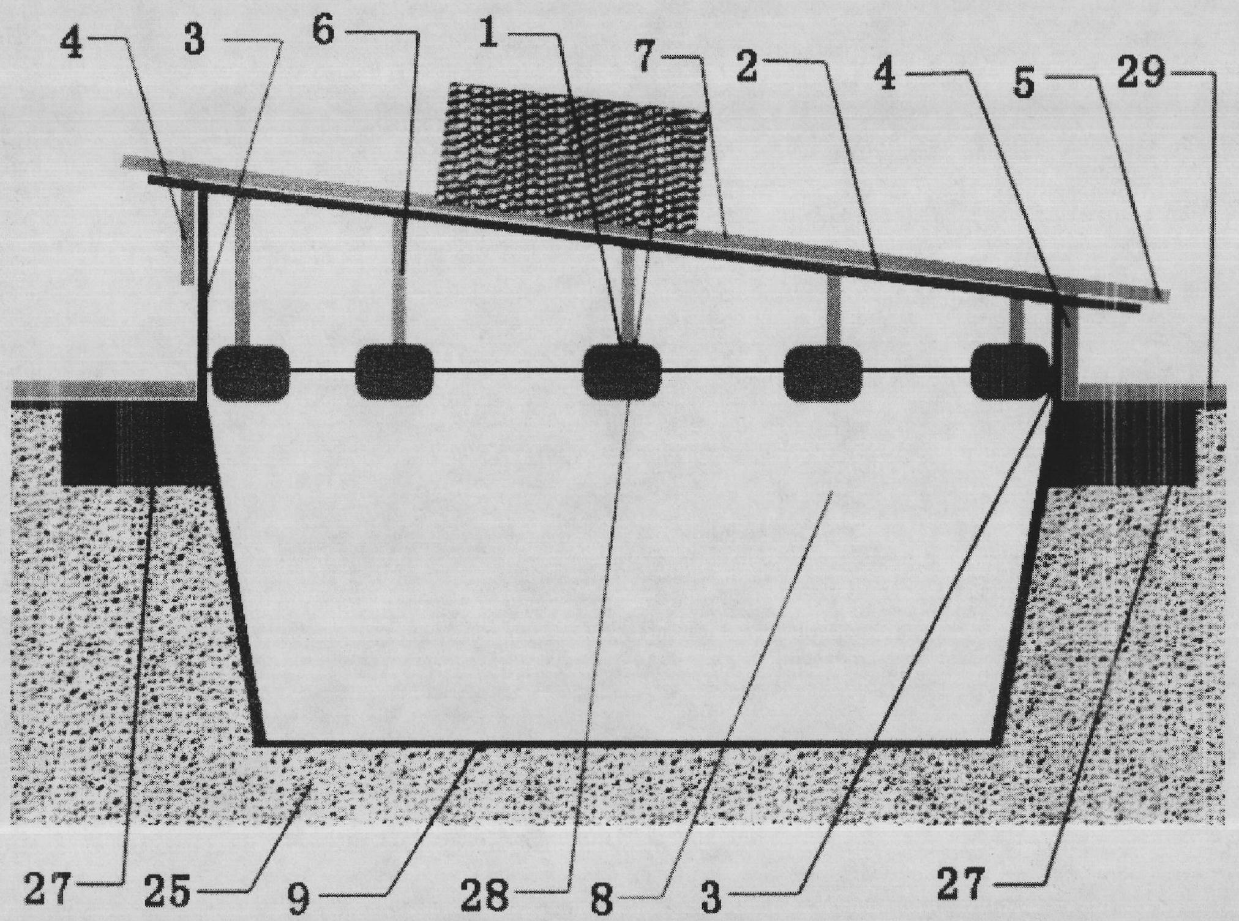

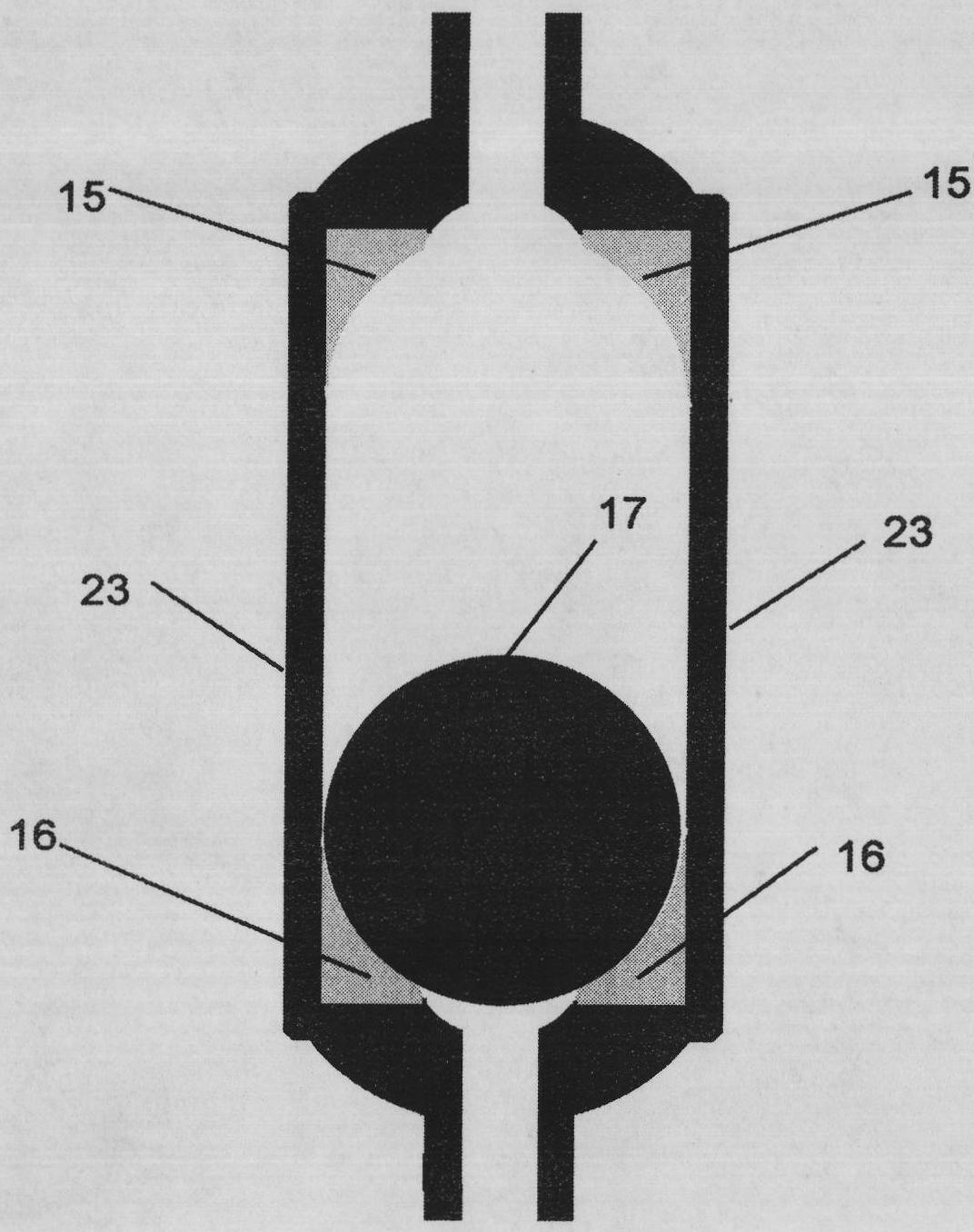

[0023] The thermal storage capacity is 10 million cubic meters. Before excavation, an annular trench with a cross-sectional area of 10 square meters is dug outside the pit foundation, and reinforced concrete is poured. After the reservoir is completed, the annular reinforced concrete circle becomes the outer surface of the pool wall 3. hoop27. In the earthwork masonry process of the reservoir, the vacuum insulation board 10 is first laid, and then the pool wall 3 and the pool bottom 9 are built; the vacuum insulation board 10 is an airtight layer sealing and wrapping the insulation board, and one end of the vacuum tube 11 is sealed and connected with the airtight layer. Its other end is connected with two-way check valve 12 tight or cut-off valve seal, is connected to vacuum pump 13 again. The heavy ball 17 in the two-way check valve 12 is closely attached to the lower cover 16 under the action of its own weight or the air pressure of the upper part and the lower part to pre...

Embodiment 2

[0025] The thermal storage capacity is 5 million cubic meters. Before excavation, an annular trench with a cross-sectional area of 6 square meters is dug outside the pit foundation, and reinforced concrete is poured. After the reservoir is completed, the annular reinforced concrete circle becomes the outer surface of the pool wall 3. hoop27. In the earthwork masonry process of the reservoir, the vacuum insulation board 10 is first laid, and then the pool wall 3 and the pool bottom 9 are built; the vacuum insulation board 10 is an airtight layer sealing and wrapping the insulation board, and one end of the vacuum tube 11 is sealed and connected with the airtight layer. Its other end is connected with two-way check valve 12 tight or cut-off valve seal, is connected to vacuum pump 13 again. The heavy ball 17 in the two-way check valve 12 is closely attached to the lower cover 16 under the action of its own weight or the air pressure of the upper part and the lower part to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com