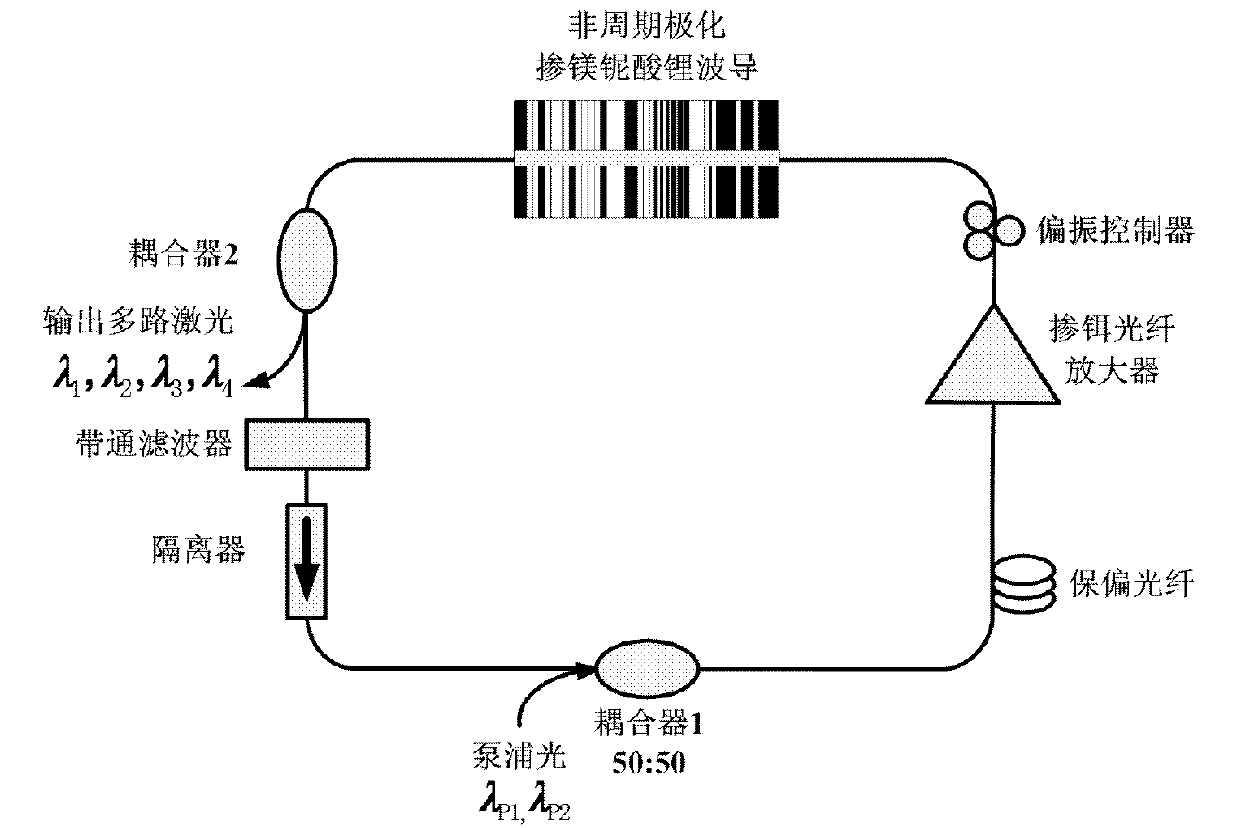

Method for preparing non-periodic optical superlattic titanium diffused waveguide

An optical superlattice, titanium diffusion technology, applied in lasers, laser parts, electrical components, etc., can solve the problems of complex structure, unadjustable wavelength interval of 18 output lasers, etc., to achieve the effect of easy integration and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

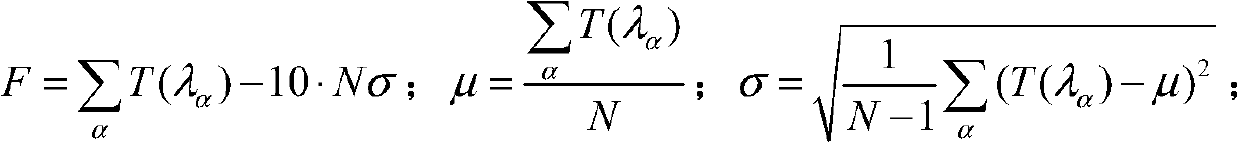

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0026] Select a Z-cut lithium niobate wafer with a magnesium-doped molar ratio of 5%, first fabricate a titanium diffusion waveguide structure on the -Z plane of the wafer, and then fabricate an aperiodic optical superlattice on the +Z plane of the wafer: by The wafer was polarized with an electric field at room temperature to achieve domain flipping of the crystal polarization.

[0027] The specific implementation steps are as follows:

[0028] (1) Choose a Z-cut magnesium-doped lithium niobate wafer with a size of 20x10x1mm and a thickness of 1mm with a 5% mol doping ratio. The + / -Z surfaces are all polished, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com