Sinter-hardening powder and their sintered compacts

A sintering hardening, powder technology, applied in the field of sintering hardening powder, can solve the problems of poor sintering density, poor compressibility mold wear, and reduced sinterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

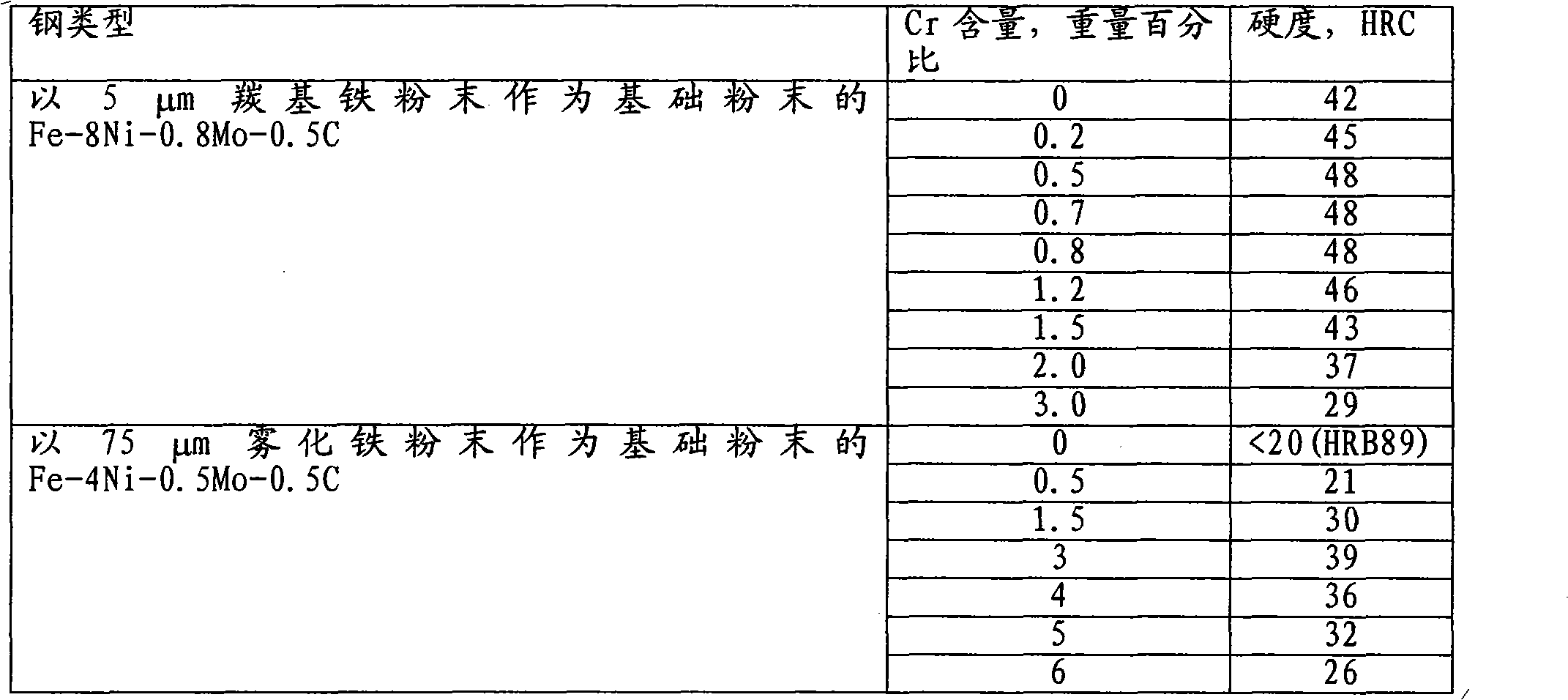

[0036]Following the composition of samples 1 and 2 listed in Table 2, water atomized iron powder was mixed with fine elements Ni, Mo, Cu and graphite powder, 0.8% zinc stearate (used as lubricant) and fine Fe-Cr or Fe-Si pre-alloyed powder mixing. The mixture was pressed, de-lubricated at 550°C for 15 minutes, and then sintered at 1200-1250°C. Sample Nos. 3, 4 and 5 used Fe-3Cr-0.5Mo as the base powder to which lubricant, elemental Ni, Cu powder, graphite powder and fine Fe-Mn pre-alloyed powder were added. Sample No. 6 was prepared by mixing lubricant, elemental Ni and graphite powders, and Fe-1.5Cr-0.2Mo pre-alloyed powders. To prepare samples Nos. 7, 8 and 9, 50% Fe-3Cr-0.5Mo powder and 50% Fe-1.5Cr-0.2Mo powder were mixed and then used as base powder. Different amounts of Ni and graphite powders were subsequently added to the base powder. The average particle size of the base powder is between 50 μm and 100 μm. All of these samples in Table 2 were sintered to approxima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com