Method for coproducing jerusalem artichoke inulin and jerusalem artichoke insoluble diedairy fiber

A technology of soluble dietary fiber and Jerusalem artichoke, applied in the field of fiber production, can solve the problems of preparing insoluble dietary fiber of Jerusalem artichoke, monotonous production products, etc., and achieve the effects of avoiding environmental pollution and resource waste, increasing equipment costs, and satisfying flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

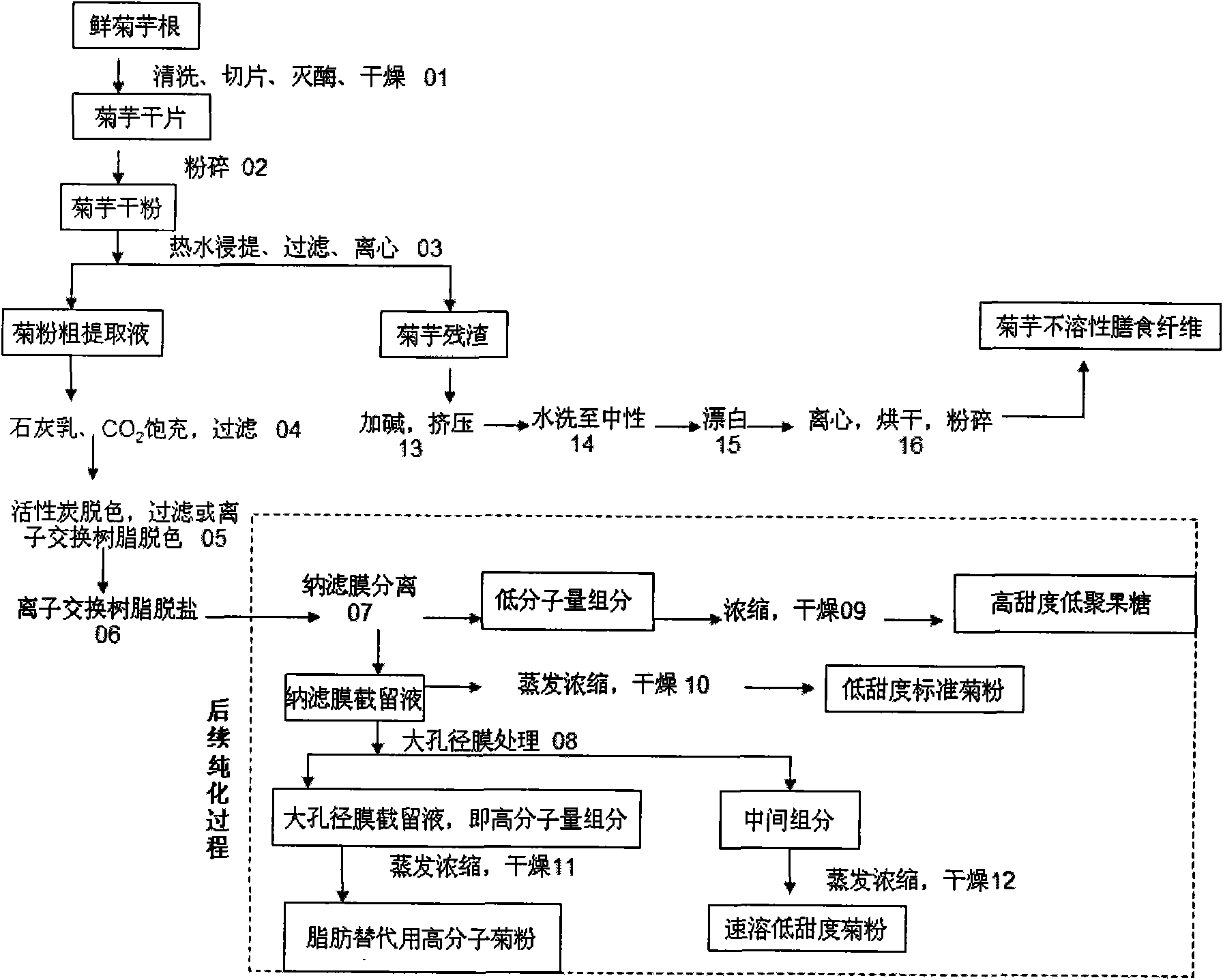

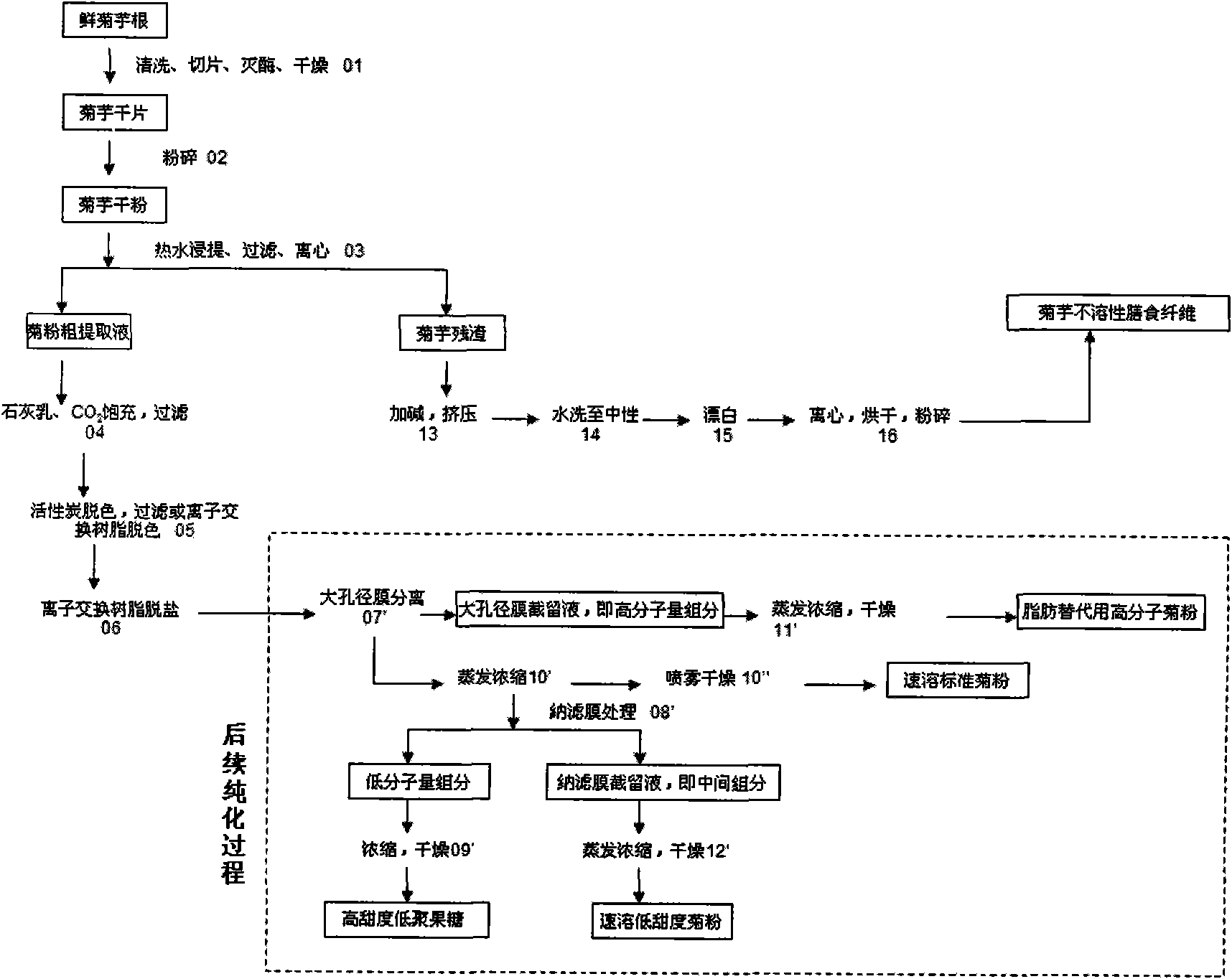

Method used

Image

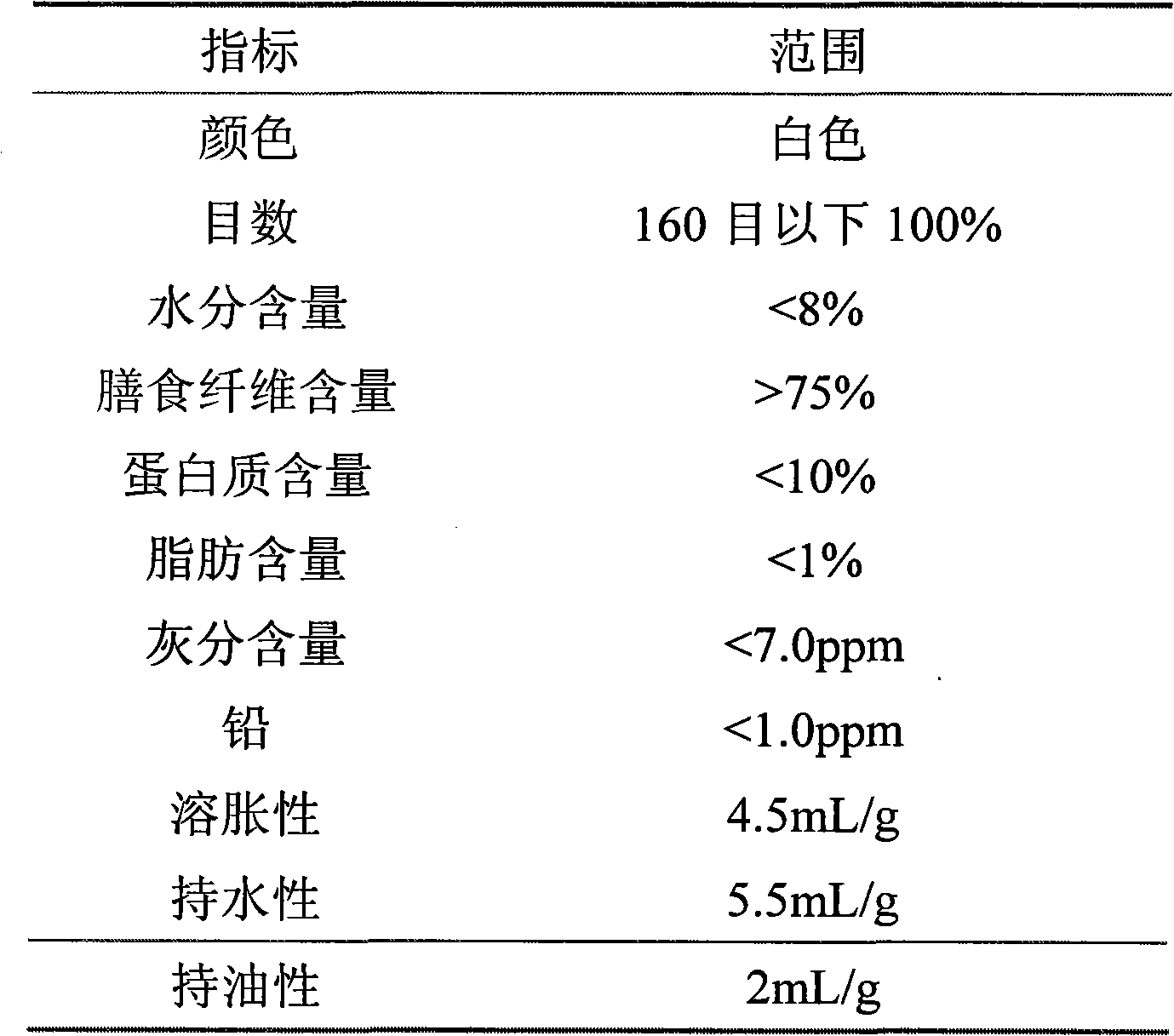

Examples

Embodiment 1

[0059] The fresh Jerusalem artichoke root is cleaned to remove soil, impurities, etc., and the Jerusalem artichoke root is cut into thin slices with a thickness of less than 0.2cm with a slicer. Jerusalem artichoke slices are steam blanched to kill enzymes, and the blanching time is 5 minutes. The Jerusalem artichoke chips after deenzyme are dried through a continuous dryer at a drying temperature of 50°C. The dried Jerusalem artichoke chips have no scorching, no discoloration flakes, good color and even moisture.

[0060] The dried Jerusalem artichoke chips are pulverized by a pulverizer to obtain dried Jerusalem artichoke powder, which has a moisture content of 10%, and then dried with a hot air continuous dryer until the moisture content is below 5%.

[0061] Add water to the dry Jerusalem artichoke powder, and fully stir at 60°C to make the dry Jerusalem artichoke powder absorb water and swell for leaching. Extraction is carried out with the aid of ultrasound. Add water...

Embodiment 2

[0074] The fresh Jerusalem artichoke root is cleaned to remove soil, impurities, etc., and the Jerusalem artichoke root is cut into thin slices with a thickness of less than 0.2cm by a slicer. Jerusalem artichoke slices are steam blanched to kill enzymes, and the blanching time is 3 minutes. The Jerusalem artichoke chips after deenzyme are dried by a continuous dryer at a drying temperature of 60°C.

[0075] The dried Jerusalem artichoke chips are pulverized by a pulverizer to obtain dry Jerusalem artichoke powder, and the moisture content of the dry Jerusalem artichoke powder is 5%.

[0076] Add water to the dry Jerusalem artichoke powder, and fully stir at 70°C to make the dried Jerusalem artichoke powder absorb water and swell for extraction. Extraction was performed using the aid of microwaves. Add water 5 times, that is, add water to extract and filter, and add water to the residue to repeat the extraction. The total amount of water added is controlled at 10 times of J...

Embodiment 3

[0088] The fresh Jerusalem artichoke root is cleaned to remove soil, impurities, etc., and the Jerusalem artichoke root is cut into thin slices with a thickness of less than 0.2cm by a slicer. Jerusalem artichoke slices are steam blanched to kill enzymes, and the blanching time is 5 minutes. The Jerusalem artichoke chips after deenzyme are dried through a continuous dryer at a drying temperature of 50°C.

[0089] The dried Jerusalem artichoke chips are pulverized by a pulverizer to obtain dry Jerusalem artichoke powder, and the moisture content of the dry Jerusalem artichoke powder is 5%.

[0090] Add water to the dry Jerusalem artichoke powder, and fully stir at 70°C to make the dried Jerusalem artichoke powder absorb water and swell for extraction. Extraction was performed using the aid of microwaves. Add water for 3 times, that is, add water to extract and filter, and add water to the residue again to repeat the leaching. The total amount of water added is controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com