Heavy-draft truss upright-column combined platform

A water truss and combined technology, which is applied in the field of deep-draft truss-column combined platform, can solve the problems of difficult design, poor heaving motion performance, and high price, so as to improve the ability to adapt to harsh marine environments and improve the overall structure Stiffness and Strength, Effect of Reducing Fatigue Hot Spot Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

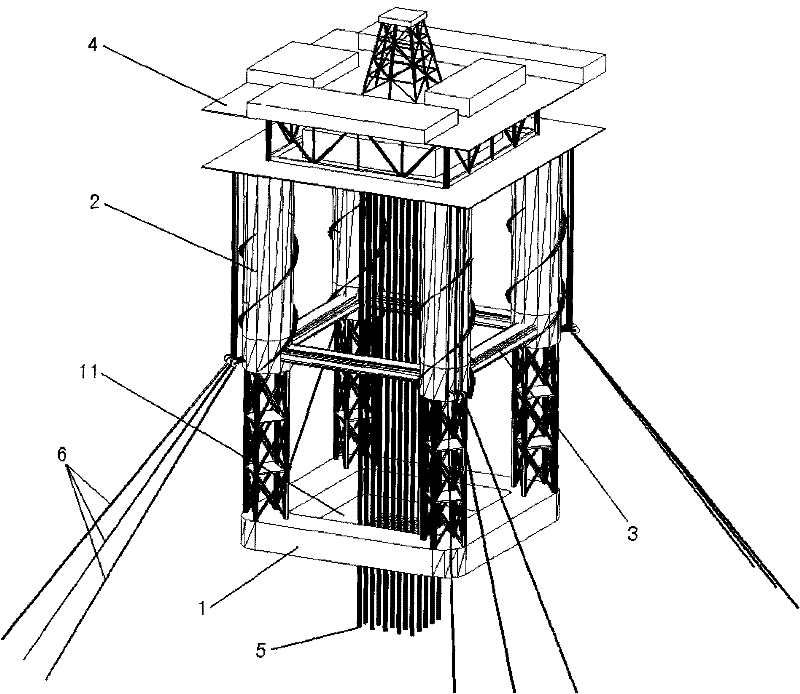

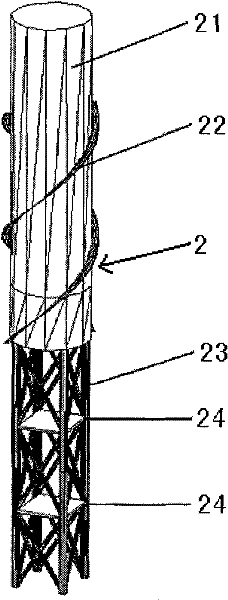

[0017] Such as figure 1 As shown, the present invention comprises a square or approximately square annular ballast tank 1, four vertical columns 2 positioned at corners of the annular ballast tank 1, four buoyant tank structures 3 positioned at the middle of the column 2 and a The drilling rig and the oil and gas processing module 4 located on the top of the column 2.

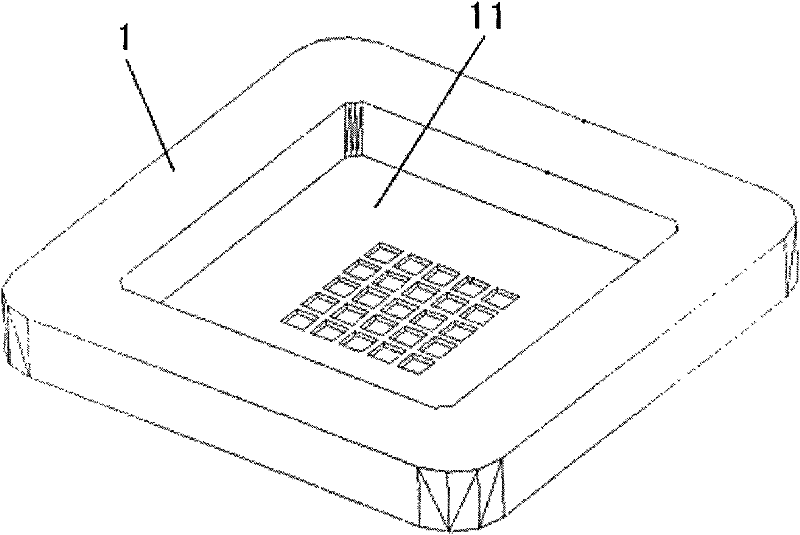

[0018] Such as figure 2 As shown, the annular ballast tank 1 adopts a permanent fixed ballast method, and the tank is filled with iron ore or other heavy objects to ensure that the buoyancy center of the platform is higher than the center of gravity at any time, so that the platform maintains a relatively deep draft during service , which not only realizes the unconditional stability of the platform in the marine environment, but also ensures that the stability and seakeeping of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com