Synthesis of high activity ZSM-48

A ZSM-48, water-based technology used in the synthesis of highly active ZSM-48 and its use as a catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Use diquat-5 and low OH - / SiO 2 Recently prepared highly active ZSM-48

[0077] A mixture was prepared from 1040 g water, 45 g pentamethyl onium dibromide (50% solution), 200 g Ultrasil silica, 11 g sodium aluminate solution (45%) and 36 g 50% sodium hydroxide solution. 5 g of ZSM-48 seeds were then added to the mixture. The mixture has the following molar composition:

[0078] SiO 2 / Al 2 O 3 : 102

[0079] H 2 O / SiO 2 : 20

[0080] OH - / SiO 2 : 0.17

[0081] Na + / SiO 2 : 0.17

[0082] Chlorpyrifos-5 / SiO 2 : 0.02

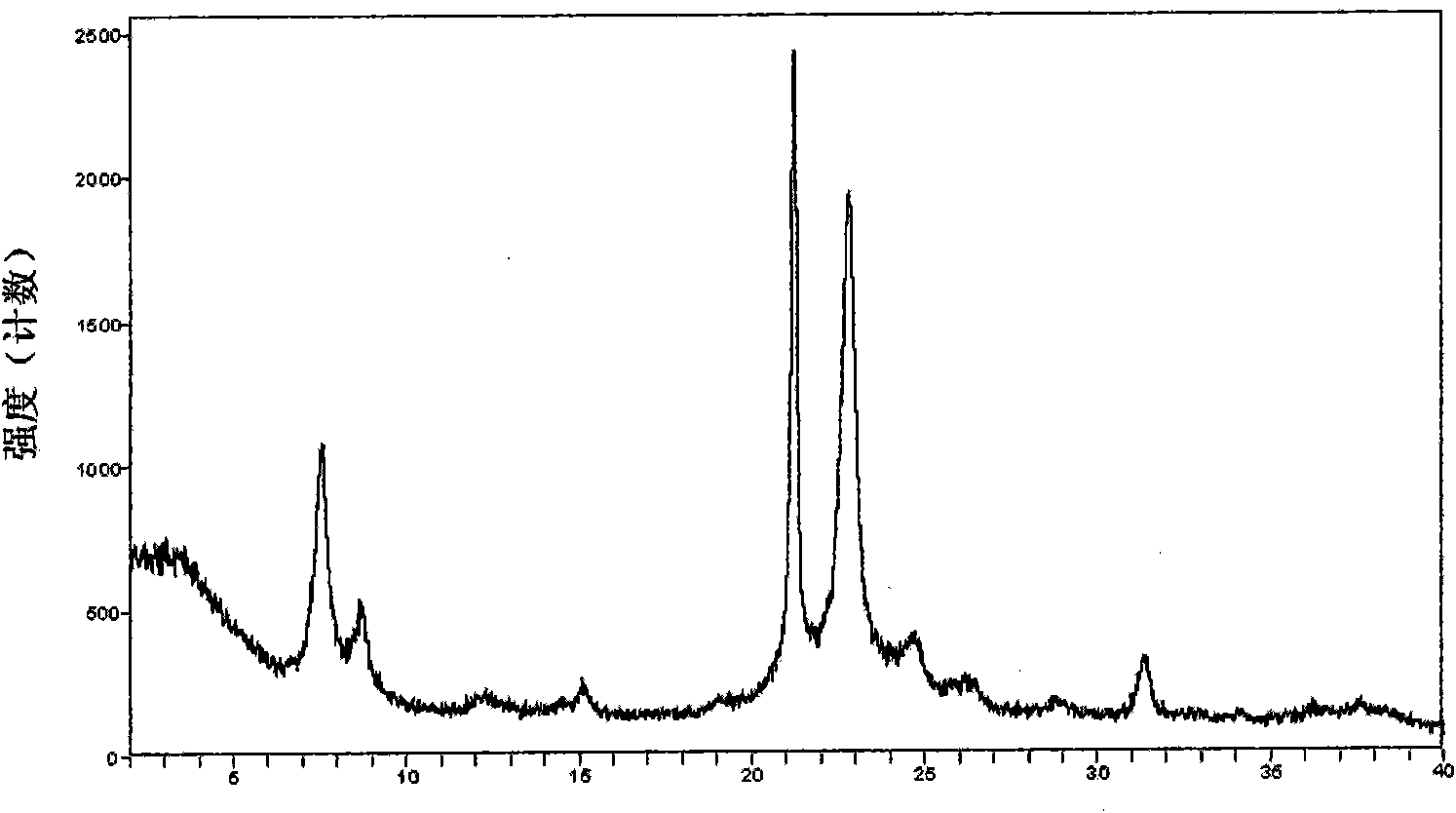

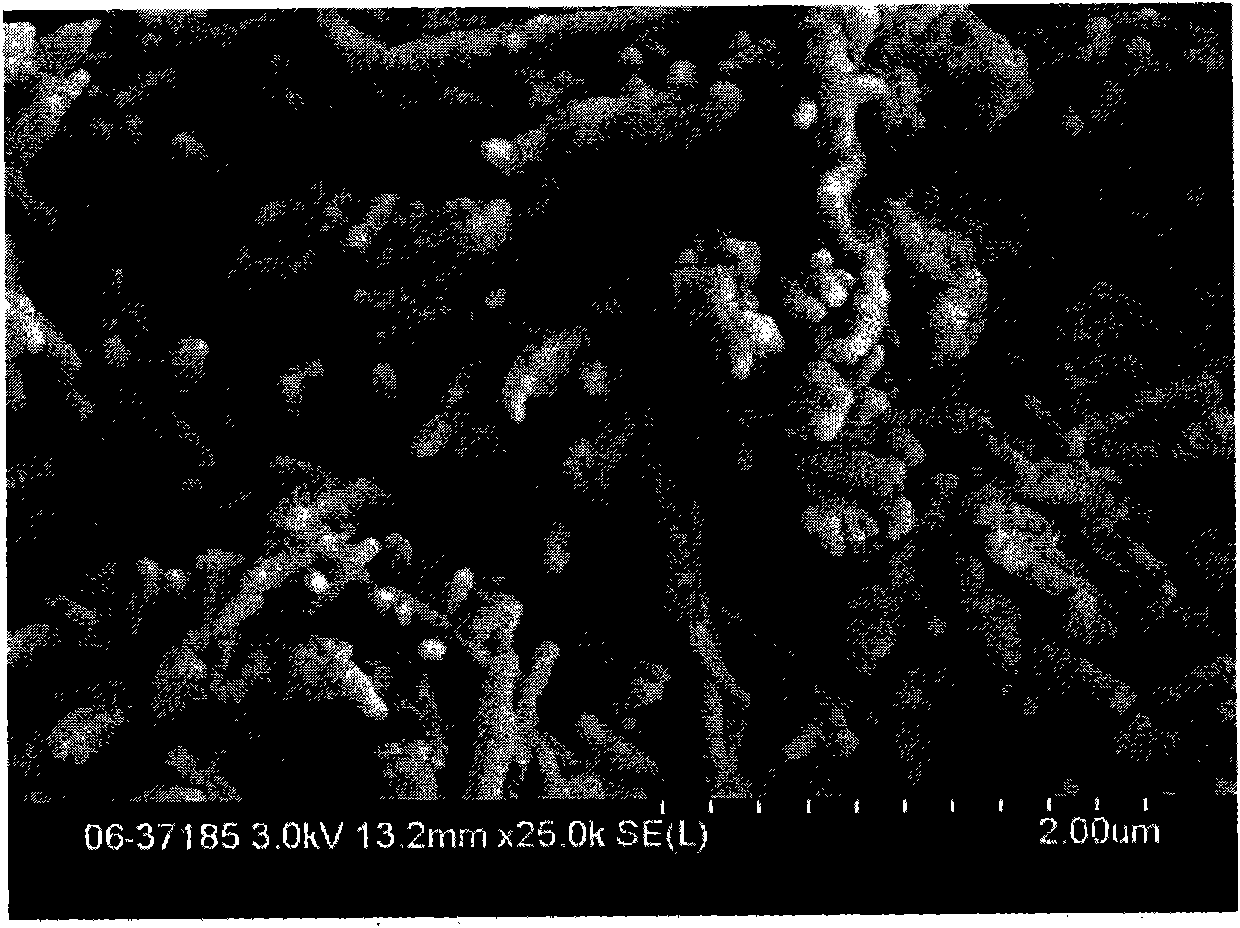

[0083] The mixture was reacted at 320°F (160°C) for 48 hours in a 2 liter autoclave stirred at 350 RPM. The product was filtered, washed with deionized (DI) water and dried at 250°F (120°C). XRD patterns of synthetic materials (see Figure 1A ) shows the typical pure phase of ZSM-48 topology. SEM of the composite material (see Figure 1B ) shows that the material consists of agglomerates of elongated needle-like crysta...

Embodiment 2

[0084] Example 2 (comparative example)

[0085] Use diquat-5, low OH - / SiO 2 SiO with high ratio and 2 / Al 2 O 3 to prepare the active ZSM-48

[0086] A mixture was prepared from 1100 g water, 65 g pentamethyl onium dibromide (50% solution), 228 g Ultrasil silica, 6 g sodium aluminate solution (45%) and 45 g 50% sodium hydroxide solution. The mixture has the following molar composition:

[0087] SiO 2 / Al 2 O 3 : 195

[0088] H 2 O / SiO 2 : 19

[0089] OH - / SiO 2 : 0.17

[0090] Na + / SiO 2 : 0.17

[0091] Chlorpyrifos-5 / SiO 2 : 0.027

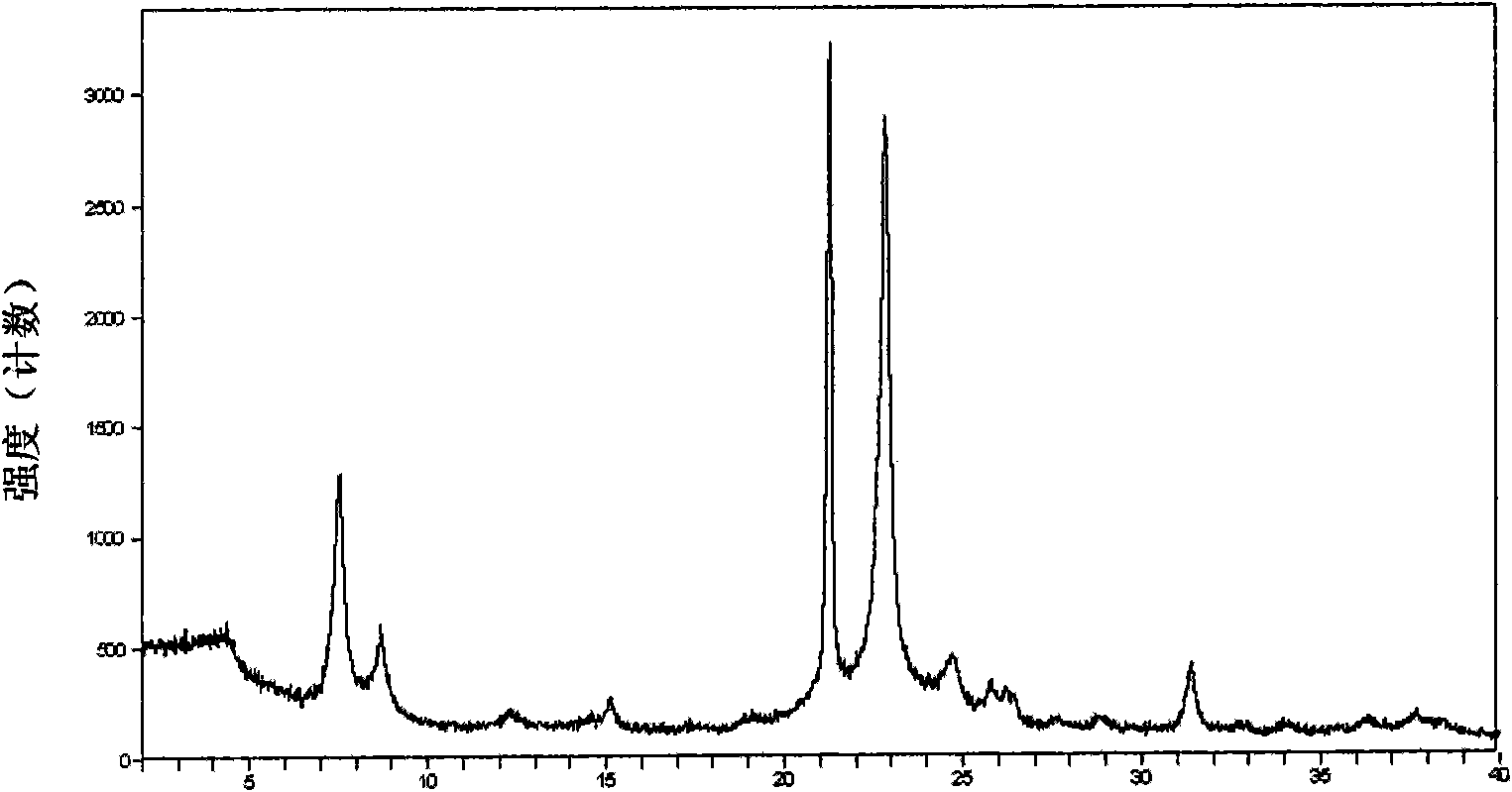

[0092] The mixture was reacted at 320°F (160°C) for 48 hours in a 2 liter autoclave stirred at 350 RPM. The product was filtered, washed with deionized (DI) water and dried at 250°F (120°C). XRD patterns of synthetic materials (see Figure 2A ) shows the typical pure phase of ZSM-48 topology. SEM of the composite material (see Figure 2B ) shows that the material consists of agglomerate...

Embodiment 3

[0093] Example 3 (comparative example)

[0094] Use diquat-5 and high OH - / SiO 2 Recently prepared highly active ZSM-48

[0095] From 360g water, 39g pentamethylonium dibromide (50% solution), 35.6g Aerosil 130 silica, 6.9g Al(NO 3 ) 3 .xH 2 O and 14.4 g of a 50% sodium hydroxide solution to prepare a mixture. 5 g of ZSM-48 seeds were then added to the mixture. The mixture has the following molar composition:

[0096] SiO 2 / Al 2 O 3 : 60

[0097] H 2 O / SiO 2 : 40

[0098] OH - / SiO 2 : 0.33

[0099] Na + / SiO 2 : 0.33

[0100] Chlorpyrifos-5 / SiO 2 : 0.1

[0101] The mixture was aged at room temperature with stirring at 100 RPM and then reacted in a 600 ml autoclave at 320°F (160°C) for 96 hours with stirring at 100 RPM. The product was filtered, washed with deionized (DI) water and dried at 250°F (120°C). The XRD patterns of the synthesized materials show typical phases of the ZSM-48 topology. SEM of the composite materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com