Machine vision belt tearing detecting and protecting device

A technology of machine vision and protection devices, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of cumbersome maintenance, high cost, and inability to ensure accurate belt tear detection in the later period, so as to avoid instability performance, to ensure the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

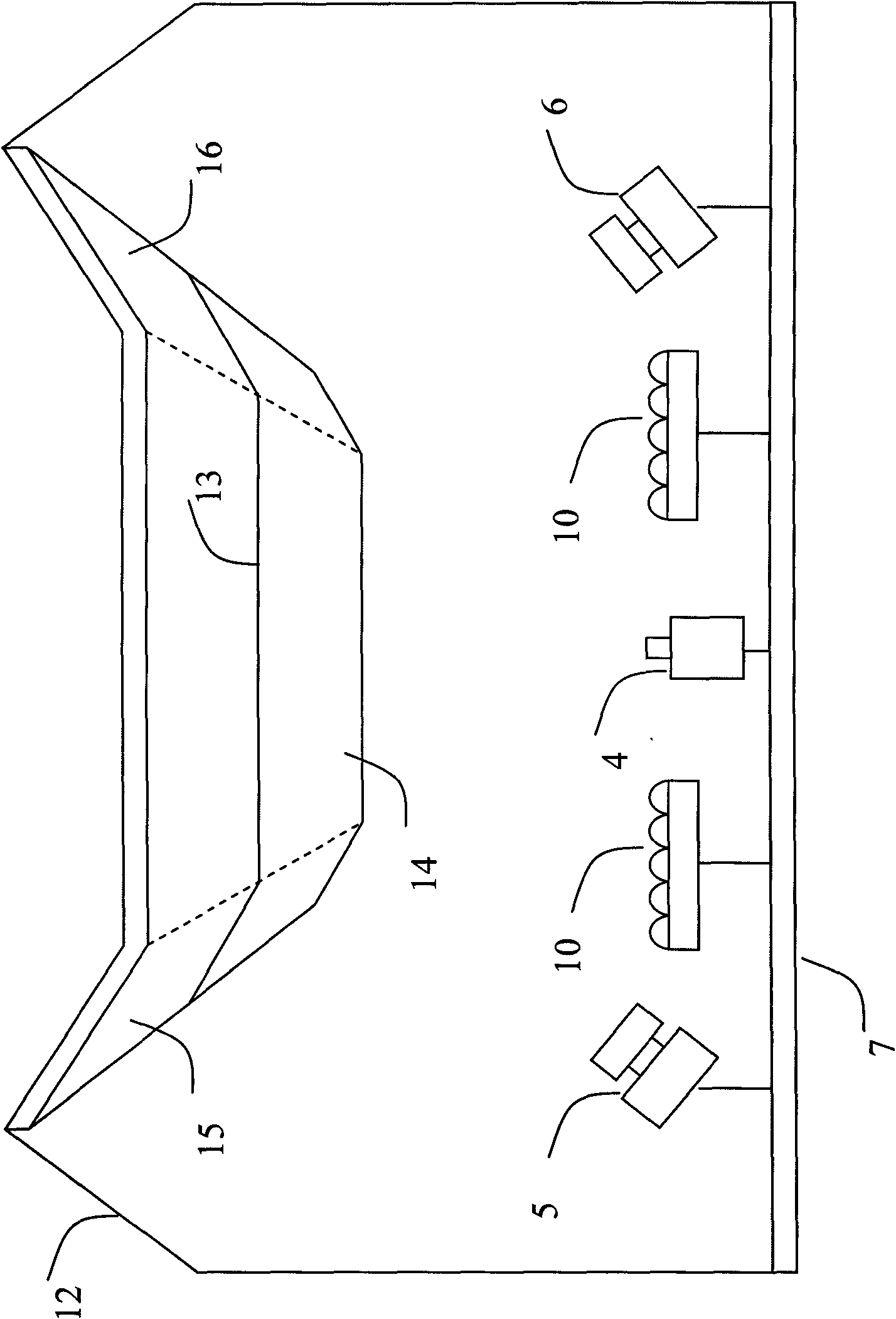

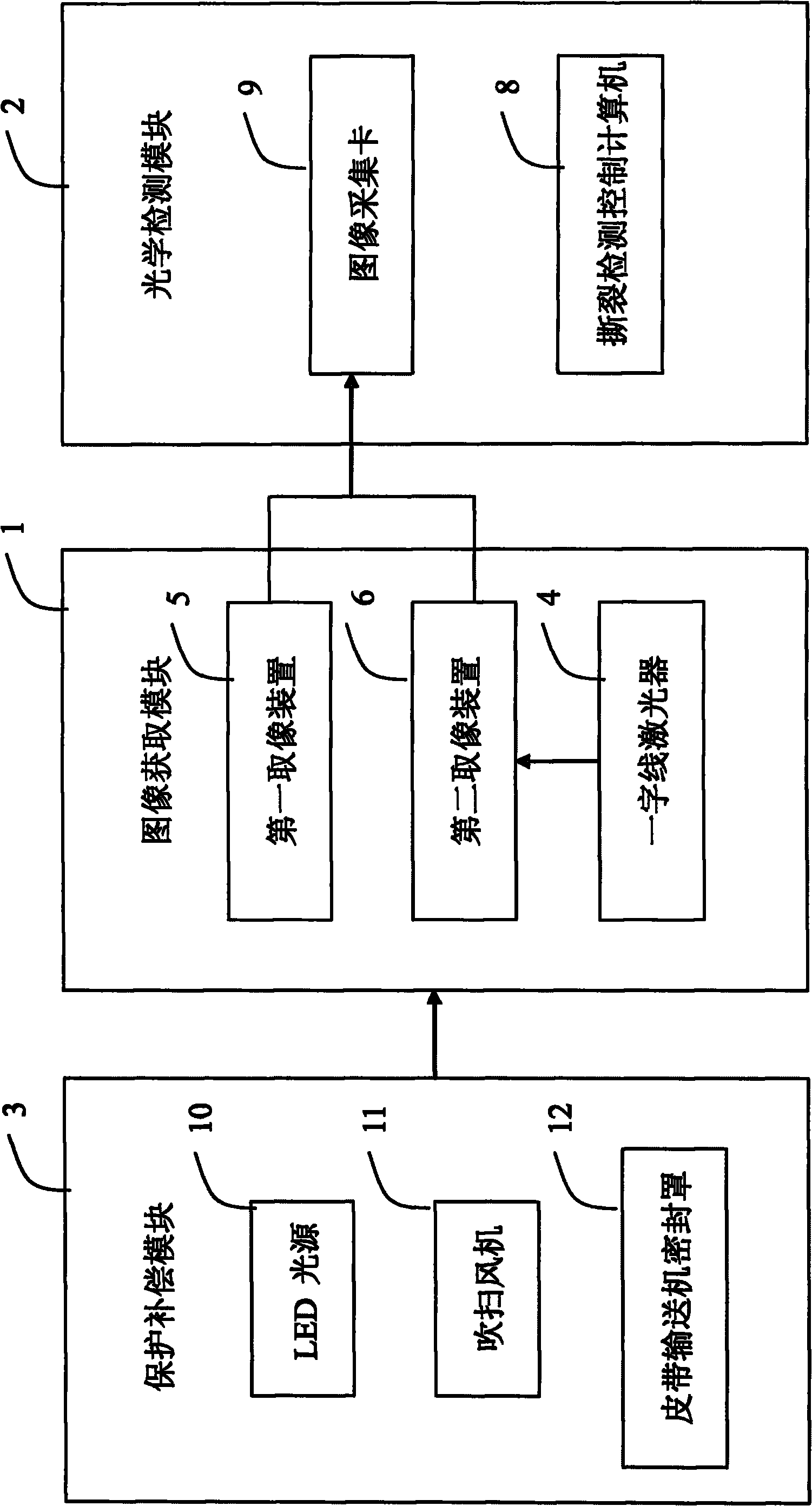

[0028] The technical solution adopted by the present invention to solve the technical problem is: the machine vision belt tear detection device of the present invention is composed of three modules: an image acquisition module 1, an optical detection module 2, and a protection compensation module 3.

[0029] The image acquisition module 1 is composed of a word-line laser 4, a first imaging device 5, a second imaging device 6 and a machine base 7, and its purpose is to transmit the belt surface image to the optical detection module in real time for tearing Online detection of accidents. The one-line laser 4 projects a red laser stripe with a wavelength of 650nm to the bottom of the belt as structured light for auxiliary measurement, and the direction of the laser line is perpendicular to the belt transmission direction. The first imaging device 5 and the second imaging device 6 are respectively installed at the left and right ends under the belt, and their optical axes intersec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com