Low-temperature preparation method and application of vanadium dioxide film

The technology of vanadium dioxide and thin film is applied in the field of low-temperature preparation of vanadium dioxide thin film, which can solve the problems of high phase transition temperature and high synthesis temperature of vanadium dioxide thin film, and achieve the advantages of easy large-area preparation, low sintering temperature and convenient coating operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

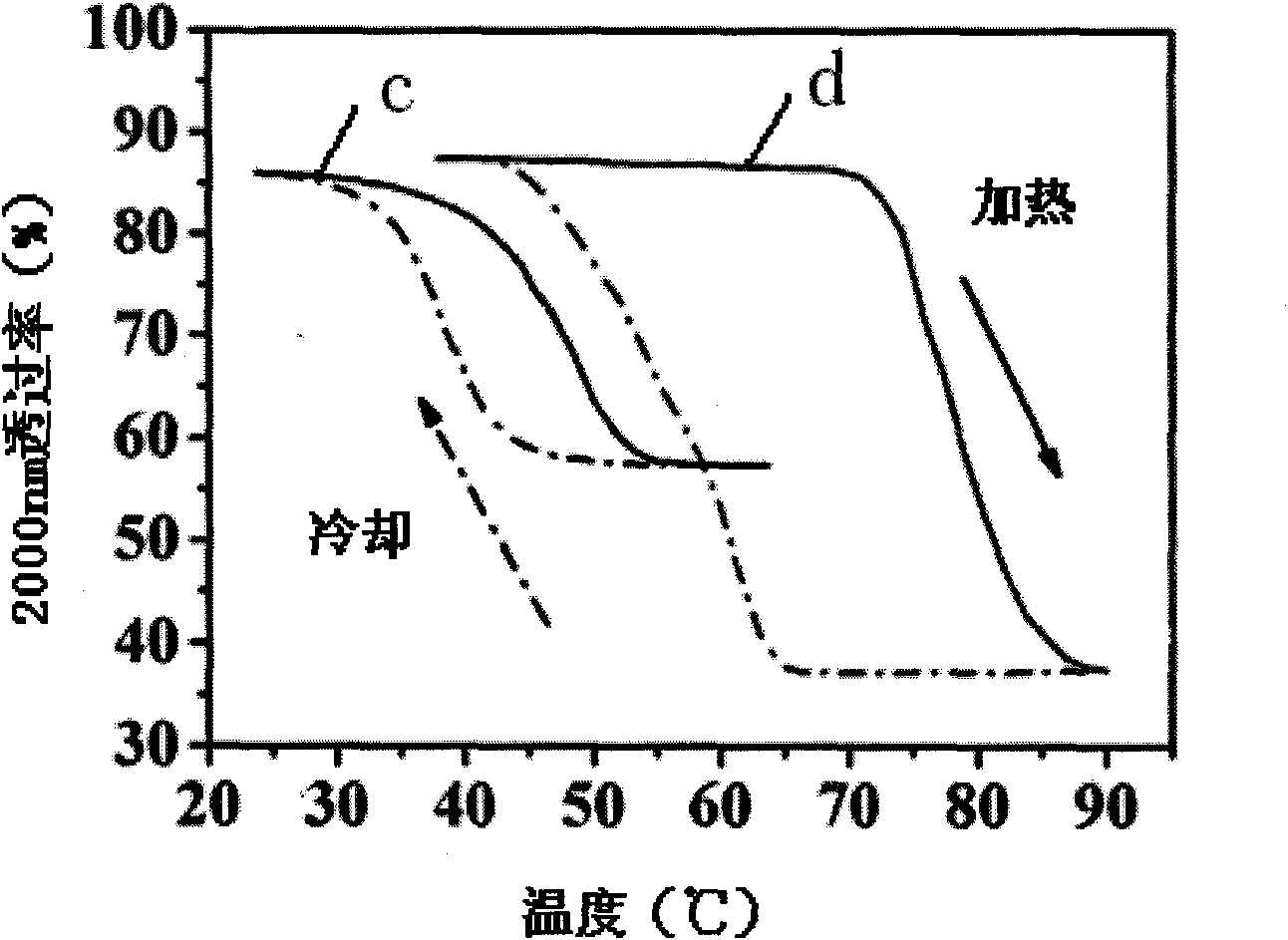

[0031] Preparation of Vanadium Dioxide Thin Film with Phase Transition Temperature of 42.1℃

[0032] (1) Preparation of coating solution:

[0033] Take 13.3 g of vanadyl acetylacetonate, dissolve it in 100 ml of a mixed solution of ethanol, ethylene glycol, chloroform, and water with a volume ratio of 2:4:1:1, stir in a magnetic stirrer for 3 hours, and age for 3 hours Finally, the coating solution of the vanadium dioxide thin film is obtained.

[0034] (2) Clean the substrate:

[0035] Select the substrate as quartz glass, and use the standard RCA process to clean it to remove organic matter, dust and metal ion impurities on the surface. After that, put the substrate into a 60°C oven for drying treatment before use.

[0036] (3) Coating solution coating

[0037] Select the coating solution obtained in the above step (1), and use a spin coater for coating. The spin coating speed and time are as follows: first, the low speed is 200 rpm, and it is kept for 10 seconds; then,...

Embodiment 2

[0043] Preparation of Vanadium Dioxide Thin Film with Phase Transition Temperature of 67.3℃

[0044] (1) Preparation of coating solution:

[0045] Take 13.3 g of vanadyl acetylacetonate, dissolve it in 100 ml of a mixed solution of ethanol, ethylene glycol, chloroform, and water with a volume ratio of 2:4:1:1, stir in a magnetic stirrer for 3 hours, and age for a week A coating solution for the vanadium dioxide thin film is obtained.

[0046] (2) Clean the substrate:

[0047]Select the substrate as quartz glass, and use the standard RCA process to clean it to remove organic matter, dust and metal ion impurities on the surface. Afterwards, the substrate was dried in an oven at 60°C for use.

[0048] (3) Coating solution coating

[0049] Select the coating solution obtained in the above step (1), and use a spin coater for coating. The spin coating speed and time are as follows: first, the low speed is 200 rpm, and it is kept for 10 seconds; then, the high speed is 3000 rpm,...

Embodiment 3

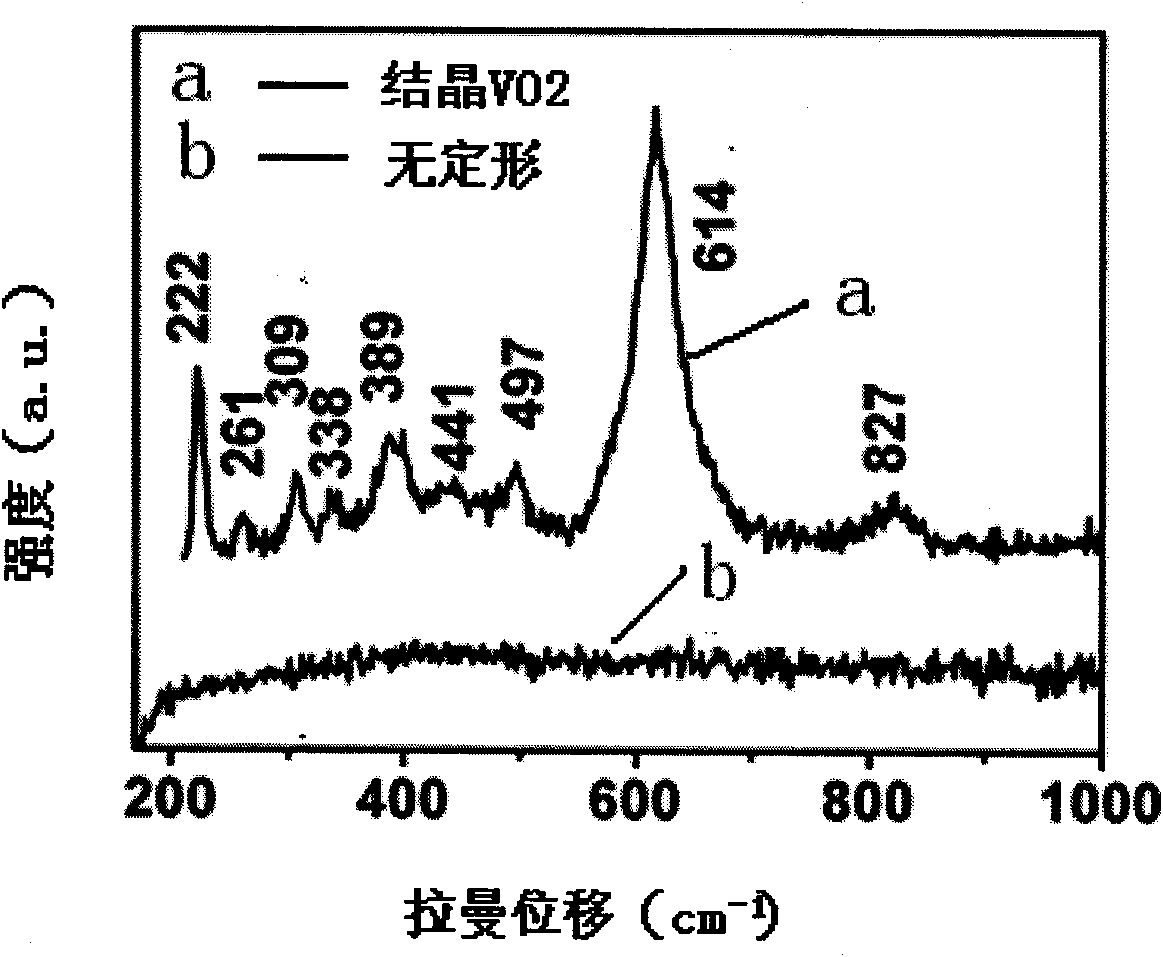

[0054] Preparation of Vanadium Dioxide Thin Films Sintered at 250℃

[0055] (1) Preparation of coating solution:

[0056] Take 13.3 g of vanadyl acetylacetonate, dissolve it into 100 ml of a mixed solution of ethanol, ethylene glycol, chloroform, and water with a volume ratio of 2:4:1:1, stir in a magnetic stirrer for 3 hours, and obtain after aging for one week Coating solution for vanadium dioxide thin film.

[0057] (2) Clean the substrate:

[0058] Select the substrate as quartz glass, and use the standard RCA process to clean it to remove organic matter, dust and metal ion impurities on the surface. Afterwards, the substrate was dried in an oven at 60°C for use.

[0059] (3) Coating solution coating

[0060] Select the coating solution obtained in the above step (1), and use a spin coater for coating. The spin coating speed and time are as follows: first, the low speed is 200 rpm, and it is kept for 10 seconds; then, the high speed is 3000 rpm, and it is kept for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com